Current is the flow of electron through a conductor. Due to the internal resistance of conductors the kinetic energy of electrons will convert into thermal energy. When the current is high enough the generated heat could melt the metal conductor. This is the basic principle of spot welding.

Electrodes of spot welders are made from highly conductive metals like copper to keep them from melting.

Transformers in microwave ovens are designed to step up the mains voltage to 2kV. By replacing the secondary coil with a coil of fewer turns, the output voltage can be stepped down.

Since the input and the output power should be the same, by decreasing the voltage it will be able to produce a large amount of current. To accommodate this current, a large diameter wire must be used. I've used a 25 mm² wire and it produced about 2.6V at the output. Since this voltage is very low, it is not enough to shock someone.

To control the amount of time for a weld, a timer module(XY-WJ01) was employed. The minimum delay period is 0.01s. So the power that goes into a weld can be adjusted accordingly.

The enclosure and the foot-switch were 3D printed. The handle of the enclosure is reinforced by nuts and screws.

The design of the foot-switch is inspired by Adafruit's USB foot-switch design. A 3.5mm headphone jack is used to connect the foot-switch to the welder.

Update: 06.03.2020

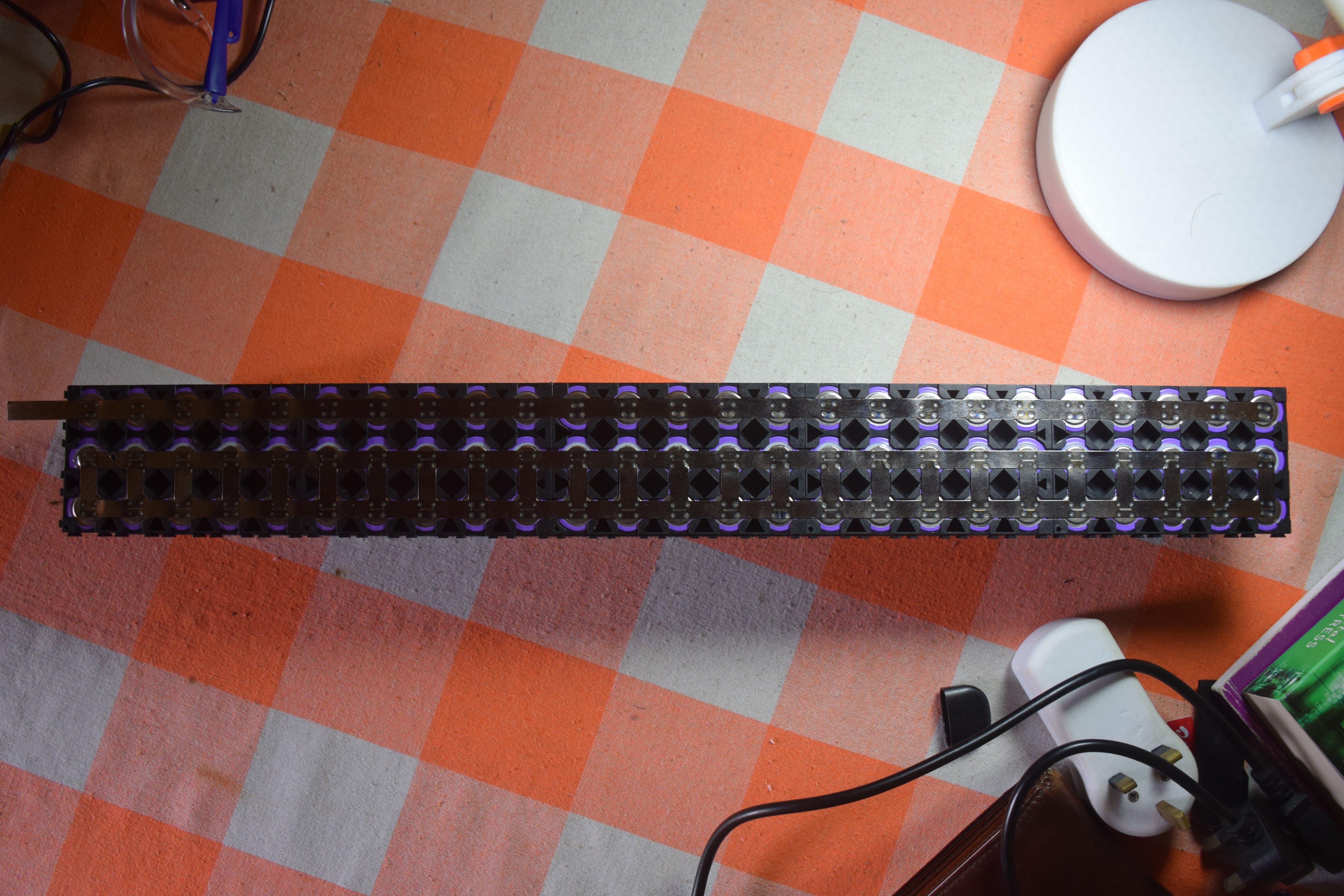

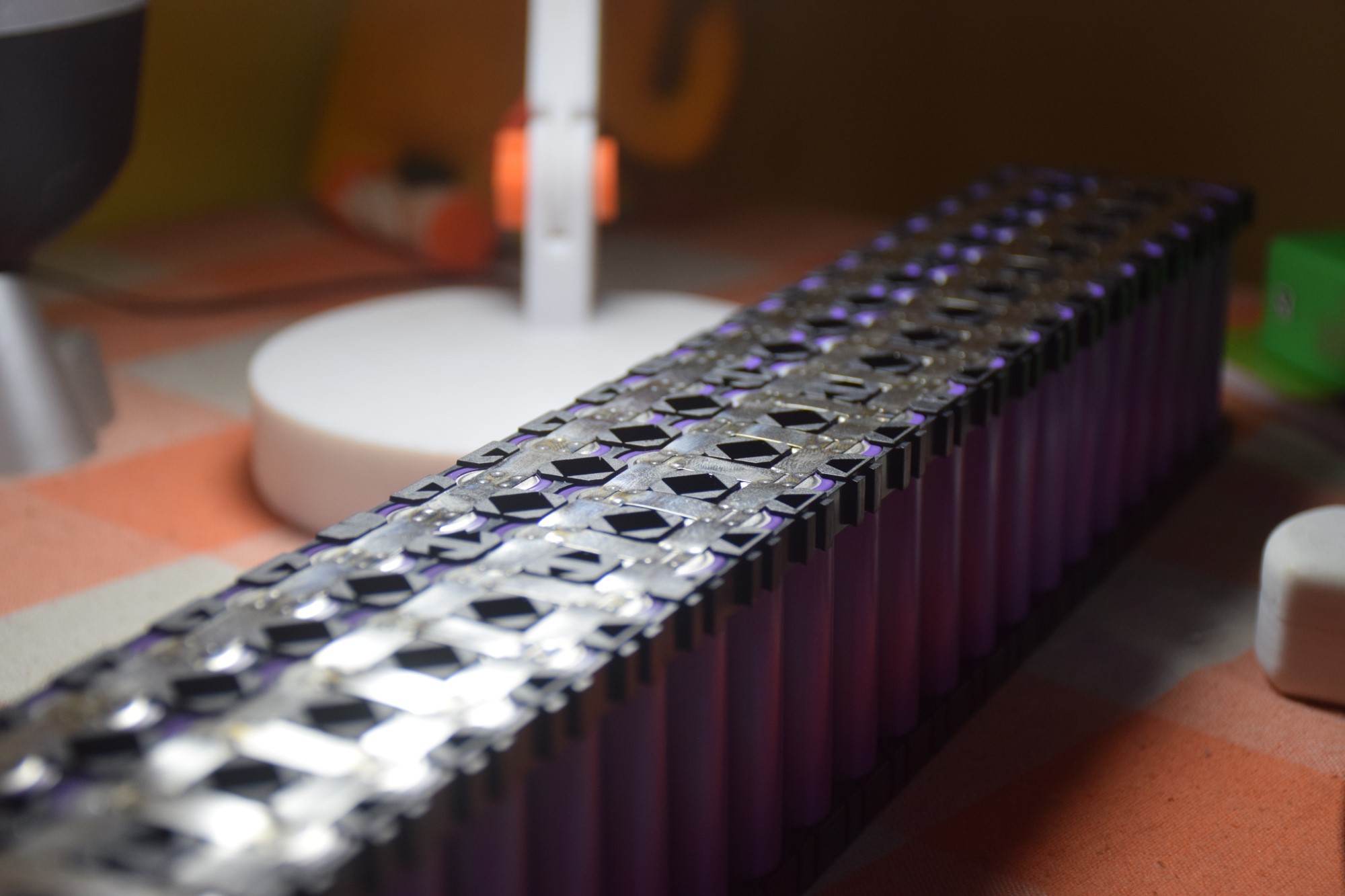

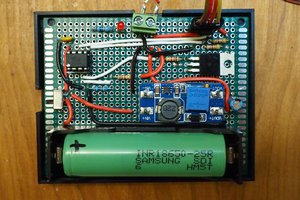

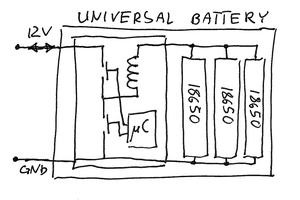

This battery pack was built by using the spot welder to use in the backup battery pack project.

Anuradha Gunawardhana

Anuradha Gunawardhana

Jeff Wahaus

Jeff Wahaus

dave.m.mcdonough

dave.m.mcdonough

Ted Yapo

Ted Yapo

the two electrodes need to clamp the objects to be welded together, can't remember LB's but much like a vice grip, this will be the hardest part of the build