Preliminary version of UI for the test setup done.

It takes more time then I expected (around 14 hours).

It looks ugly, but I think functional enough.

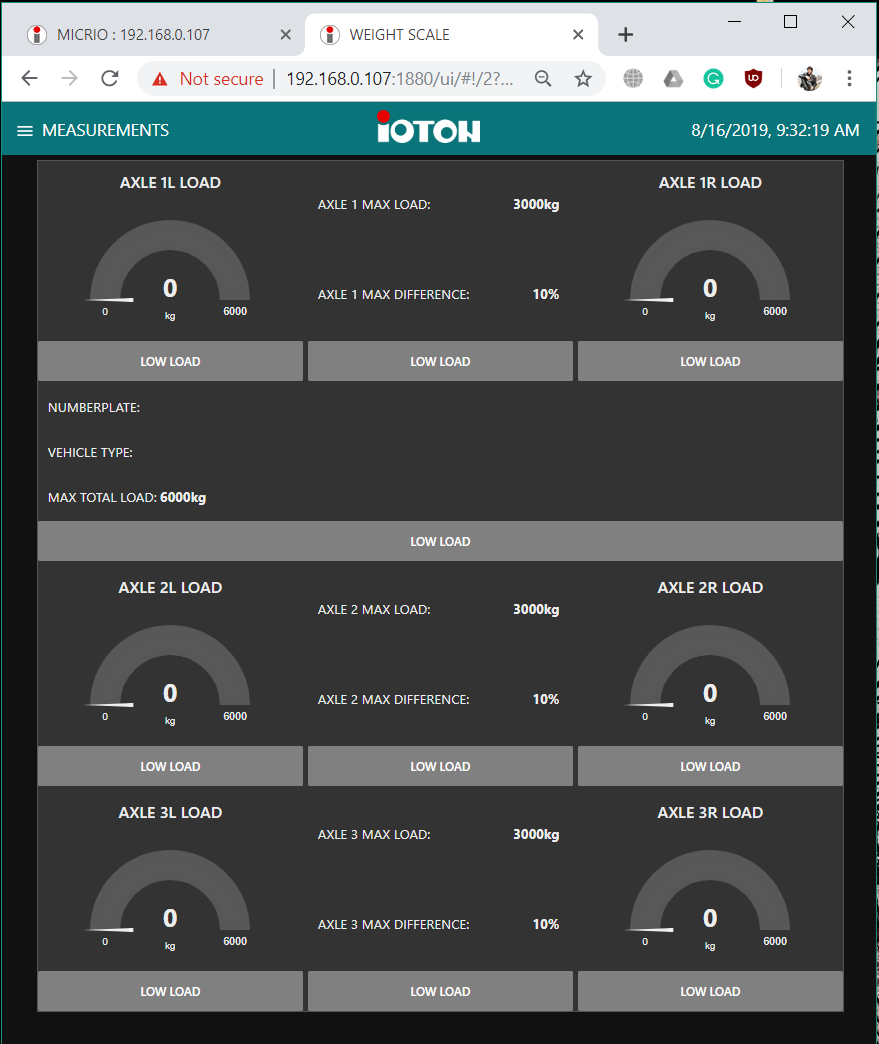

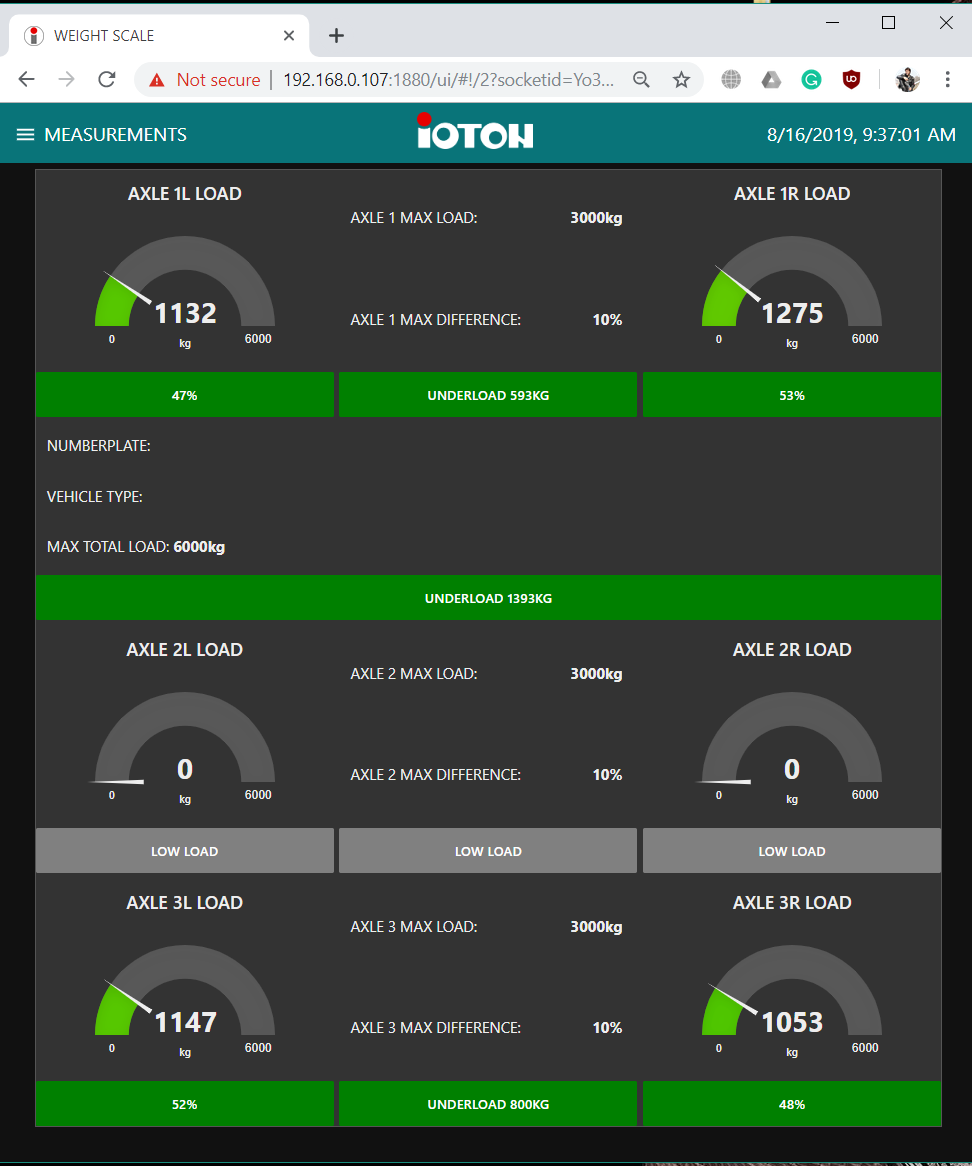

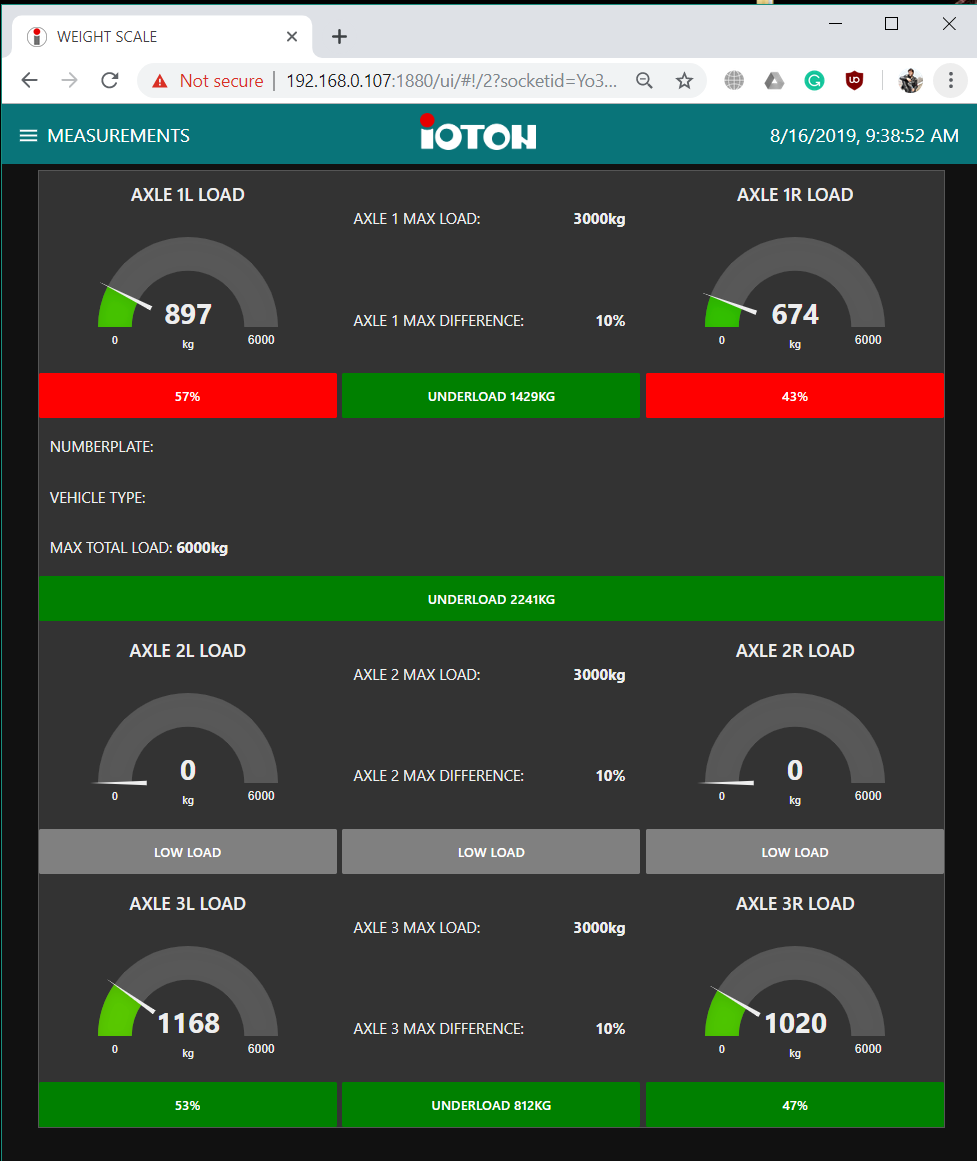

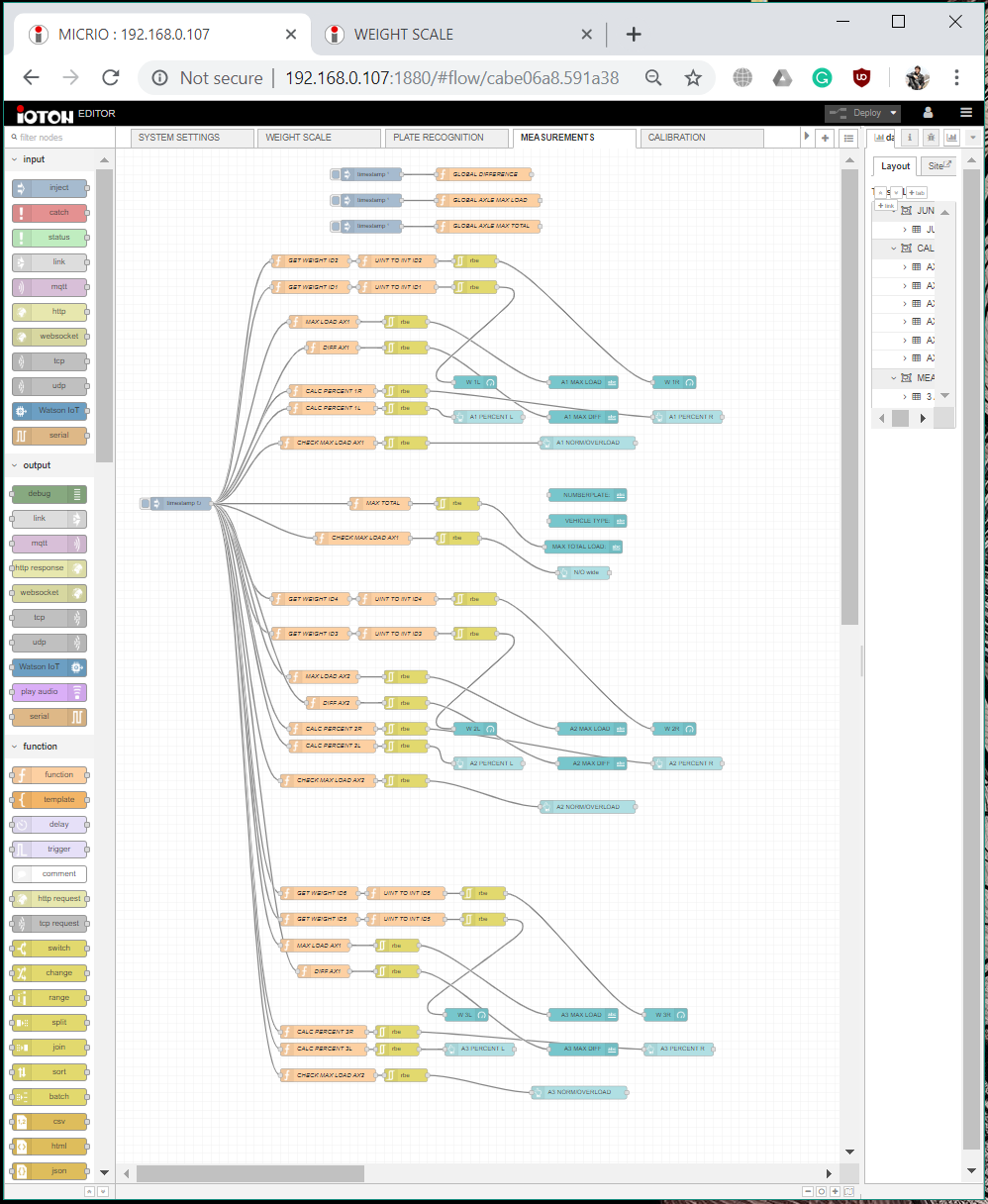

Measurement tab:

- Load gauge for each truck wheel

- Total truck load

- Overload/underload data and signalization for each axle.

- Max load field for each axle (kg)

- Load difference field for each axle (%)

- Load difference error indicator for each wheel

- Numberplate/ Vehicle type - for use with numberplate recognition system and vehicles database.

Unloaded:

Loaded:

With load errors(first axle load difference error, difference more than 10%):

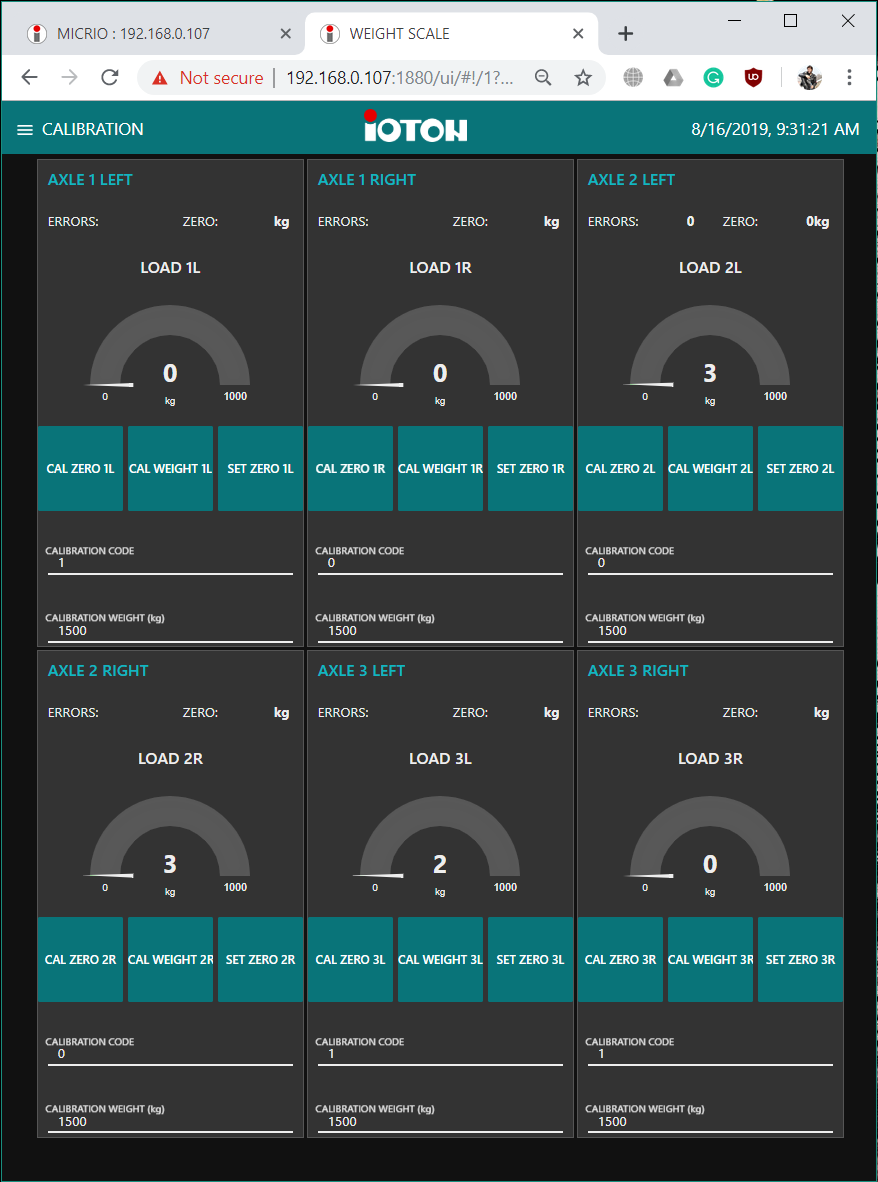

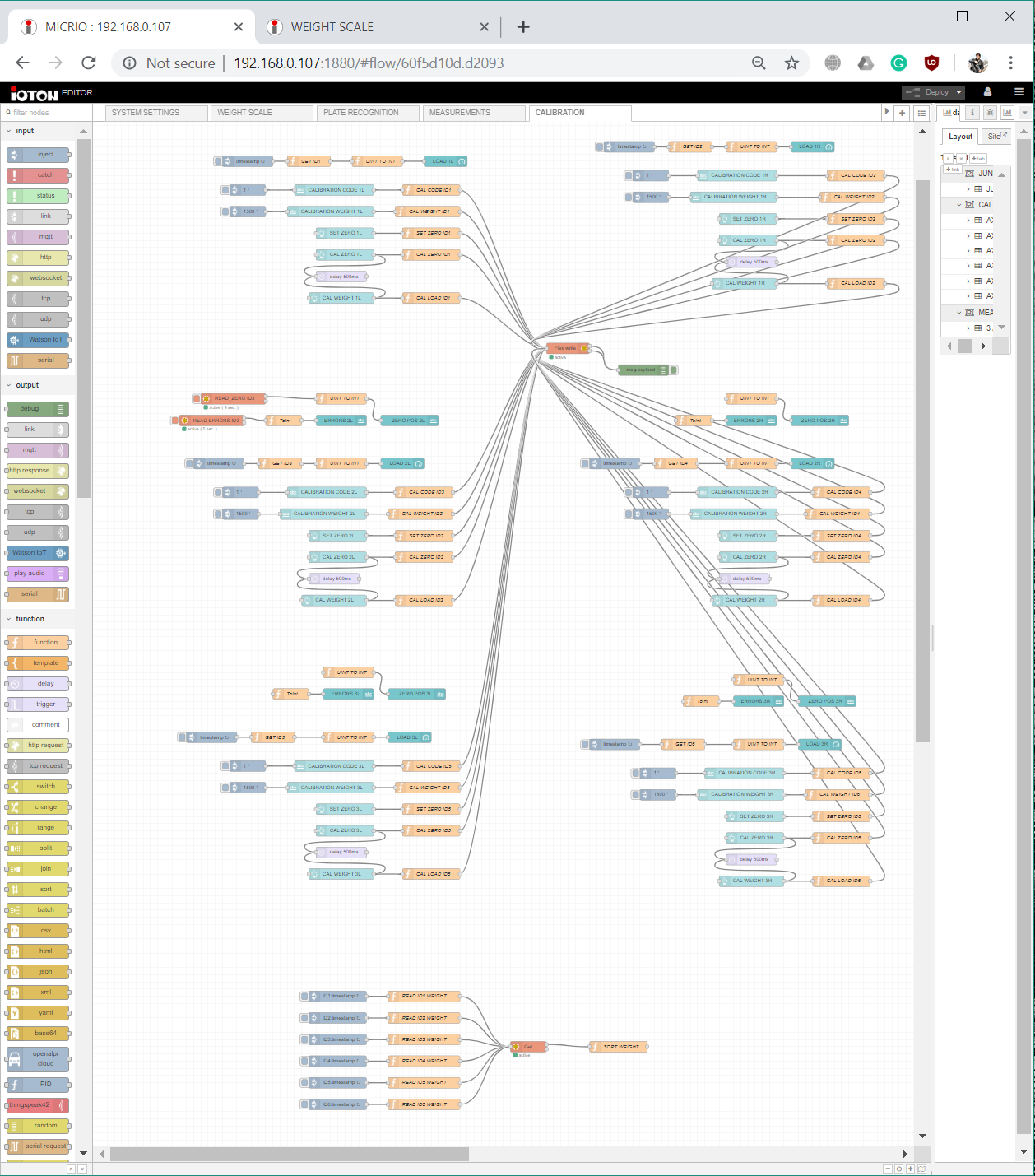

Calibration tab

For each Load cell - Modbus interface:

- CALIBRATION CODE field (cal. code is different for each Load cell - Modbus interface to protect from unexpected calibration)

- CALIBRATION WEIGHT field (you need to type calibration load weight in this field)

- Button to calibrate on zero load

- Button to calibrate on test load

- Button to set zero

- Gauge

- Sensor error indicator.

- Zero point indicator

In editor it looks like this:

Andrey V

Andrey V

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Mathematics is the good subject in which you can learn about the measurement and calculate the distance by using the formula and now I use https://edubirdie.net/howitworks to manage my college work. Students should give more attention to learn about this subject properly. It is the real subject which is interesting.

Are you sure? yes | no