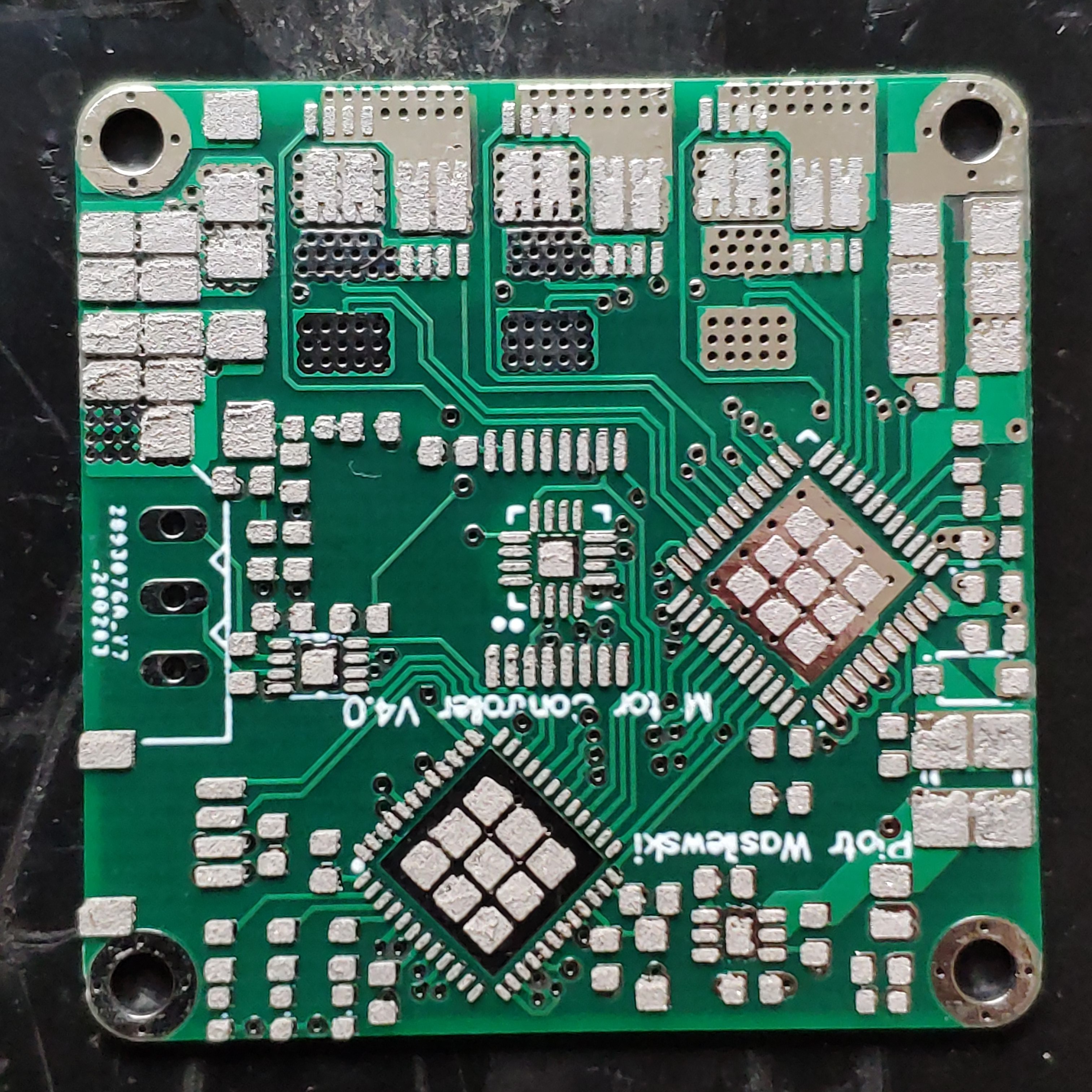

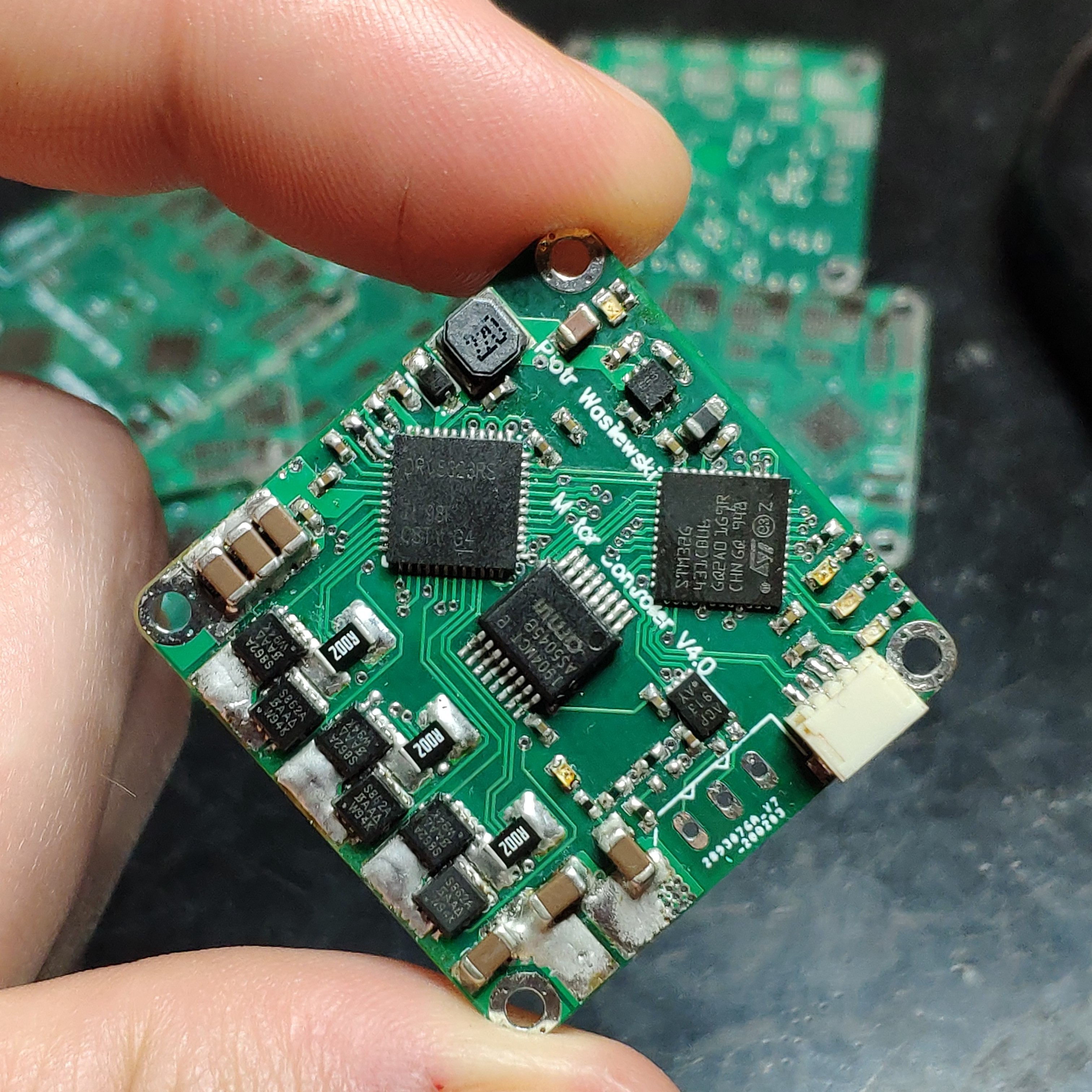

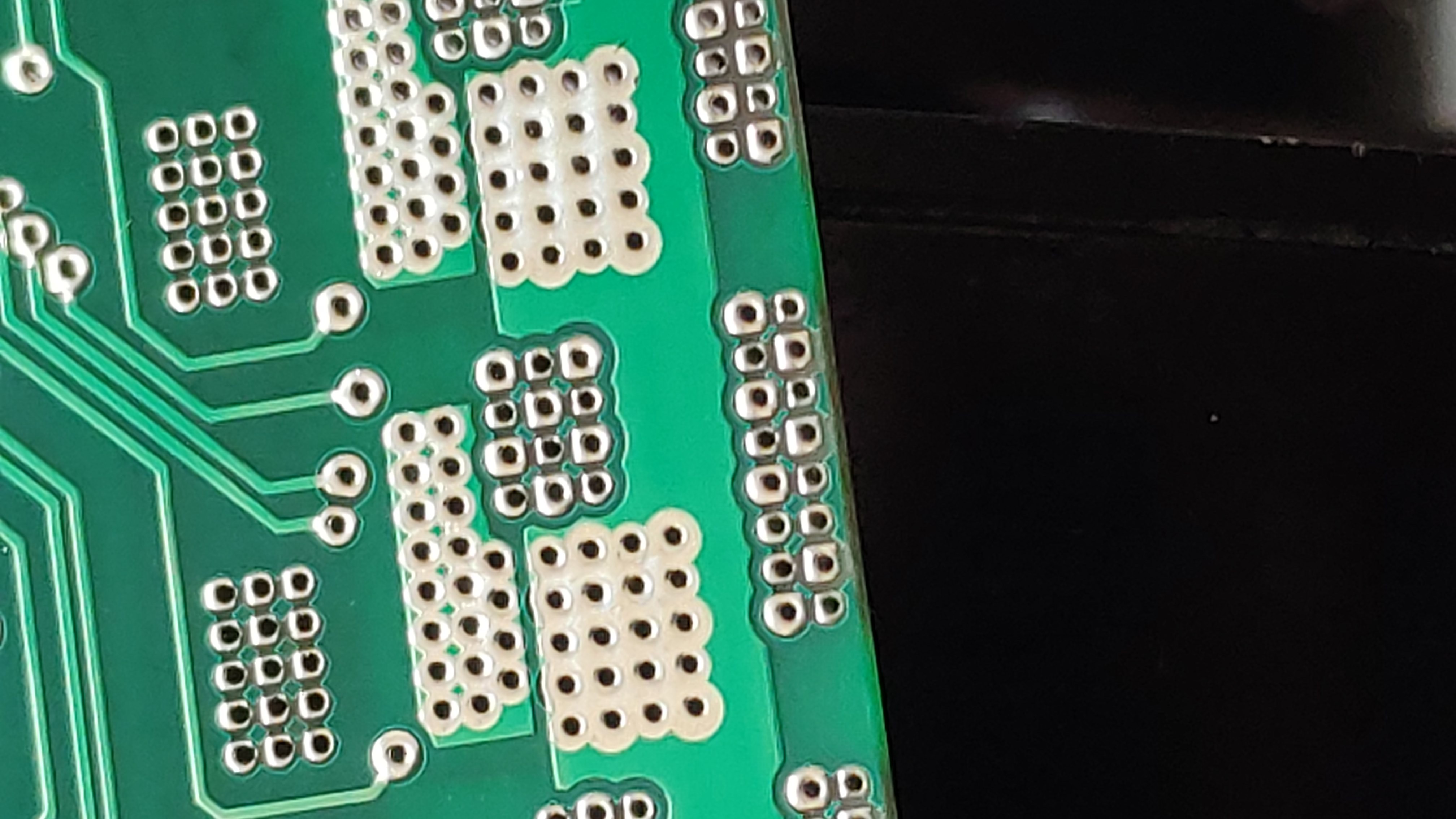

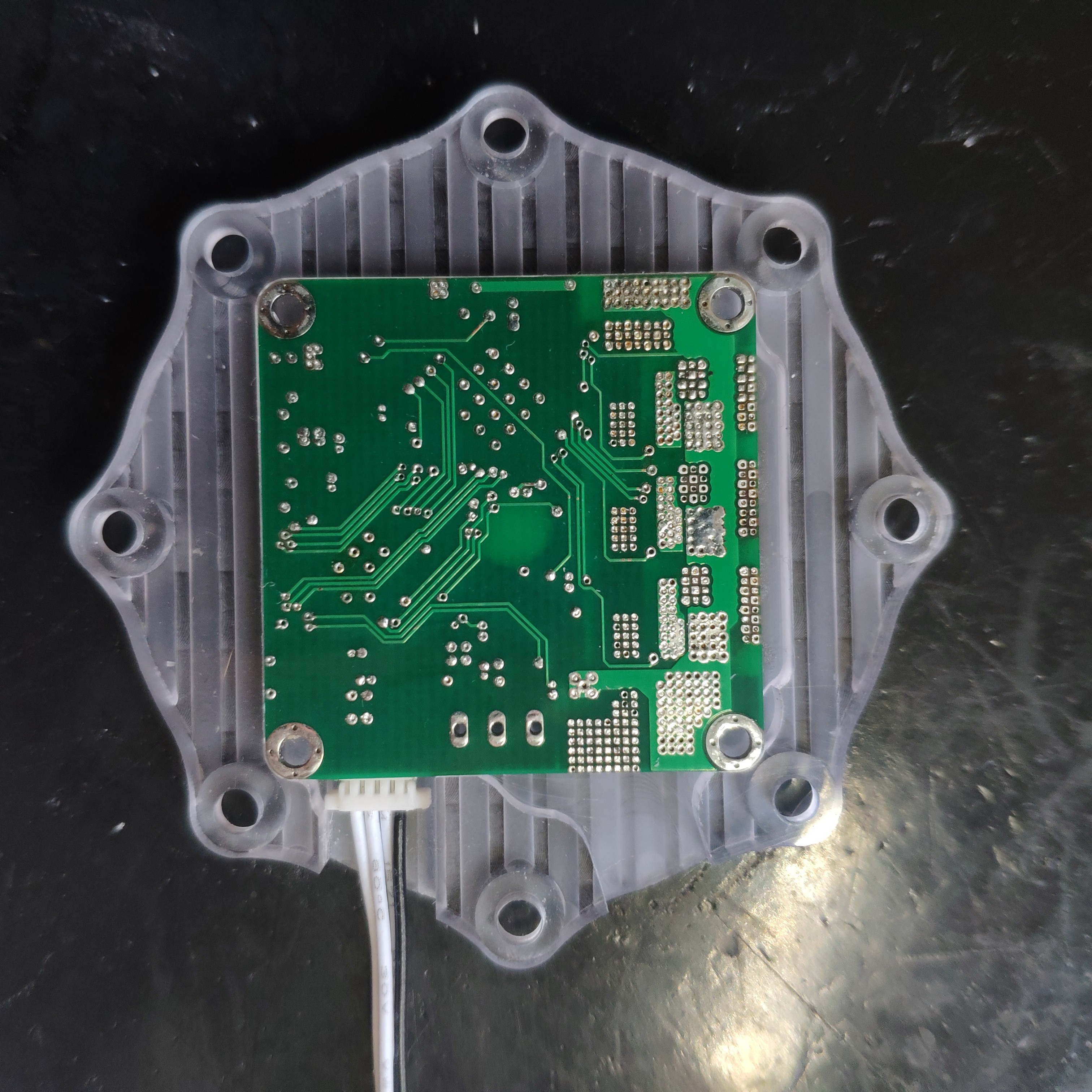

Finally the PCBs have arrived. I guess I imagined them a bit bigger, as I was surprised by how small they really are. The outline is just 33x33mm, so I will be able to fit it behind almost any of my smaller BLDC motors. Since I last wrote I've been working on the software of the controller. For now I'm able to perform some basic operations on the motor as spinning in the non-feedback mode (voltage mode) or current feedback mode. The controller is also able to do a magnet offset calibration as well as encoder non linearity calibration and save the calibration lookup table in flash memory. Though everything seems to work fine at first glance, I still get annoyed by the irritating sound coming from the motor. I even wrote a post on the TI forum (https://e2e.ti.com/support/motor-drivers/f/38/p/921831/3412724#3412724) but the issue is still unresolved. I will investigate it further someday, however right now I'm out of ideas.

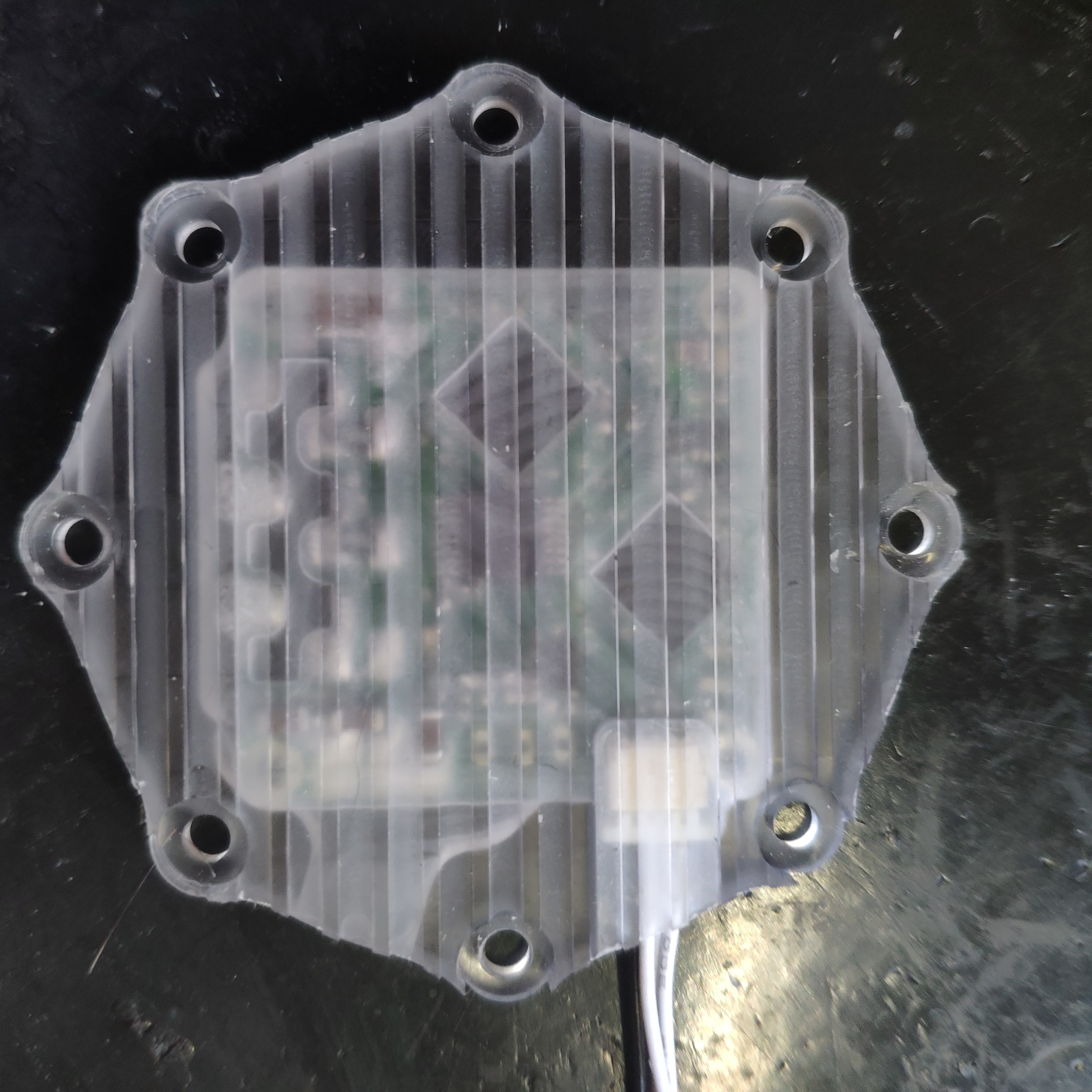

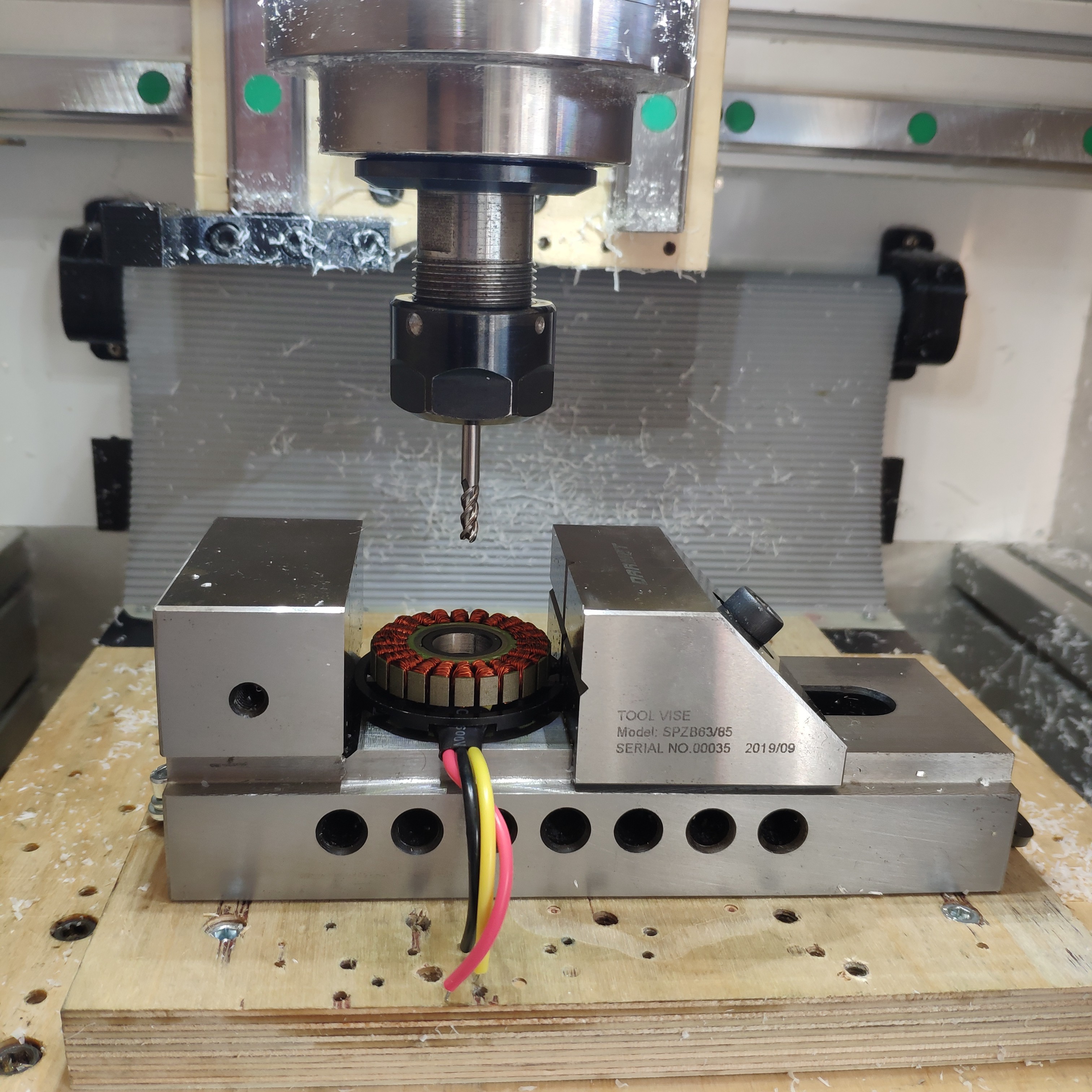

Right now I'm working on a mechanical casing and planetary gear for the motor module. I managed to mill some prototype parts and it looks promising, however I'll tell more when the first prototype is ready. The biggest issue for now is the backlash of the planetary gear extracted from cordless drill. On a 3d printed prototype, I get roughly 1.5* of backlash when the motor shaft is stalled. I believe I'll be able to take it down to 1* or less with a bit of precise machining. Even though it seems much when I remember that triple stage planetary reducer for a drill cost me about 5$ each I guess it is a decent outcome anyway. Below a few random photos from prototyping process:

When I'm ready with a fully machined prototype I'll write an update ;)

Peter Wasilewski

Peter Wasilewski

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Awesome! Do you have any plans to sell these controllers once the design is finalized? I think there's a pretty big demand for such a thing.

What brand/model of motor is that you're butchering? Looks nicely proportioned.

As for the motor noise, maybe mechanical resonance of the rotor? That random delay in the switching should be producing all sorts of frequencies, so the motor may be amplifying one of them. Try setting the PWM frequency to match it and see if you get louder noise than with any other PWM frequency.

Are you sure? yes | no

Hi!

For now I wasn't planning to sell any of these. Maybe someday when the software part is fully functional. I do not want to sell anything buggy or underdeveloped ;)

The motor is chineese QM5006 motor. It's cheap and relatively low quality (the windings are wound in a sloppy way, the rotor has a bit of play on the bearings etc.) but with a bit of machining I believe I can make it work. I haven't measured the torque capability yet, but I expect a torque constant of 0.028Nm/A (It was estimated by measuring back EMF while rotating the shaft).

Regarding the noise - it definitely comes from vibrating coils. That's for sure. However the question is where is the delay coming from - the input PWM's are switched in exact same moments but the outputs get these occasional delays between each other.

Are you sure? yes | no