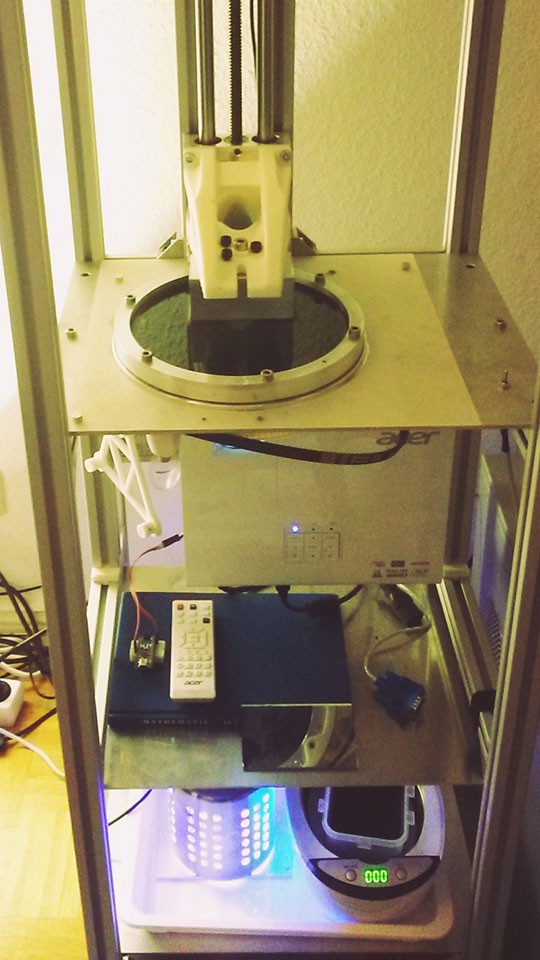

In the third Iteration i replaces the rotating VAT with a FEP flexvat, which worked perfectly. The biggest problem is sagging of the FEP film, so I developed a n acrylic bed system which would keep the film straight, while letting air flow through the bottom, so the FEP was flexible enough to peel as the parts are pulled up.

Details on VAT construction will follow.

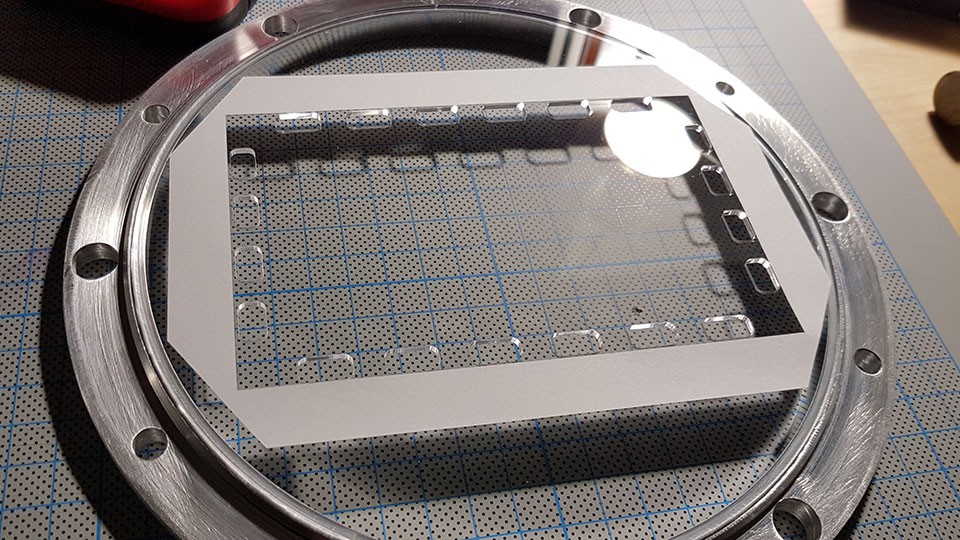

Clear Acrylic bottom with air holes to prevent the FEP from sticking.

Paper spacer for tiny gap of approx 80micron to bottom. This does not noticeably change part geometry, while preventing sticking of FEP to acrylic.

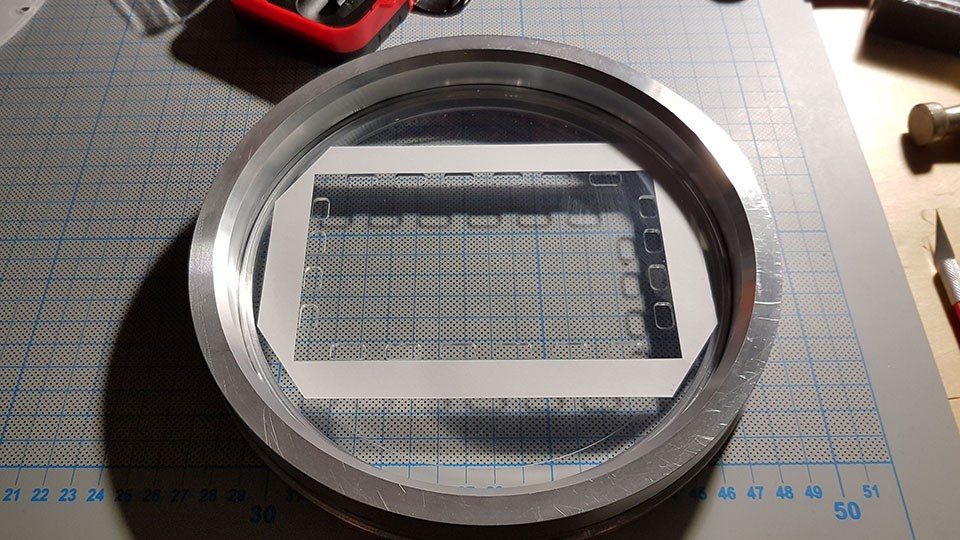

fully assembled VAT

Photo showing new VAT prototype in action

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.