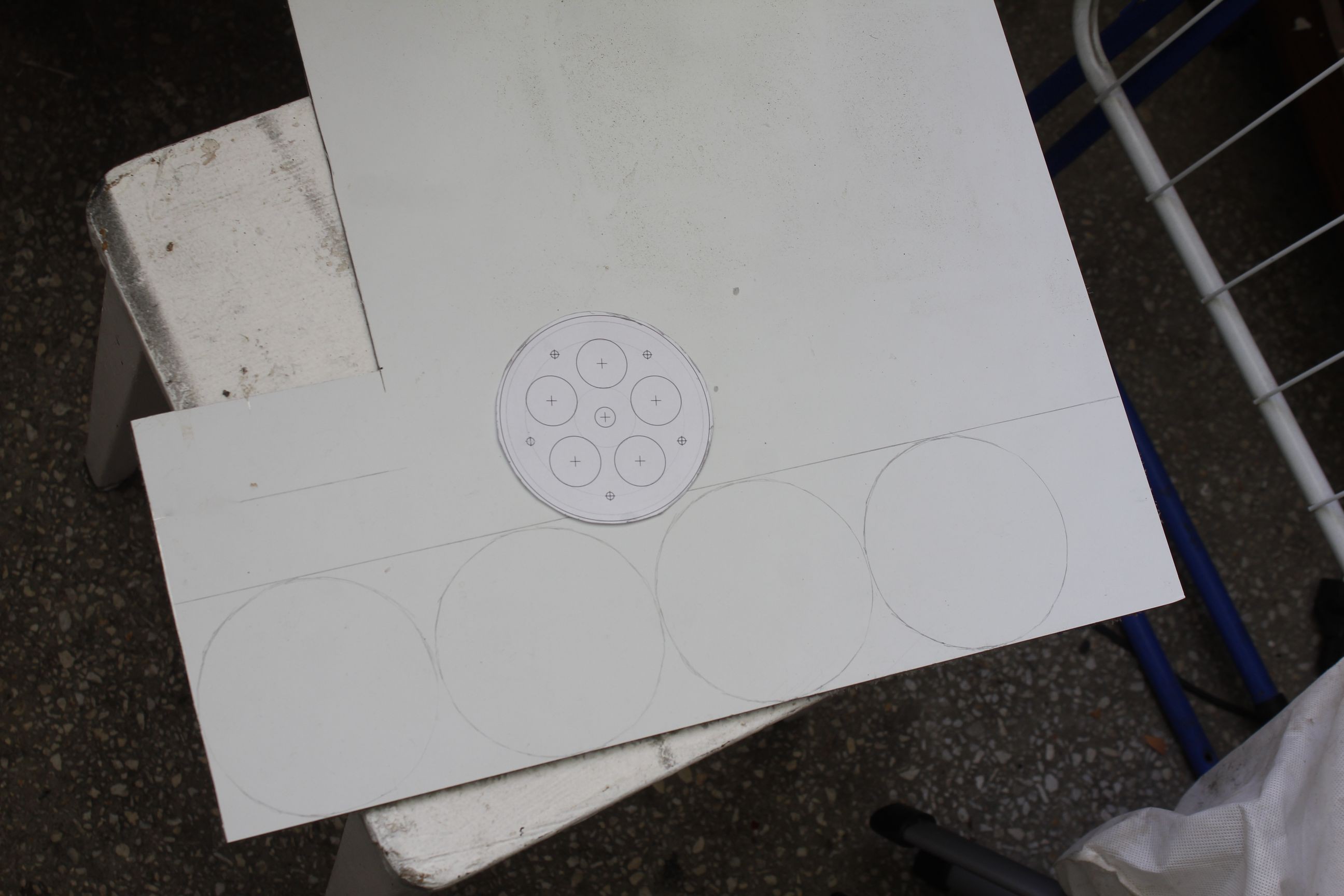

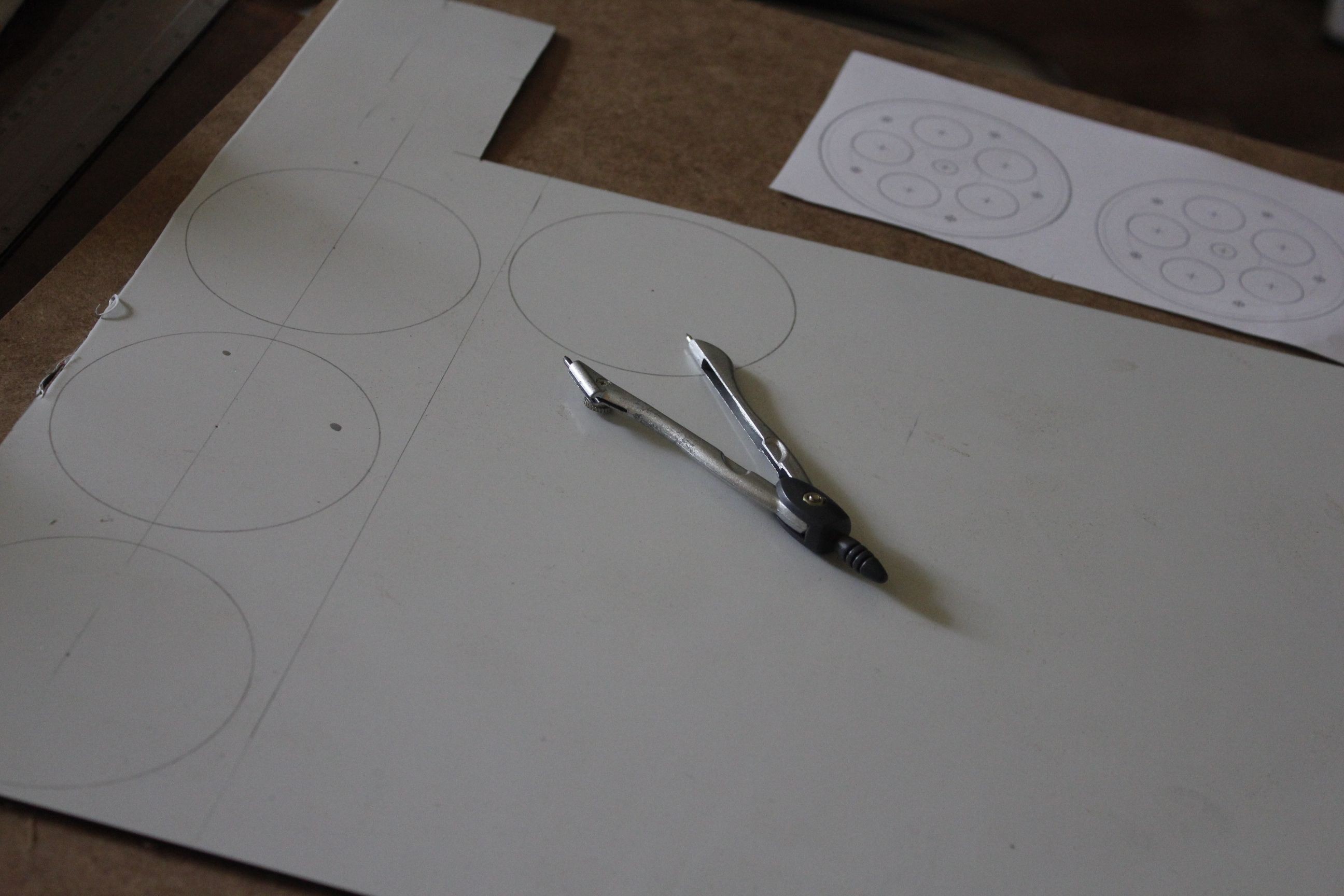

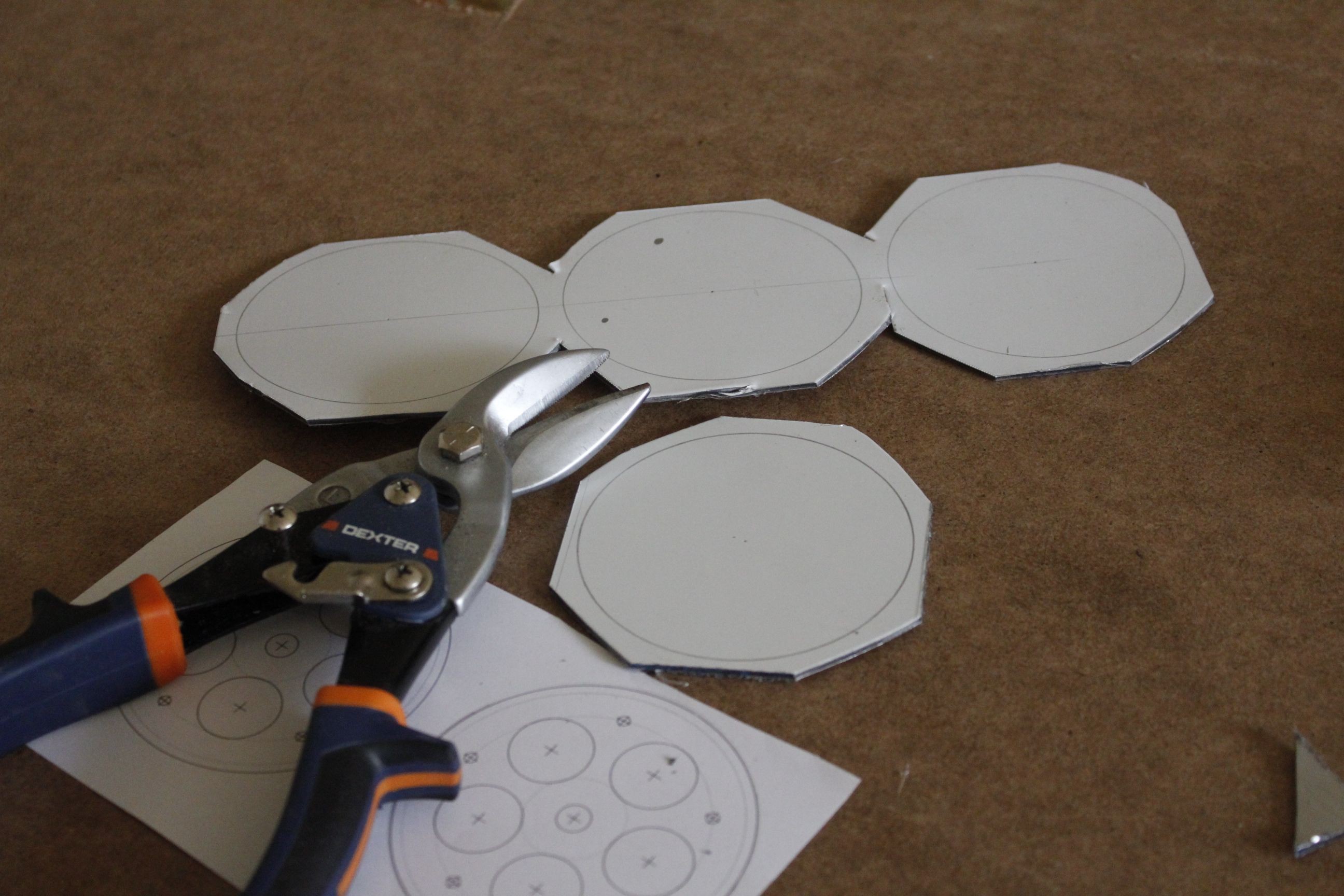

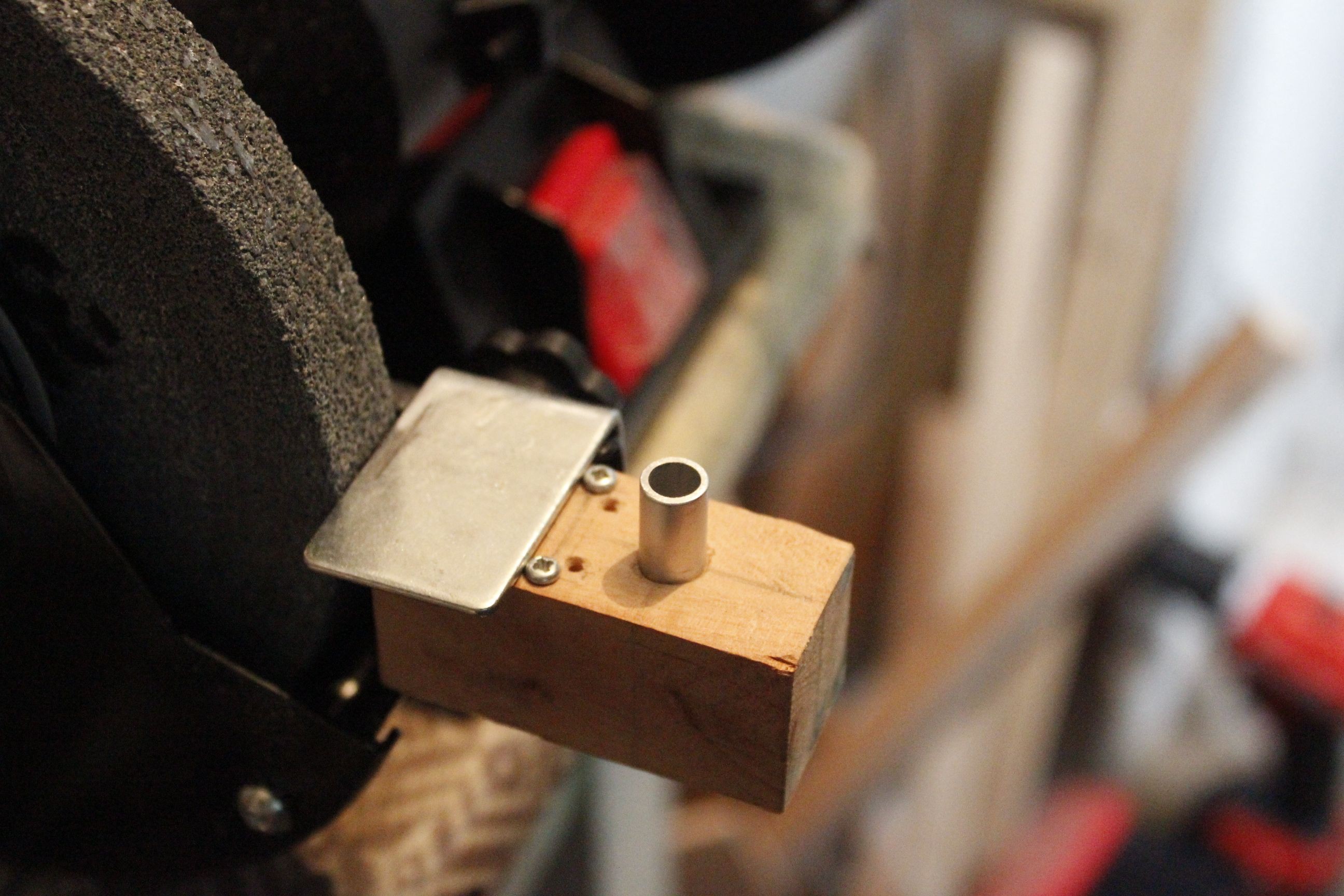

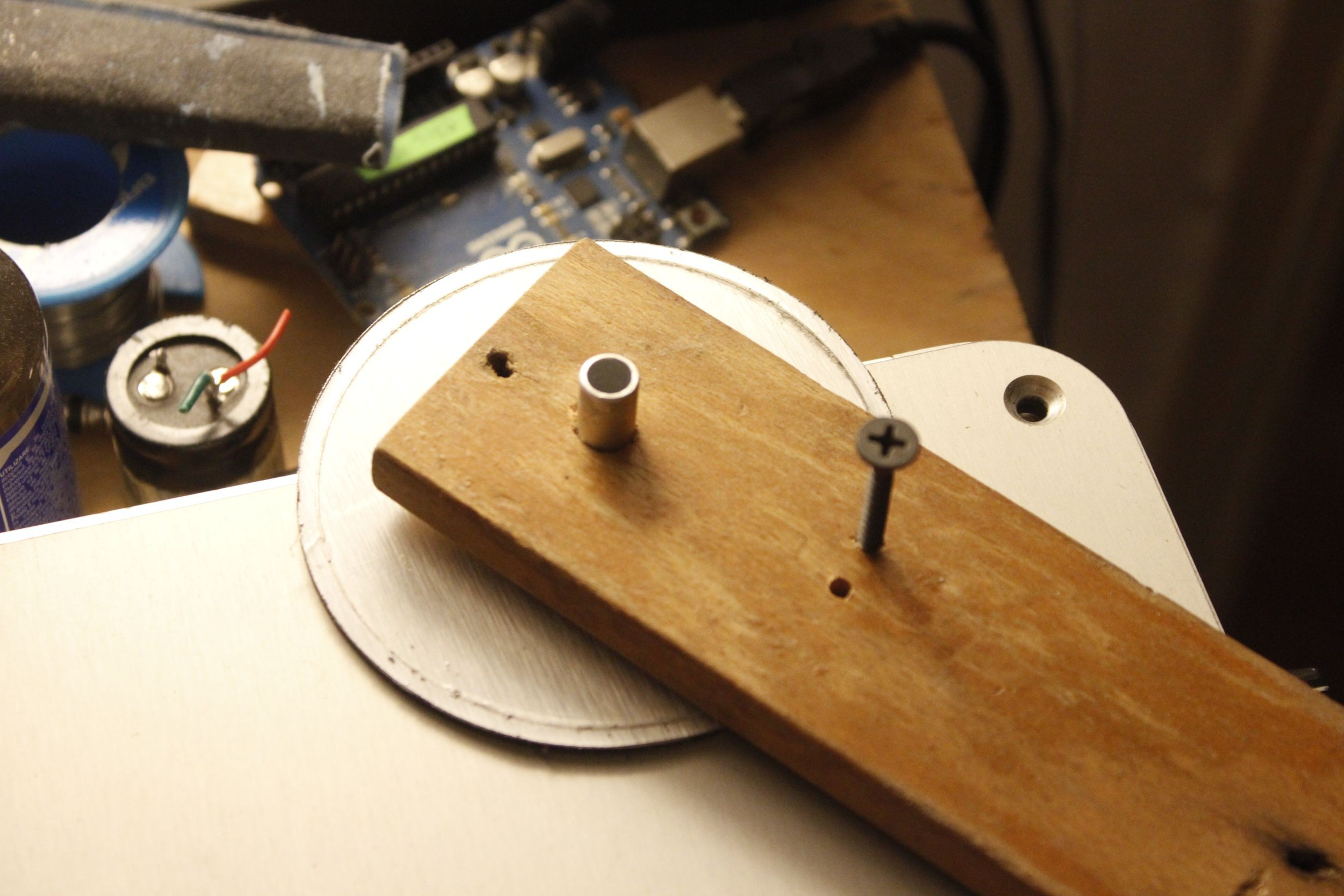

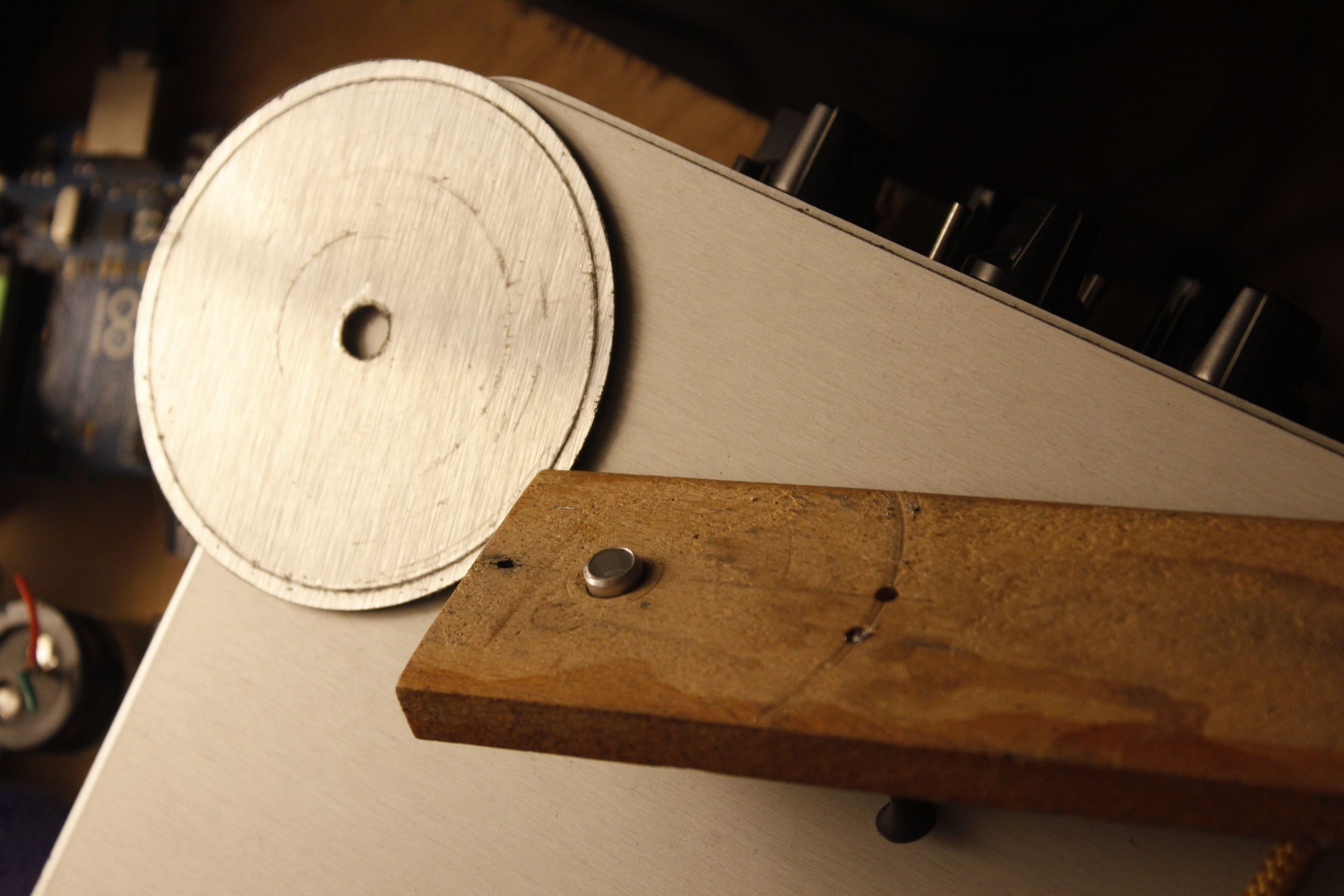

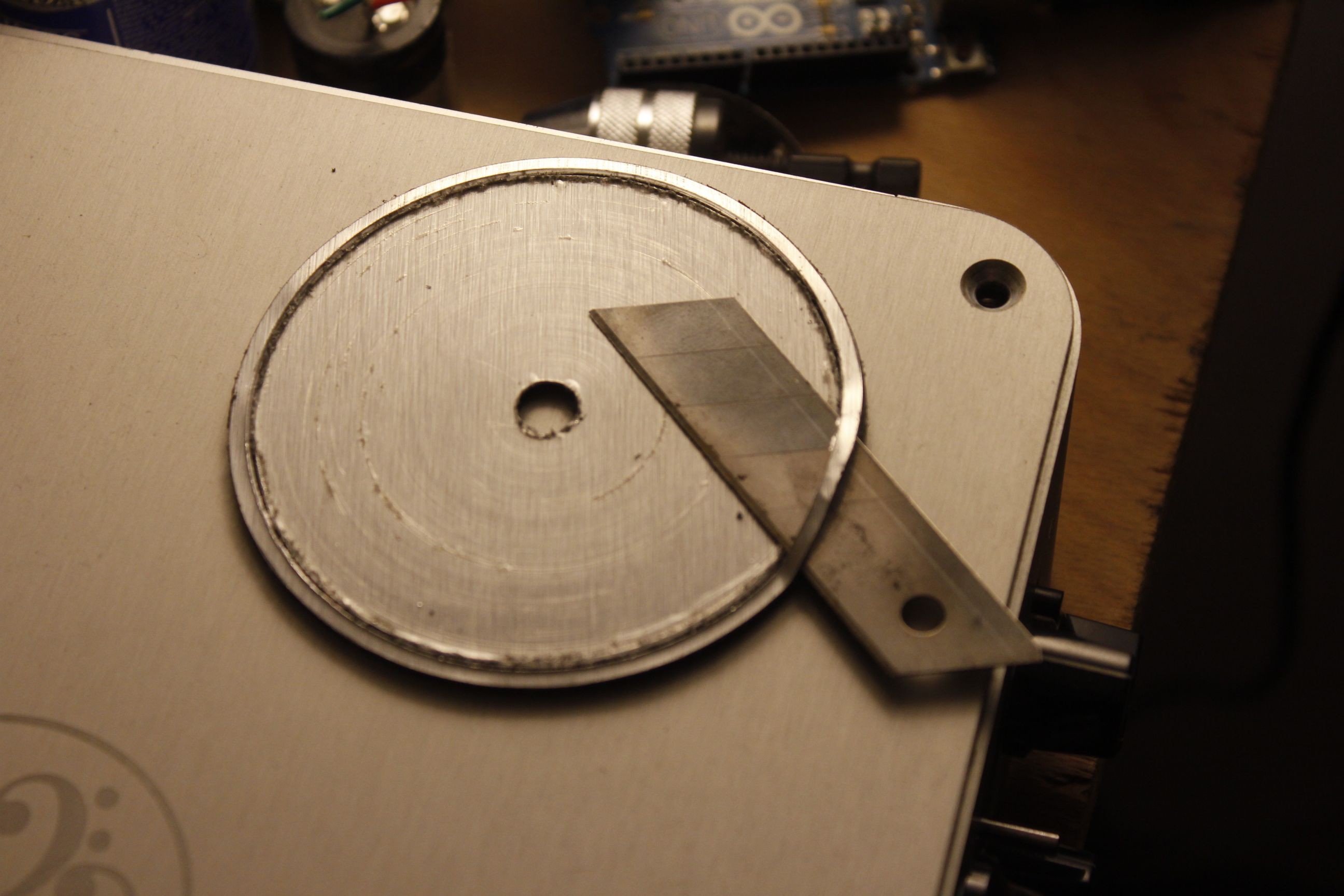

Fabrication started with the cams, specifically the circular, bowstring ones. Each is constructed from a disc of 4 mm MDF sandwiched between two 2 mm Dibond type aluminium-plastic laminate sheet discs. These were cut with sheet metal scissors and ground using a small jig to ensure circularity. Space for the string tracks was first scraped using a wood screw and then filed to shape. Weight relief holes were drilled, then pop rivets and contact adhesive were used for final assembly.

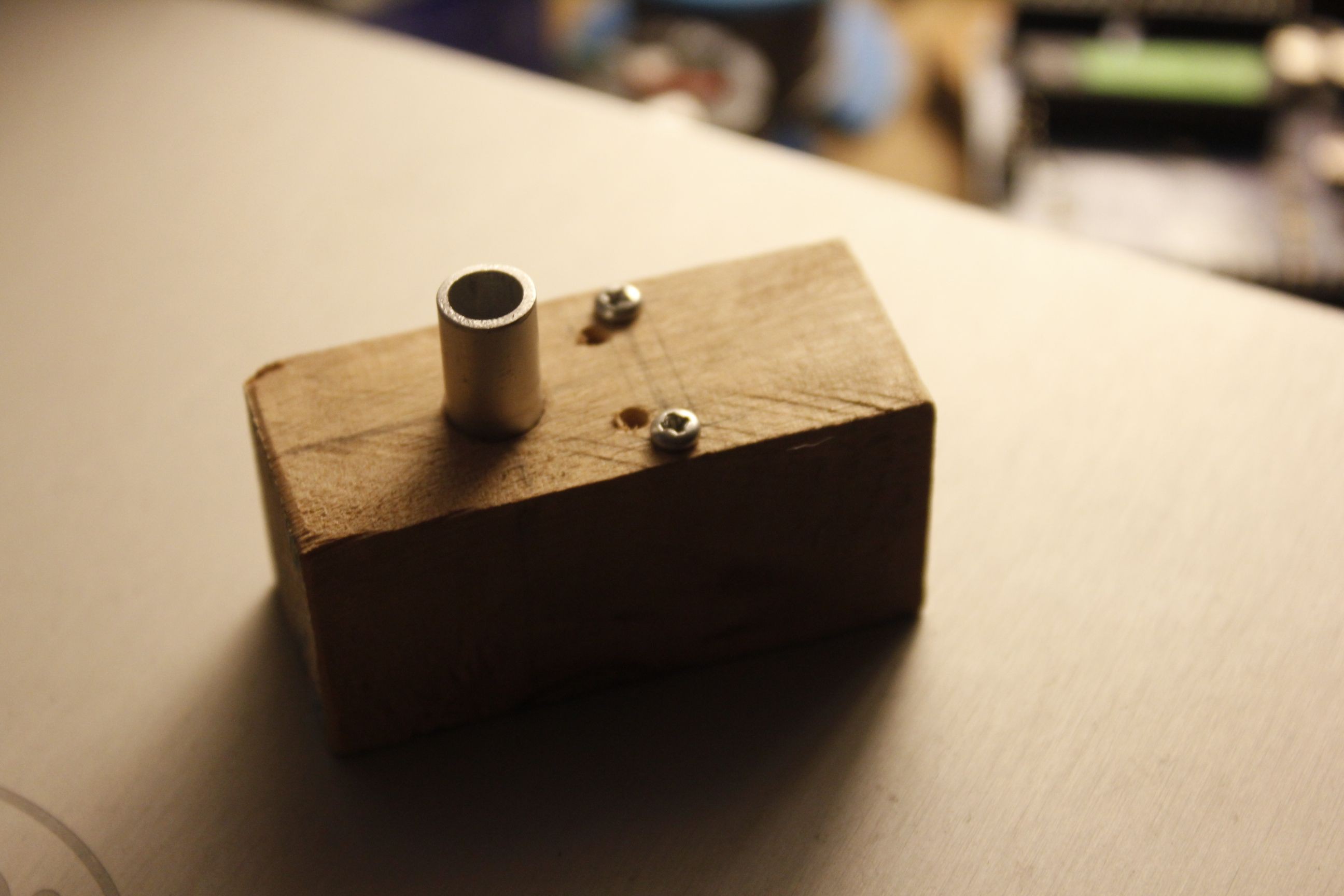

Next the central spiral cam was cut from a piece of hardwood, then drilled and cut using a combination of sawing, bench grinding and hand filing. The cams are then connected through three long screws, after the cable is secured and some paint is applied.

FiveseveN

FiveseveN

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.