Many years ago, I took up playing the English concertina because I wanted to be able to play sea shanties. I quickly learned that the concertina is quite a versatile instrument with a much richer history than I had imagined. First, it was invented by a hacker, Sir Charles Wheatstone, way back in 1829. (Sir Charles did a lot of interesting stuff, including telegraphy, crypto, the stereoscope and developing the Wheatstone bridge.) Second, it was originally used for playing virtuoso solos and as a chamber music instrument with an orchestra before it was widely used for popular music in the late 1800s and then again during the folk music revival in the 1960s. But, whatever. I learned to play the concertina, not the piano.

Since I can already play one, when I decided I'd like something to control a synthesizer, the obvious form factor was the concertina. Trouble is, there are none very few around. If I wanted one, I'd have to design and build it.

The result is what you see here. It has 56 buttons, 28 on each side. The buttons operate Cherry MX switches (the non-clicky kind) that I've modified by adding an internal diode to each one. They are organized as one big 4 x 14 matrix that I can scan with a microcontroller and a pair of shift registers. The microcontroller is an Adafruit Bluefeather 32u4 which comes with an on-board Bluetooth LE radio and, to make life super simple, a MIDI-over-Bluetooth-LE library. To set the MIDI "Expression" (volume), there's a differential pressure sensor that measures the pressure difference between inside and outside of the bellows.

The bulk of the physical structure is made from 3mm Baltic birch plywood. I designed the parts in Adobe Illustrator and laser cut them. The fancy wood on the outside is eighth-inch maple and maple plywood that has been engraved using the laser cutter. The buttons are made of Delrin rods, so they slip nicely when pushed. The bellows is made from pasteboard, thin type 10 Tyvek, and ripstop nylon. The three layers were laser-cut and then glued together with PVA glue.

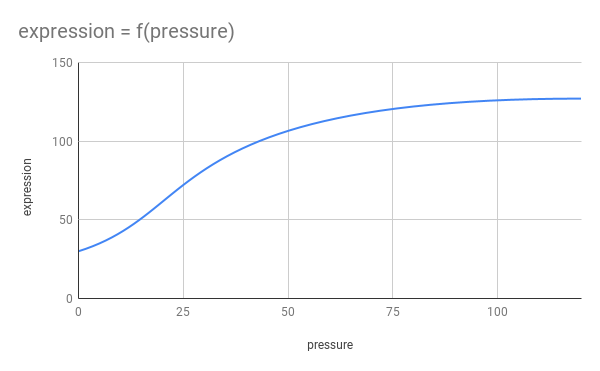

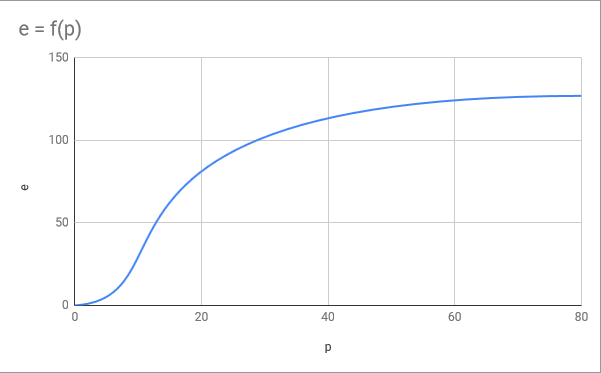

At this point the concertina works quite well (video on Vimeo) -- it's certainly playable, and the feel of the buttons is good. The original bellows was too springy, because the cardboard bumped into itself at the peaks and and was stretched at the valleys when completely compressed, but I redesigned the whole thing and it now works well. Initially, I wasn't keen on the red ripstop I used. I thought something a bit more toned down would look better, but the look has grown on me. The final adjustment I made was to the transfer function that maps bellows pressure to MIDI Expression. It surprised me how much subtle changes to it changed the feel of the instrument.

Dave Ehnebuske

Dave Ehnebuske

Hi Dave, great project. I've been considering something like this for some time. I think with the latest technologies 3D Printing and single board low cost computers for synthesis, it could become a reality. I like the idea of using Cherry MX switches. Do you have a drawing of the front panel of the concertina, if not maybe the pitch between switches horizontally and vertically. Many thanks.