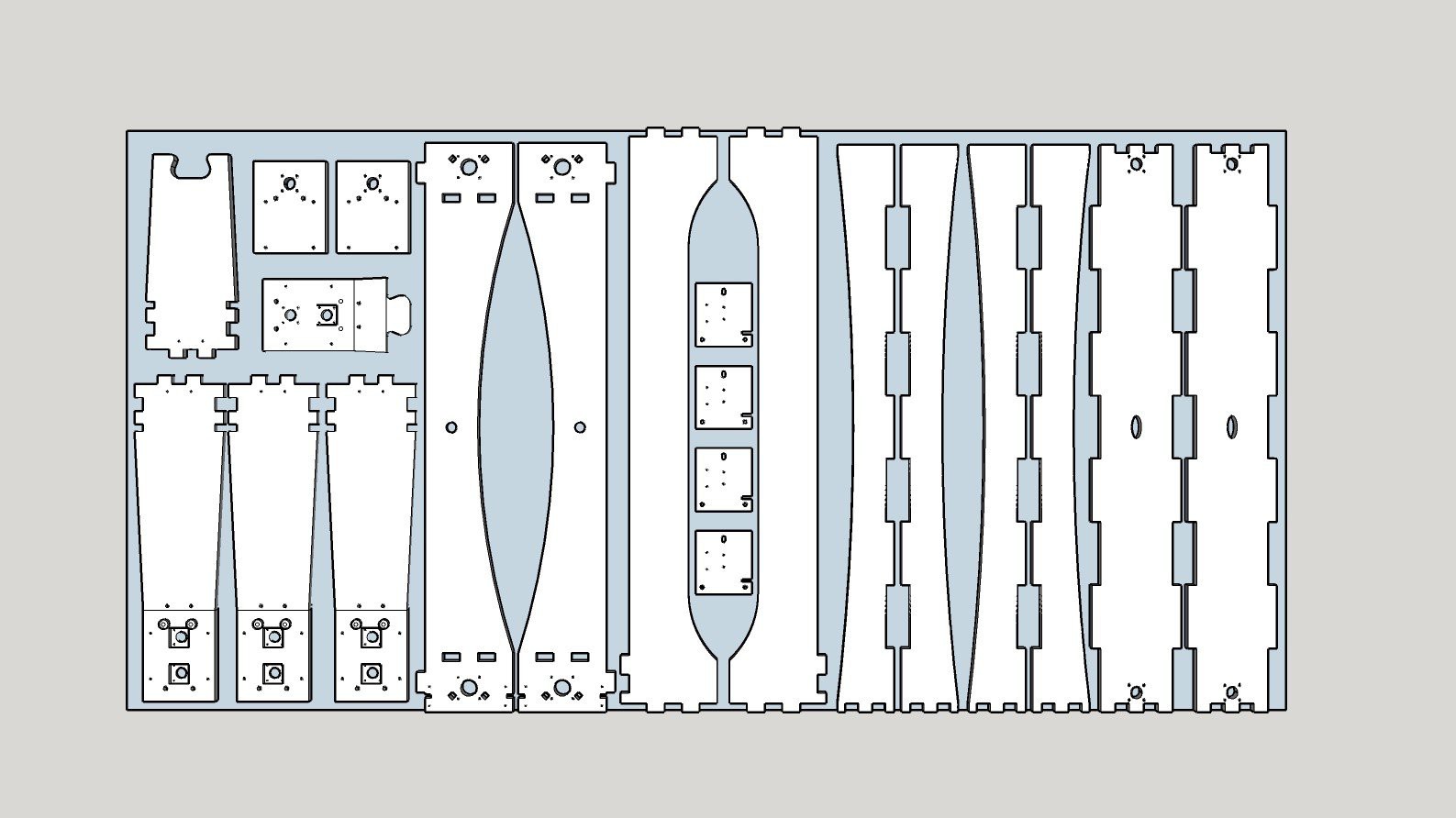

One thing is clear after the first protype failed half way. No more manual cutting of parts. So I redesigned the model of the prototype again such that almost all of it can be cut using a single 4x8 sheet of sheet material ( MDF in my case). I outsourced the job of CNC cutting to a vendor and had the new parts to assemble within a day.

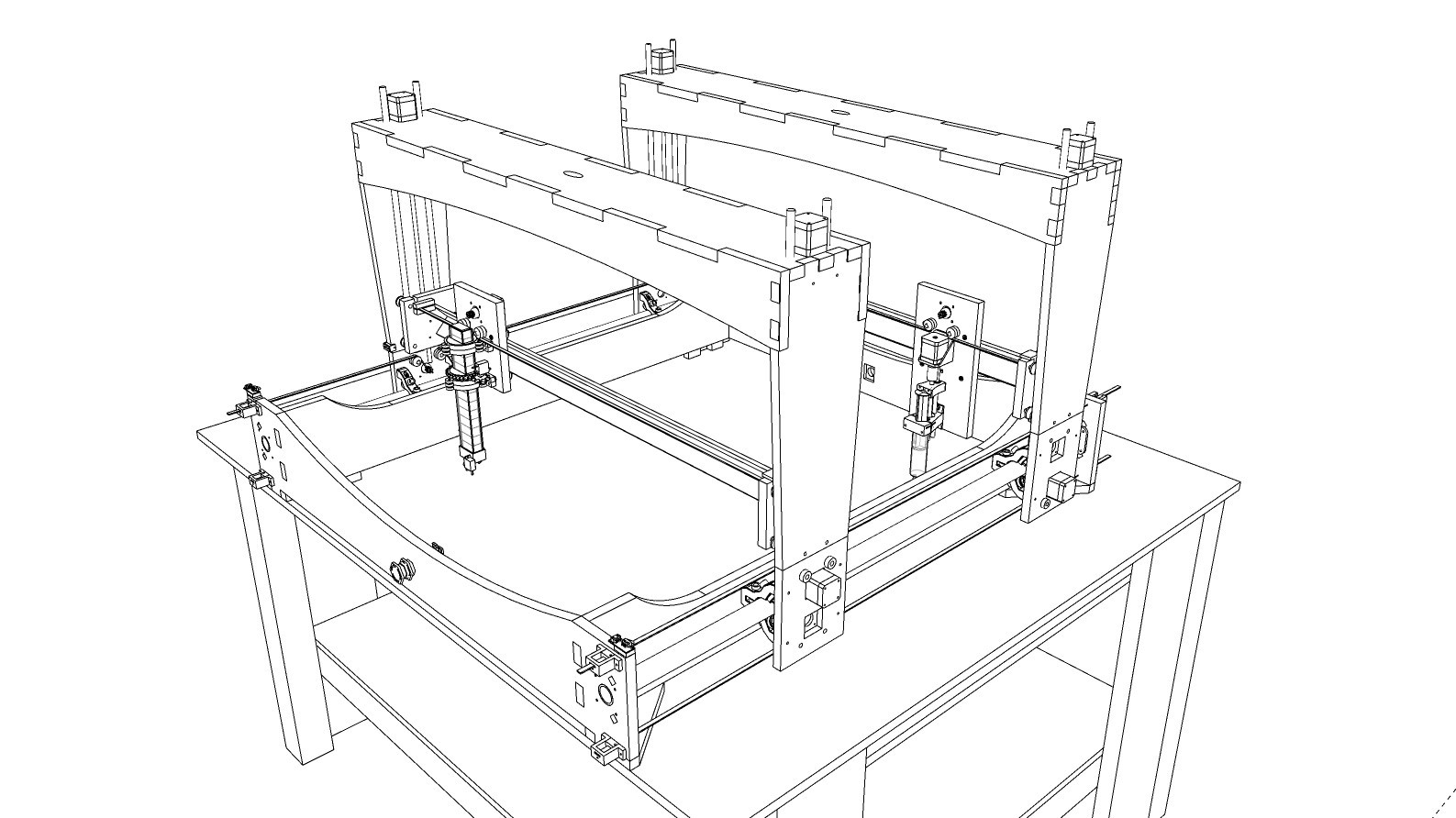

It took another one day to bang together all the parts in place for my next prototpe.

There was a night and day difference between this and my first prototype. The frame was really solid for its intended purpose and the gantries rolled smoothly over, the rails.

Nishant Agarwal

Nishant Agarwal

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.