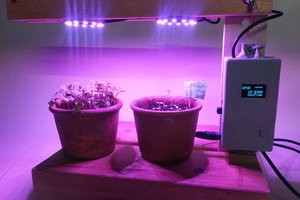

The idea behind this project is to create a product that can be made entirely at the DesignLab, using the equipment available at hand. It should be relatively easy to put together, not (that much) labor intensive, and interdisciplinary.

For this project I have the help of my amazing team members: Voja Antonic, Bruce Dominguez and Erika Earl.

Giovanni

Giovanni

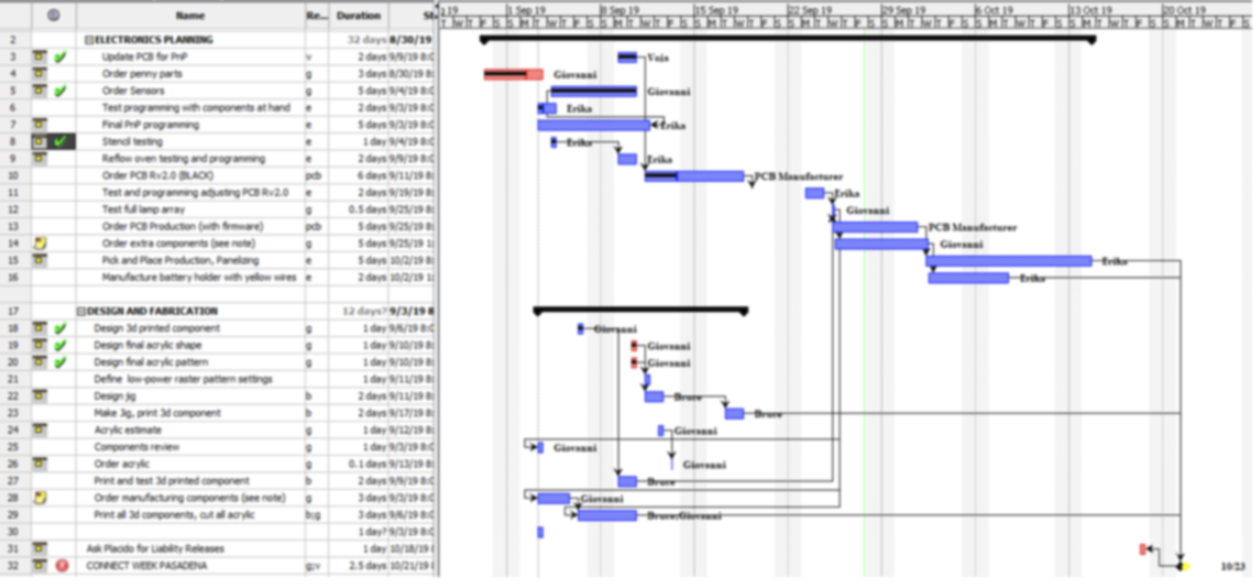

One of the tools that I use a lot is a Project Management application called Project Libre (

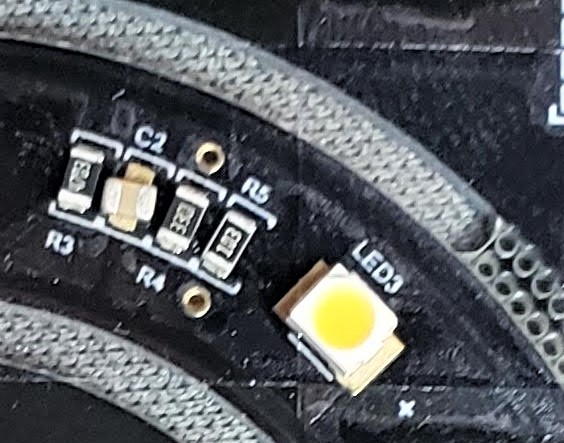

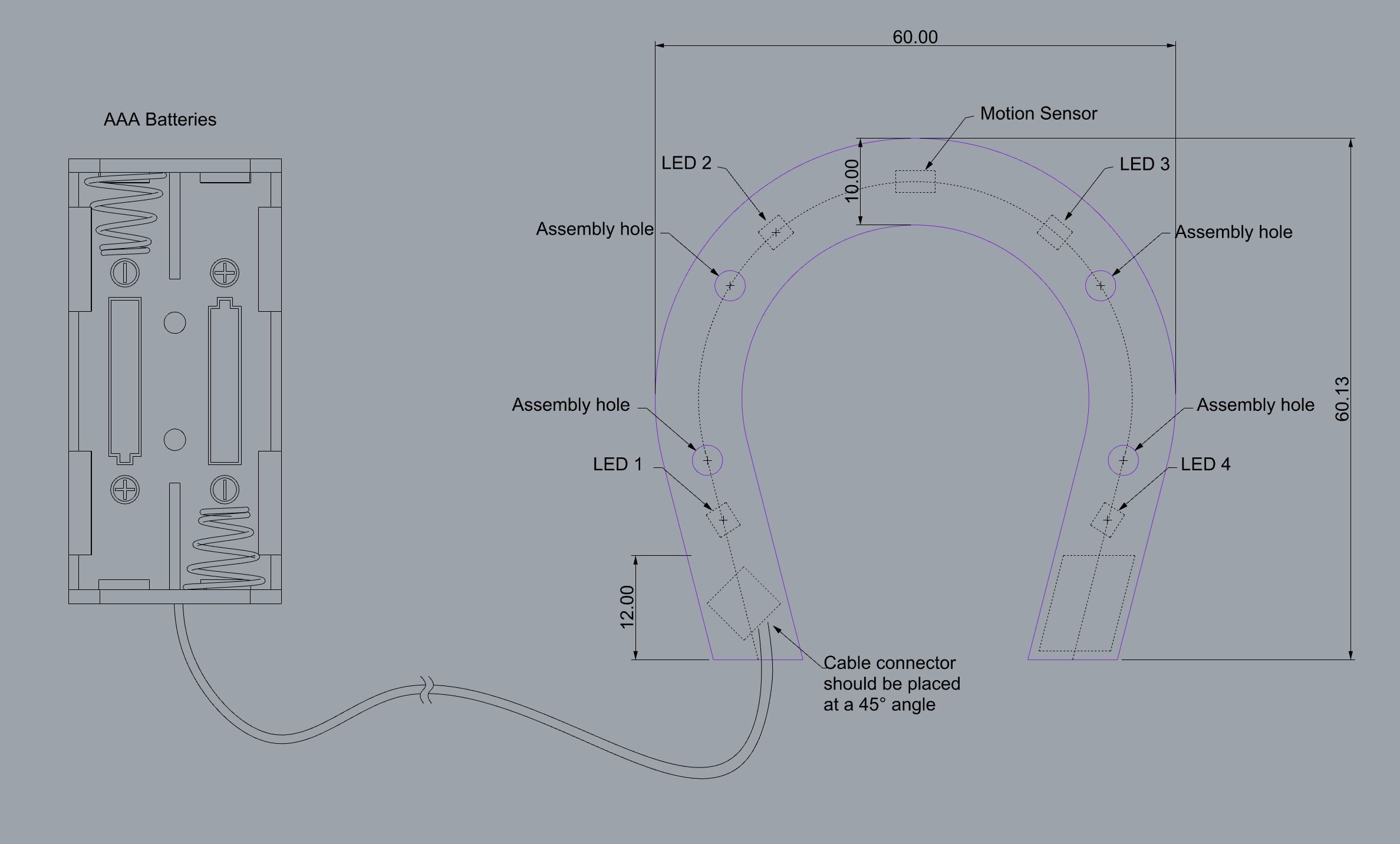

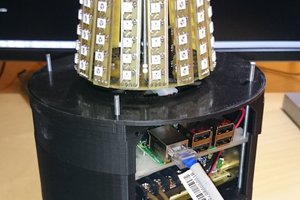

One of the tools that I use a lot is a Project Management application called Project Libre ( We are using a 2-component motion sensor. It is actually just one sensor but it needs an LED next to it. Voja managed to put a shrink-wrap sleeve on it for prototyping but we have to plan something for production. Production that is, a few hundred pieces. It does not make sense to make a plastic injection mold for this, so we will go full on 3D printing.

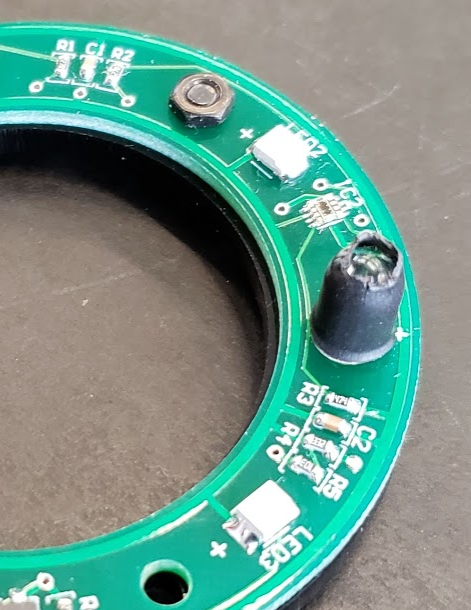

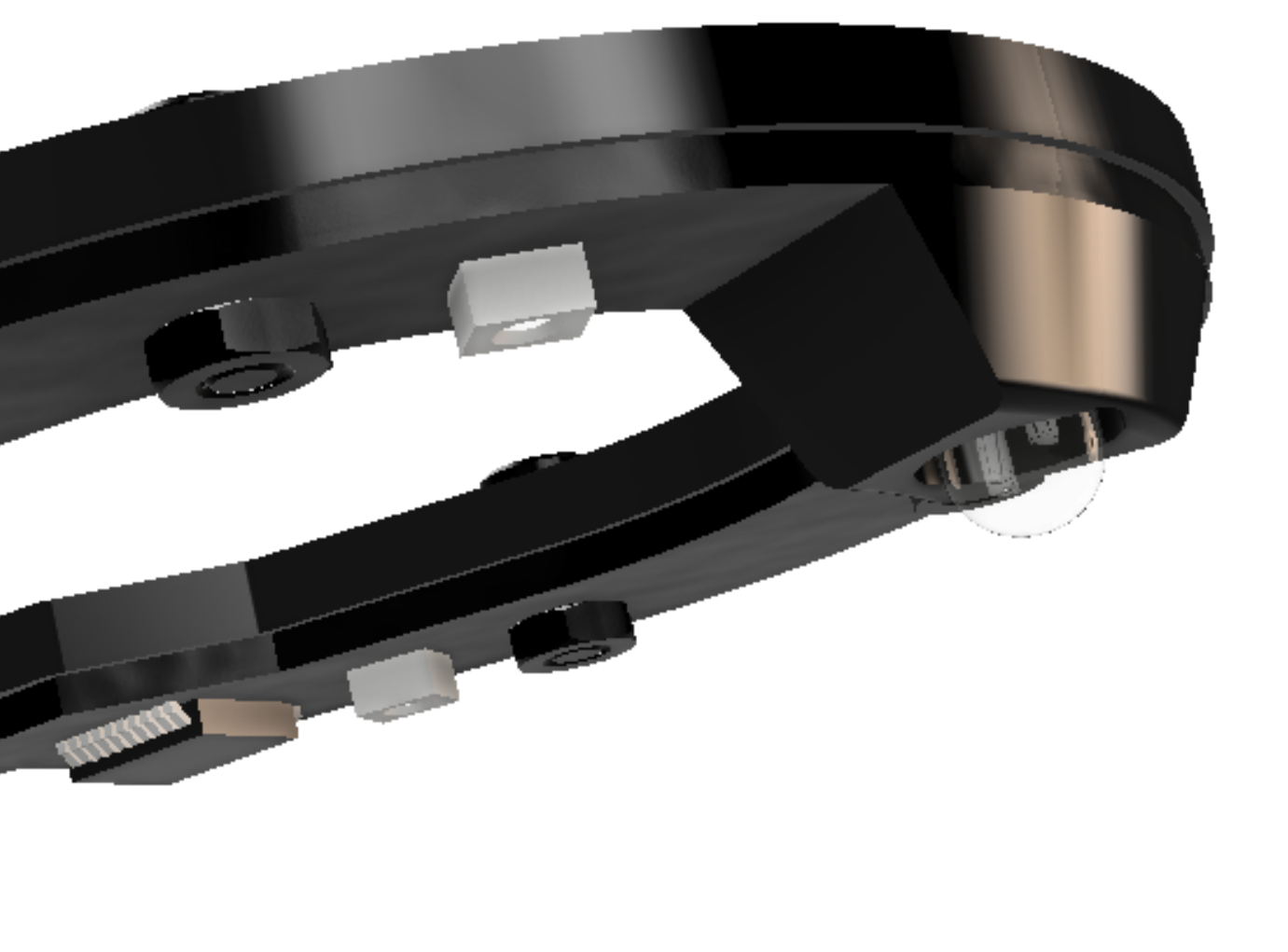

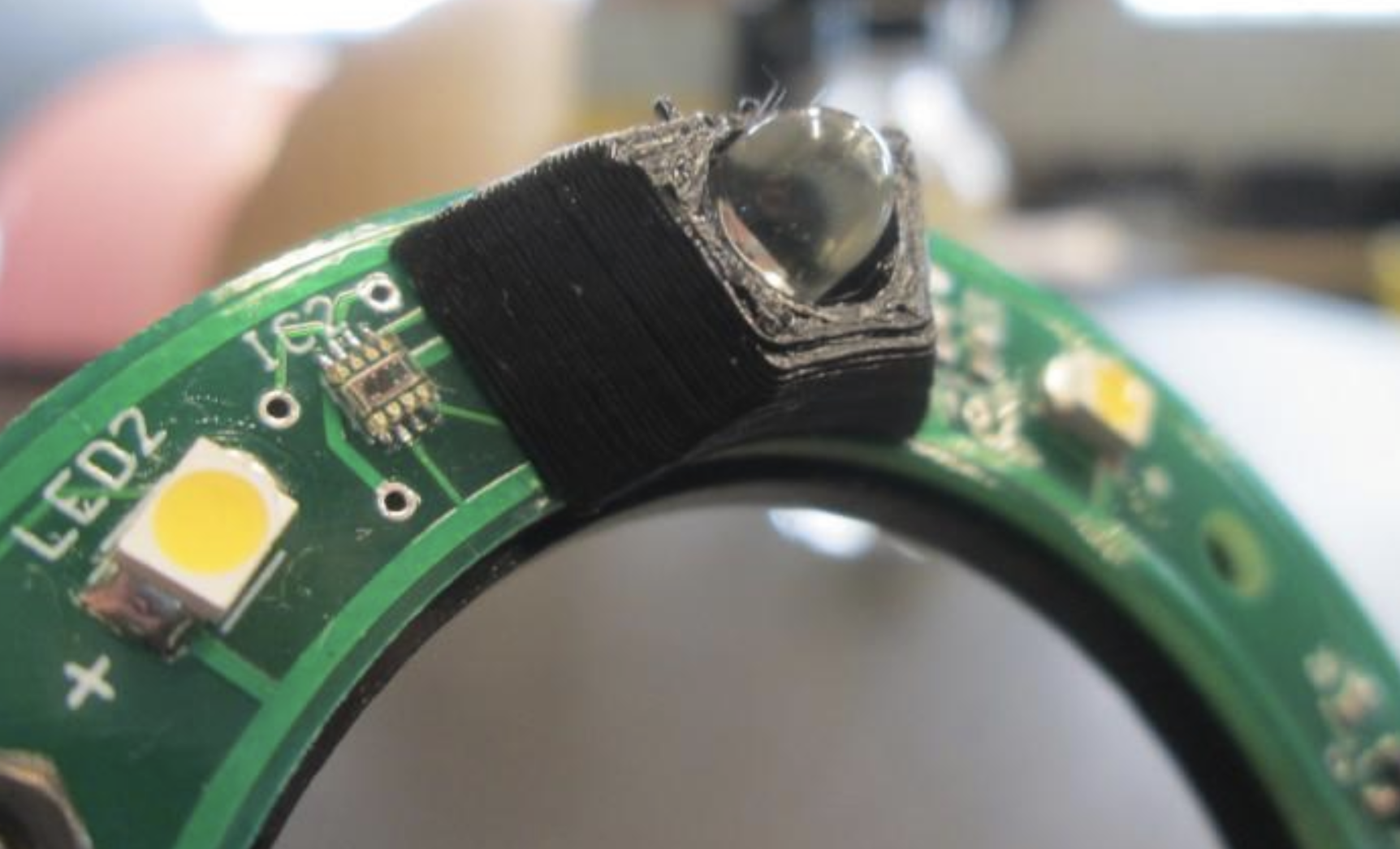

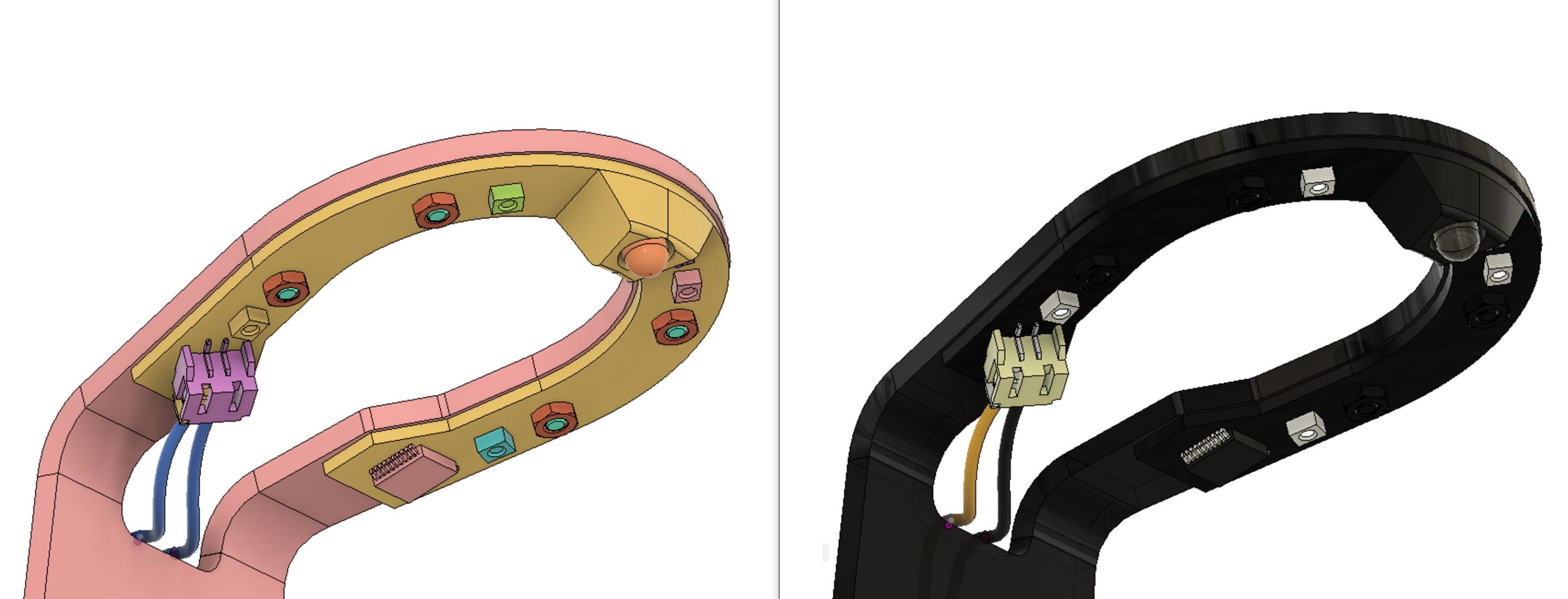

We are using a 2-component motion sensor. It is actually just one sensor but it needs an LED next to it. Voja managed to put a shrink-wrap sleeve on it for prototyping but we have to plan something for production. Production that is, a few hundred pieces. It does not make sense to make a plastic injection mold for this, so we will go full on 3D printing.

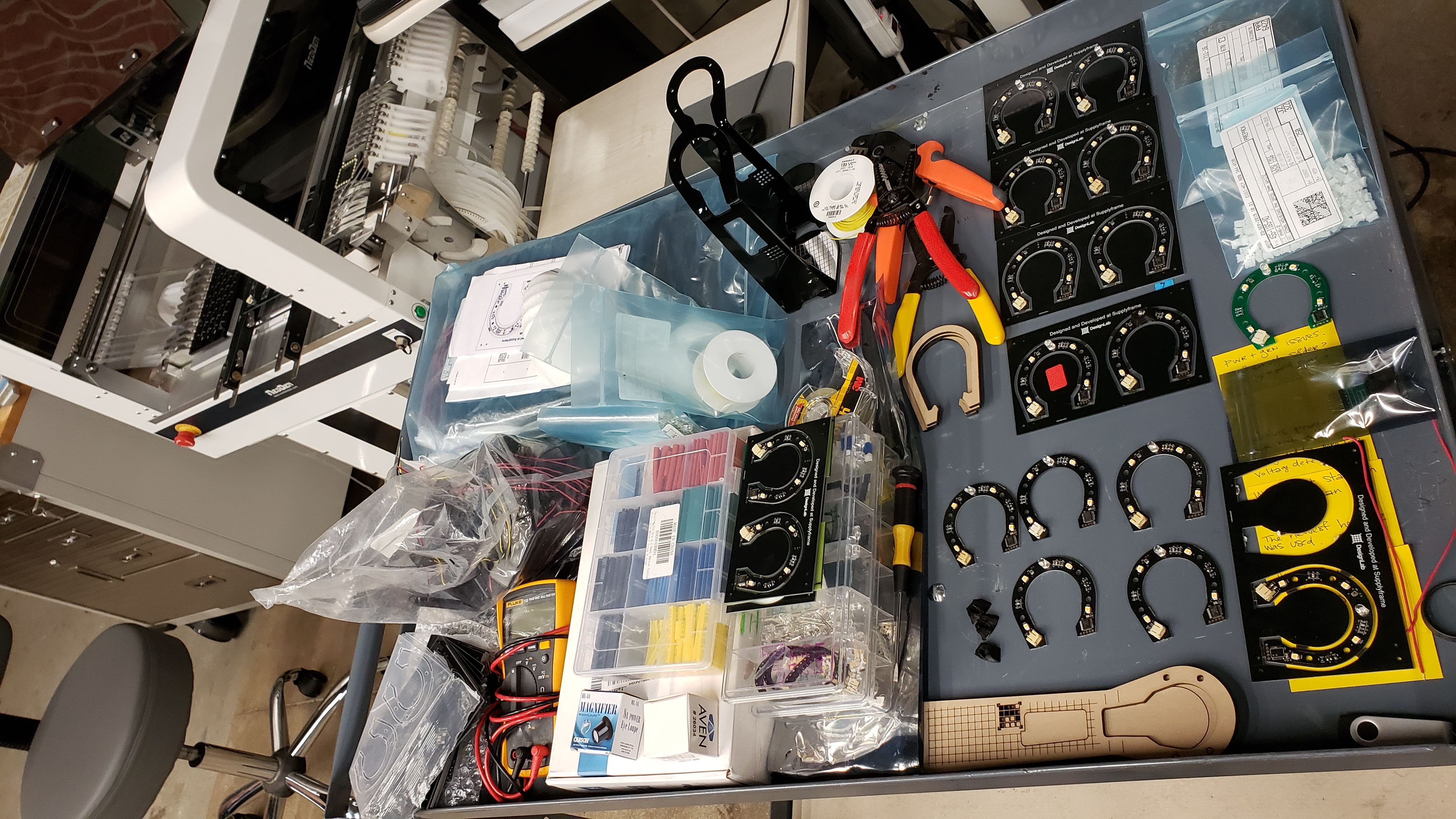

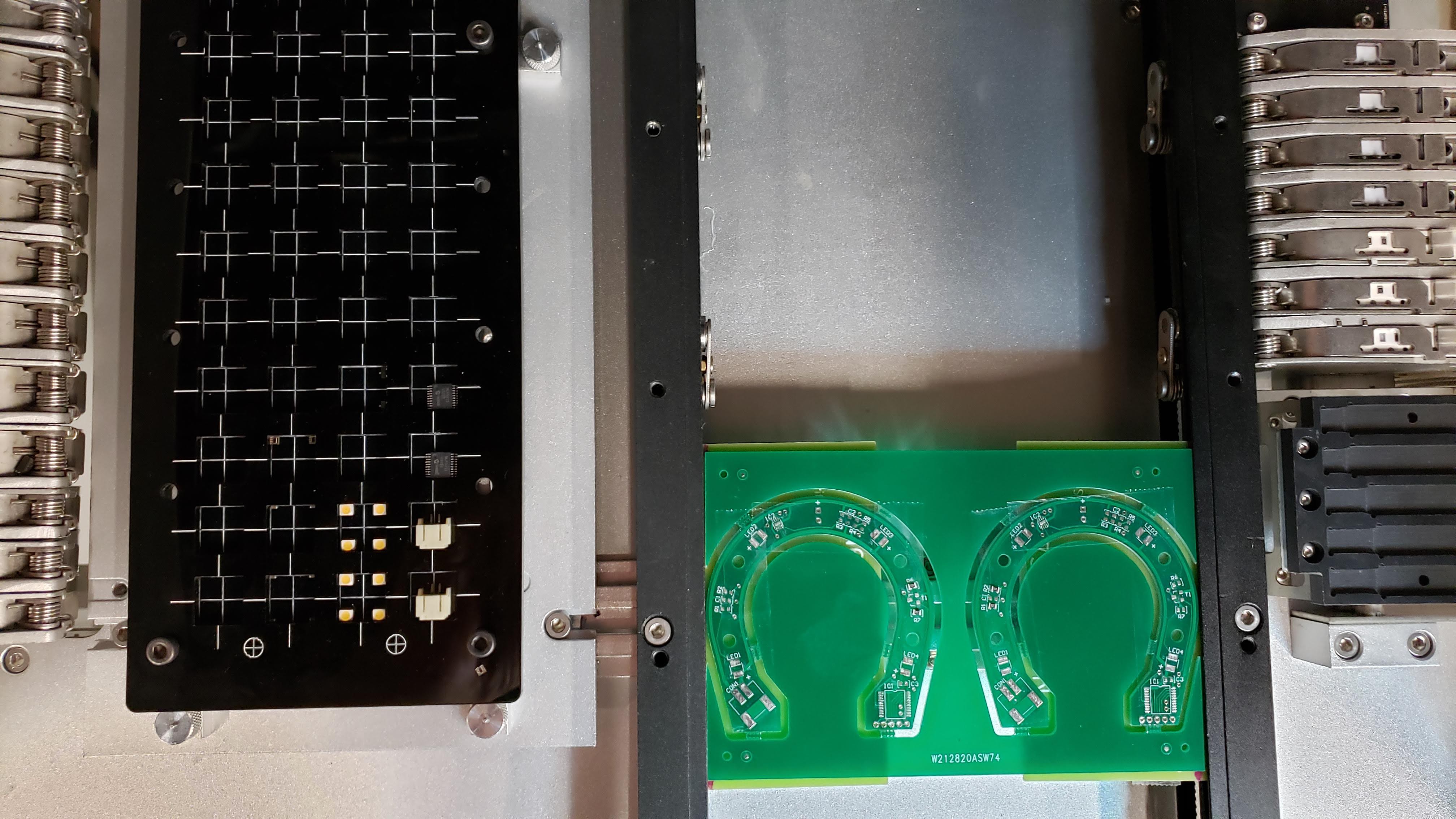

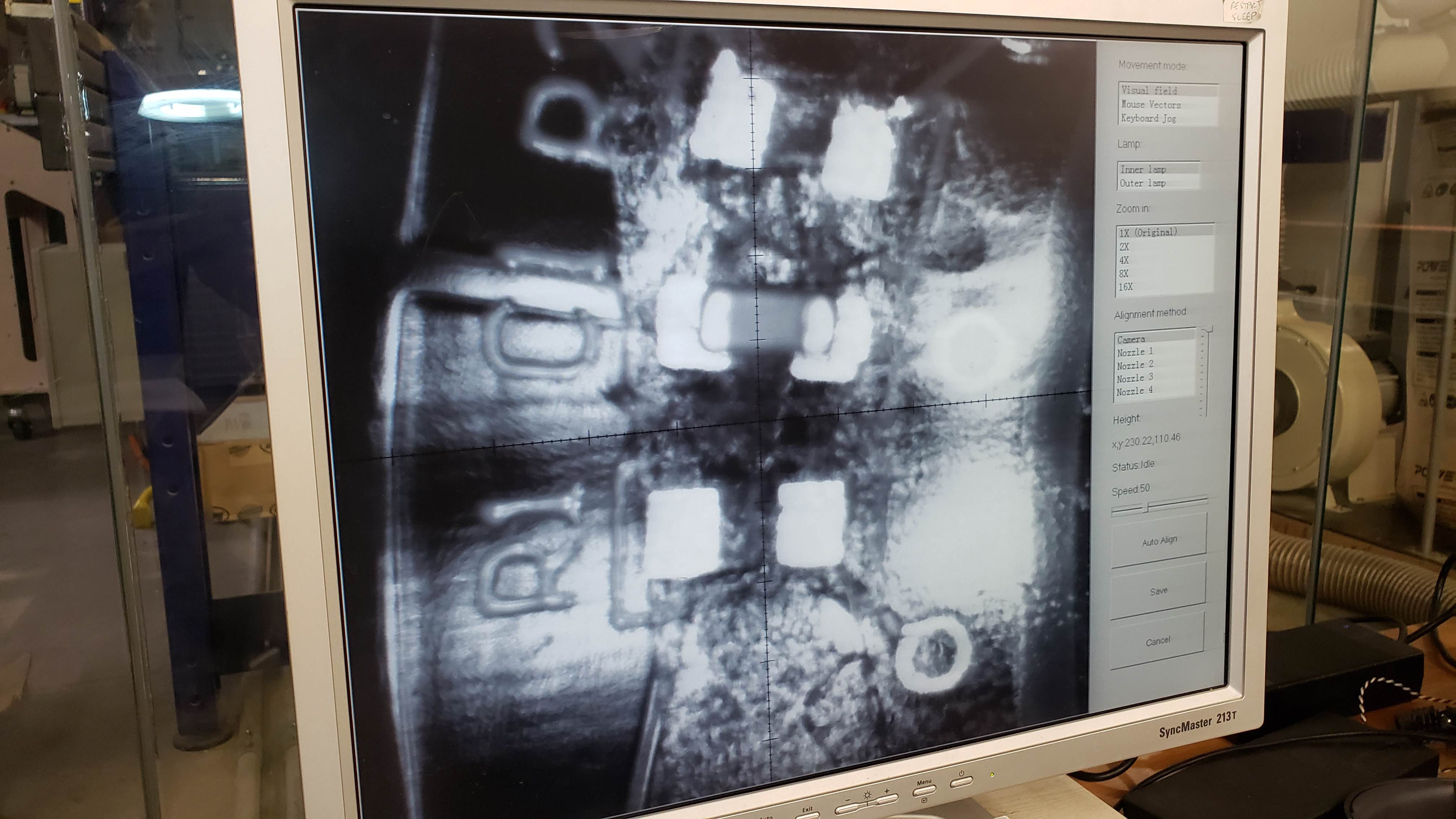

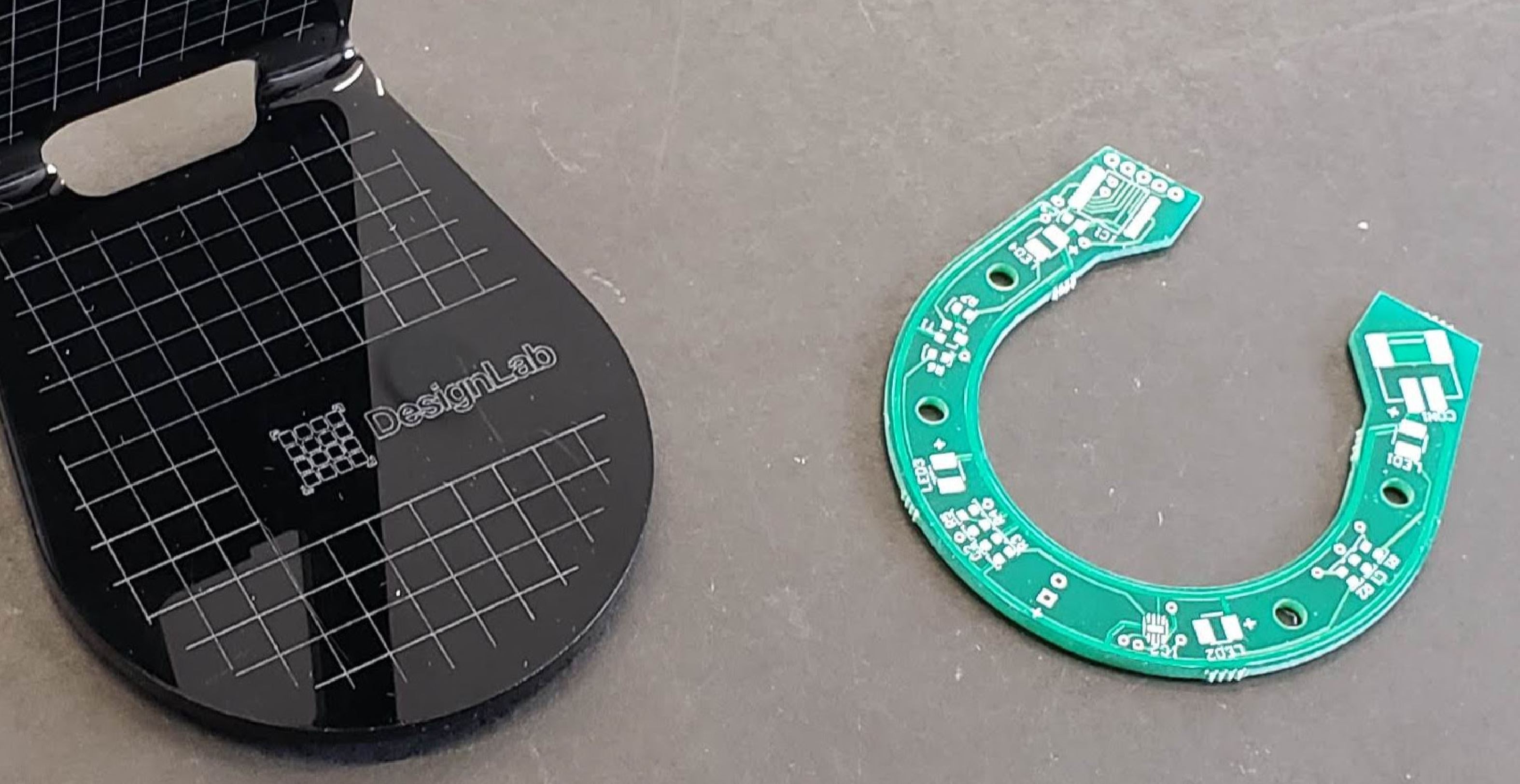

The precision on these machines is very good. The cycle to pick a component and place it on the board has quite a few steps that I am unable to describe, but Erika would in a heartbeat. Essentially, the machine takes photos of the nozzle (?), board fiducials, grabs component, goes for another selfie and then flies over to the exact location where such component should be placed.

The precision on these machines is very good. The cycle to pick a component and place it on the board has quite a few steps that I am unable to describe, but Erika would in a heartbeat. Essentially, the machine takes photos of the nozzle (?), board fiducials, grabs component, goes for another selfie and then flies over to the exact location where such component should be placed.

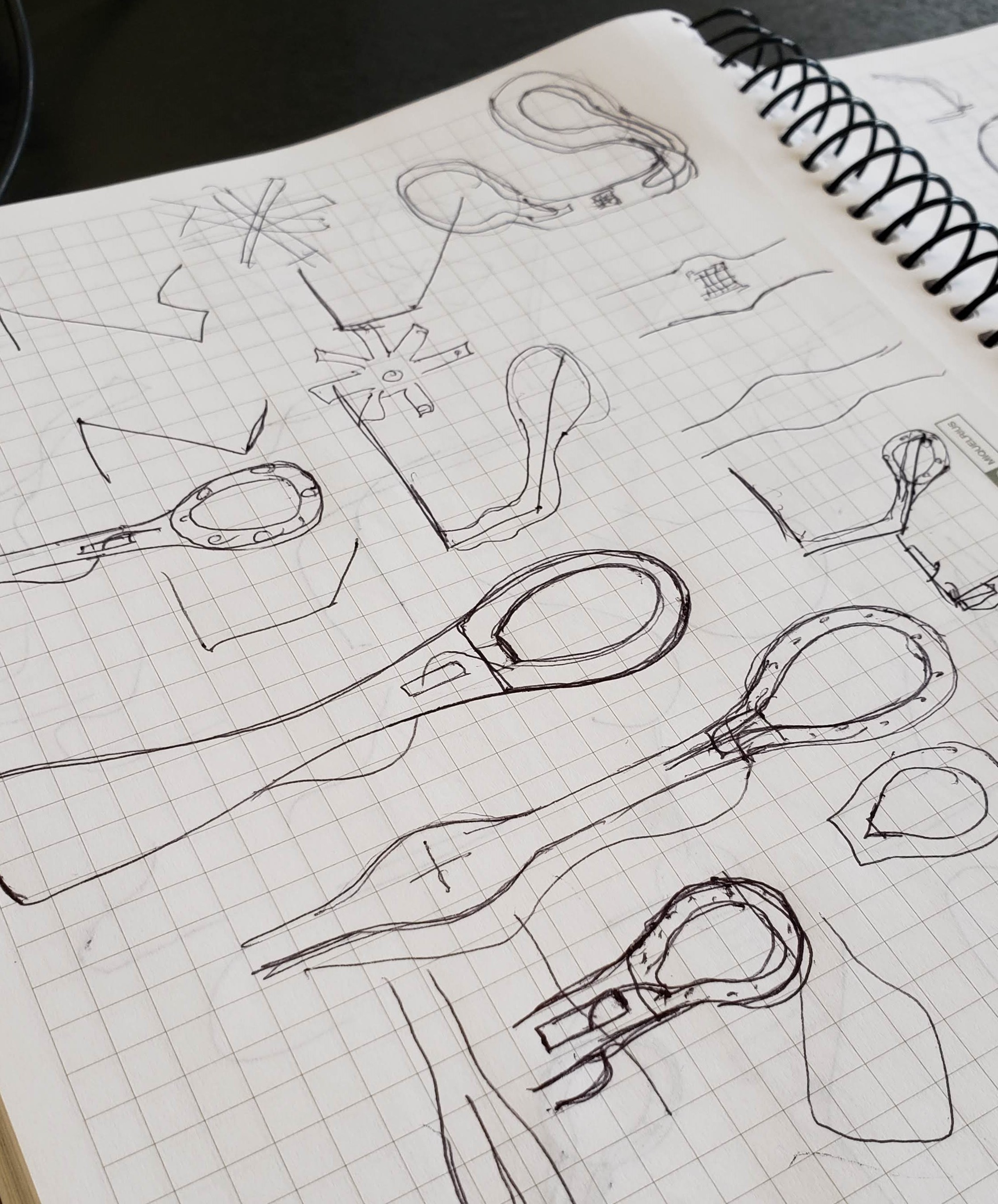

This is a very interesting part of the process because here is where electronic engineers and product designers finally butt heads.

This is a very interesting part of the process because here is where electronic engineers and product designers finally butt heads.

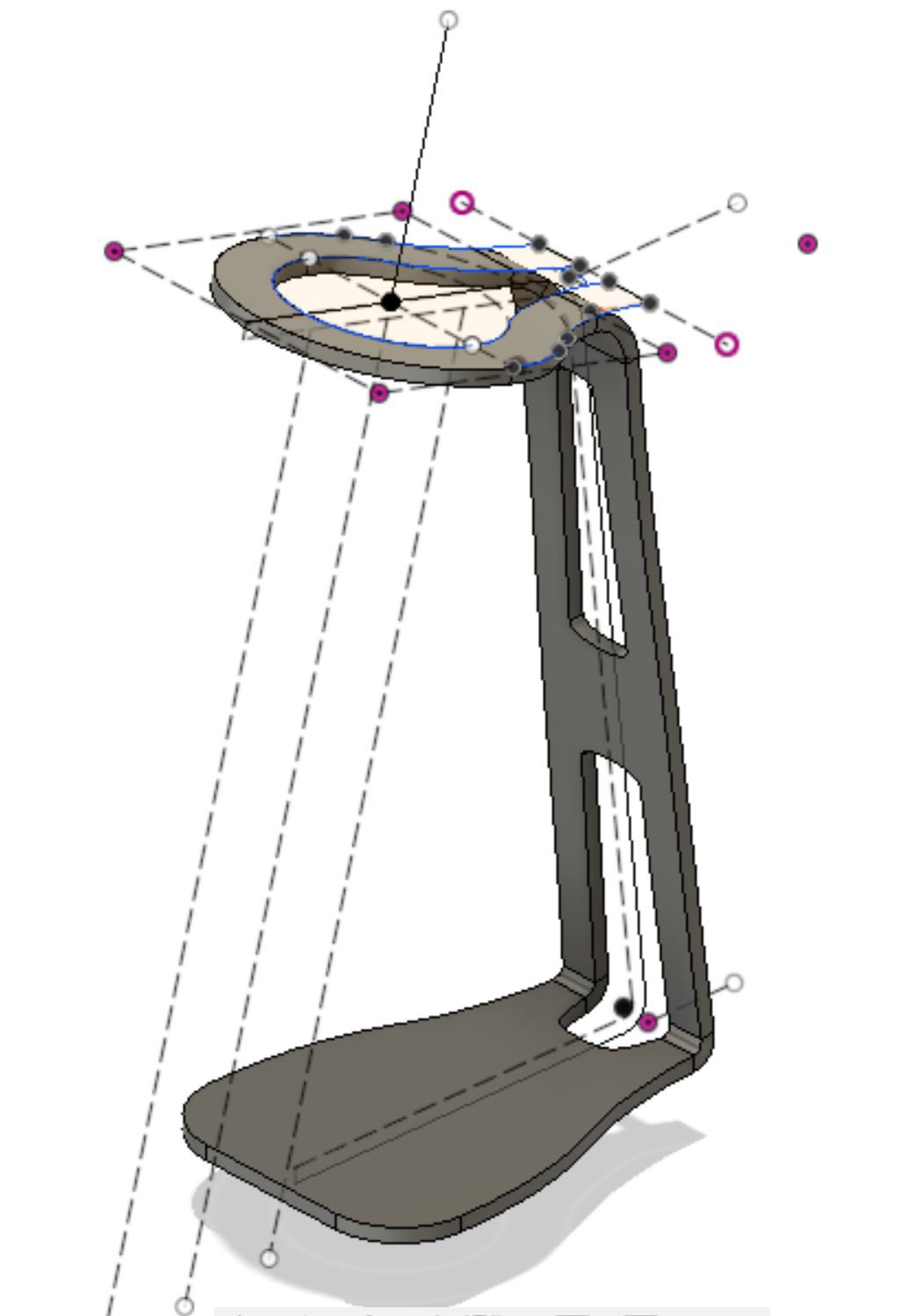

Still talking about the base, we went for a sturdier feel to it, a more geometric, kind of predictable-yet reassuring shape, and a little elevation which gives it a nice shadow and depth, plus increases stability. Batteries ended up fixed to the back.

Still talking about the base, we went for a sturdier feel to it, a more geometric, kind of predictable-yet reassuring shape, and a little elevation which gives it a nice shadow and depth, plus increases stability. Batteries ended up fixed to the back. We could say the process was started with the question: What simple, reasonably consistent and repeatable and processes is available at the Lab? Laser cutting of course. There are CNC mills and 3d printers but with laser cutting, once you have a predetermined shape, it basically becomes a "push a button" task. The next step, acrylic bending is not too complicated and I am planning to make a bending jig out of MDF soon.

We could say the process was started with the question: What simple, reasonably consistent and repeatable and processes is available at the Lab? Laser cutting of course. There are CNC mills and 3d printers but with laser cutting, once you have a predetermined shape, it basically becomes a "push a button" task. The next step, acrylic bending is not too complicated and I am planning to make a bending jig out of MDF soon.

Victor Dedios

Victor Dedios

SUF

SUF

RossGK Tangibles

RossGK Tangibles

Keenan Pinto

Keenan Pinto