Manufacturing processes were narrowed down to:

- Acrylic cutting and engraving

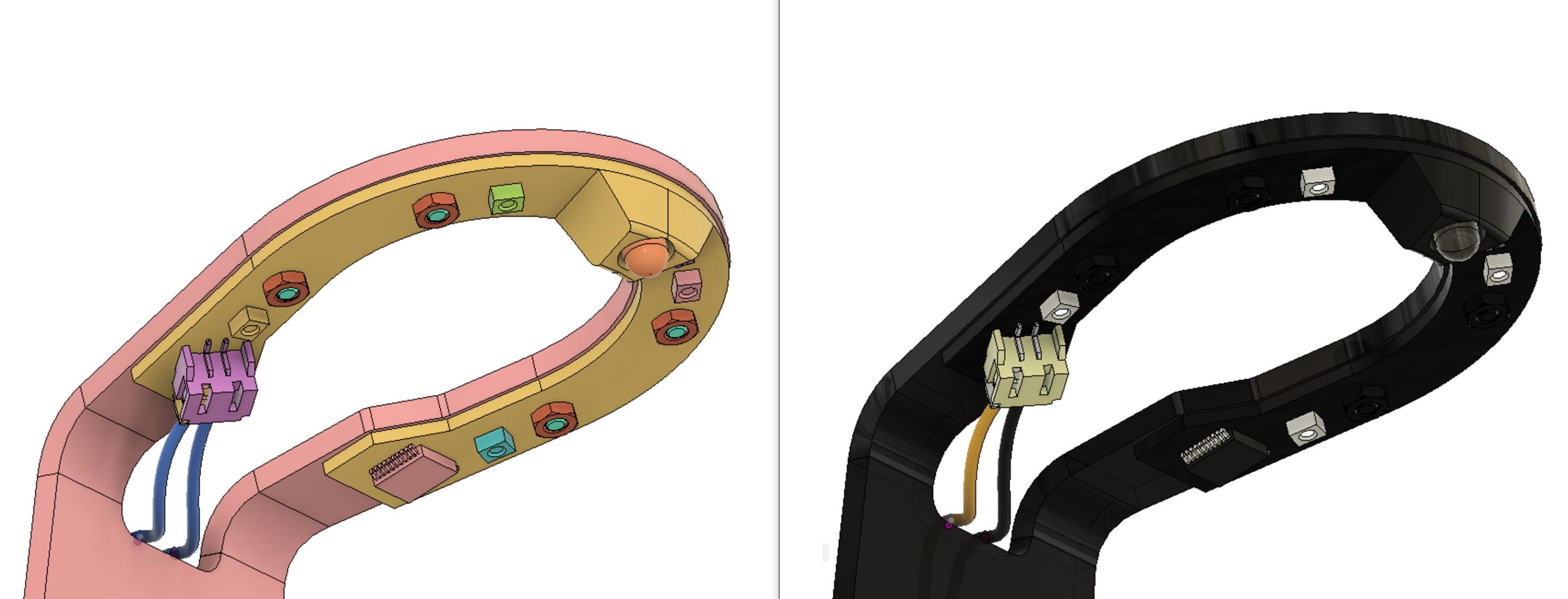

- 3D printing

- Gluing and screws fastening

The only process I did not entirely like for this project was 3D printing. Mostly because this is supposed to be part of a quick workshop and if you have done 3D printing you know how much of a mood killer it can be to wait 3 hours for a tiny-yet awkwardly oriented part on your printer. But the motion detector system needs a component that blocks the LED from the sensor up to a certain distance so with no other practical alternative, let us plan for printing in three dimensions.

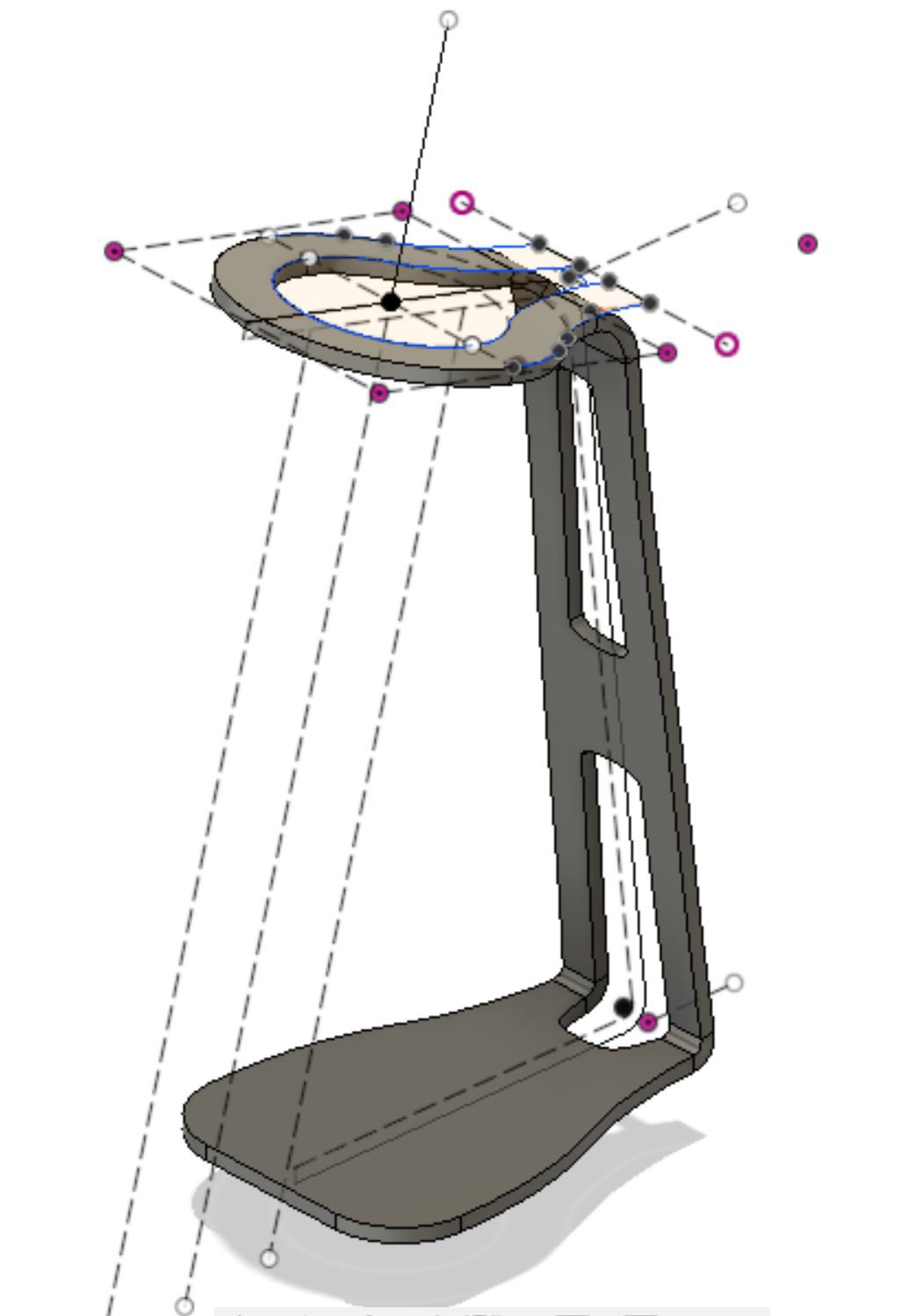

There is a rough first sketch of the lamp. The base did not look stable enough, and the shape was odd.

Giovanni

Giovanni

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.