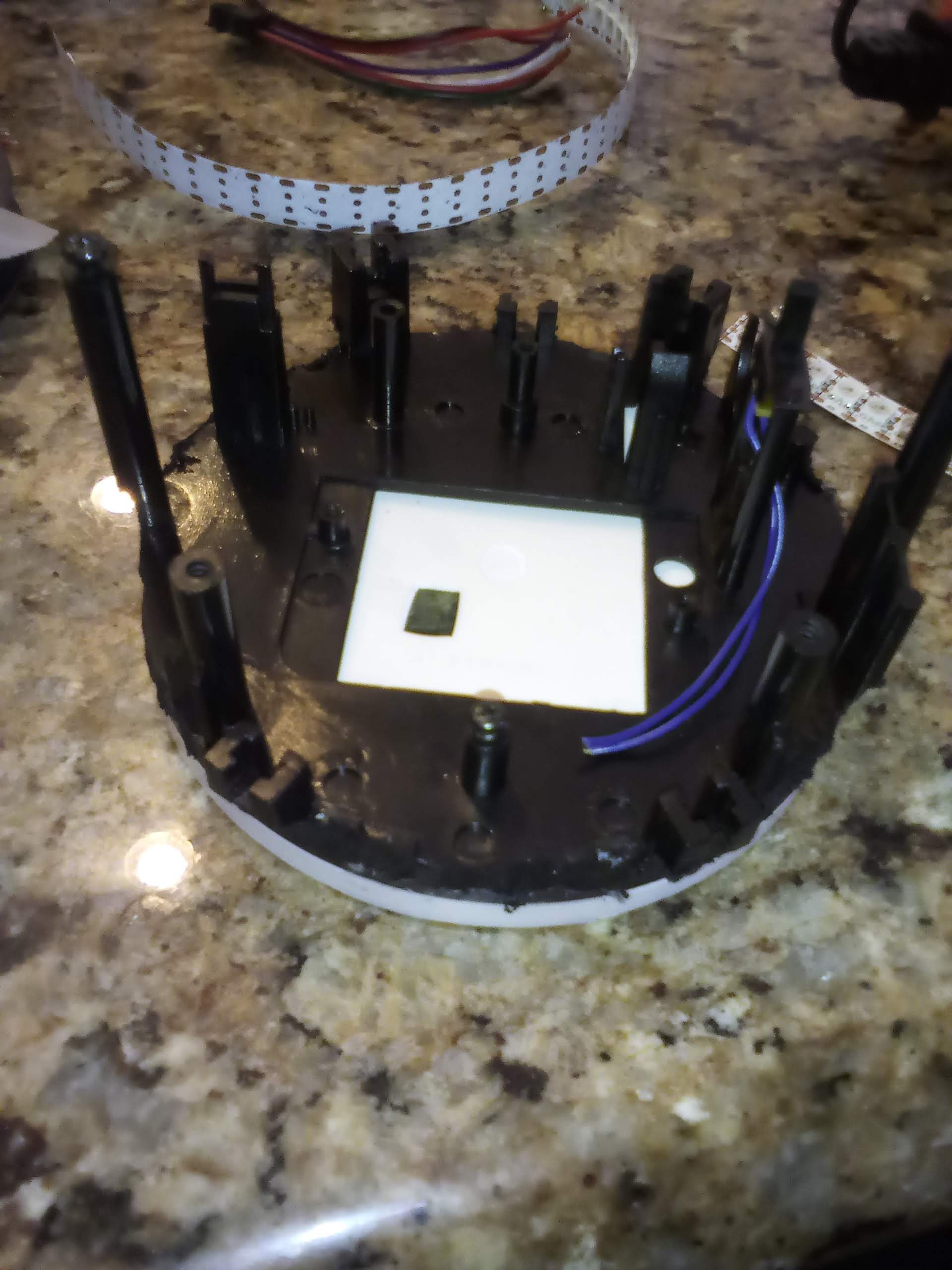

I spent a few days trying to get the original clock pieces and the new fancy LEDs to play nice together. Initially I had quite a bit of interference and I was able to take care of much of that with my friend Mr. Dremmel (note the ragged edges on the black piece of ABS):

At first glance everything looked great, as I was able to find a spot where the strip could live and I was able to reassemble the whole works. It looked something like this:

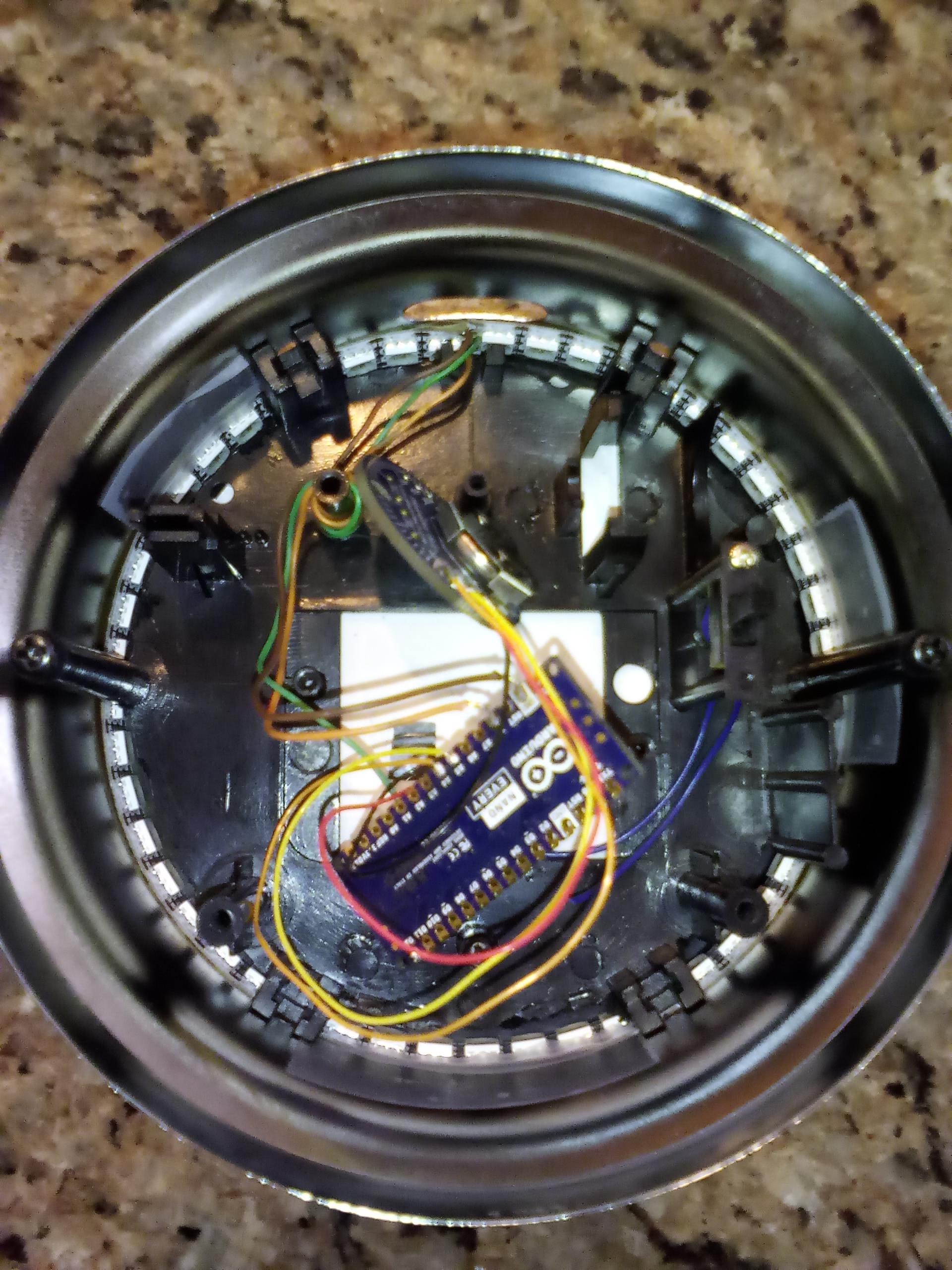

I was so excited to assemble the rest of the works (which I did) and everything "looked" great:

So I fired it all up and I saw... nothing. There is very little actual light making it to the diffuse part of the clock so I can hardly see the LED which tell the minute. Subsequently I no longer expect to be able to reuse the plastic innards which make up the mechanical section of the clock. I have zero experience with 3D CAD (beyond one class back in college) but I think it's time to make a custom part. Before I go and design something I will first reverse engineer the housing (which is a medium draw stamped sheet metal piece) and hopefully print a few test fit pieces. If I've learned anything its that I overestimated how good I would be at mechanically winging it; and under estimated how much I would need CAD for floor planning.

Andrew Cooney

Andrew Cooney

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.