I pushed up a bunch of changes to my fork of the Sawppy Repo, that, among other things, include a good number of the models I had to rework because of issues with the heat-insert holes on things like the Steering Knuckle assembly, wheel hubs, etc. being too big. This is not at all a slam on Roger or the work he's done, it's just the current reality of building things with parts made by a printer that doesn't cost as much or more than a new late-model car.

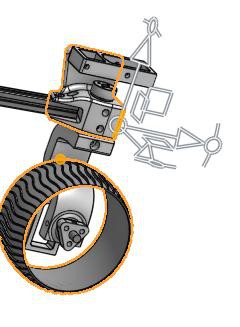

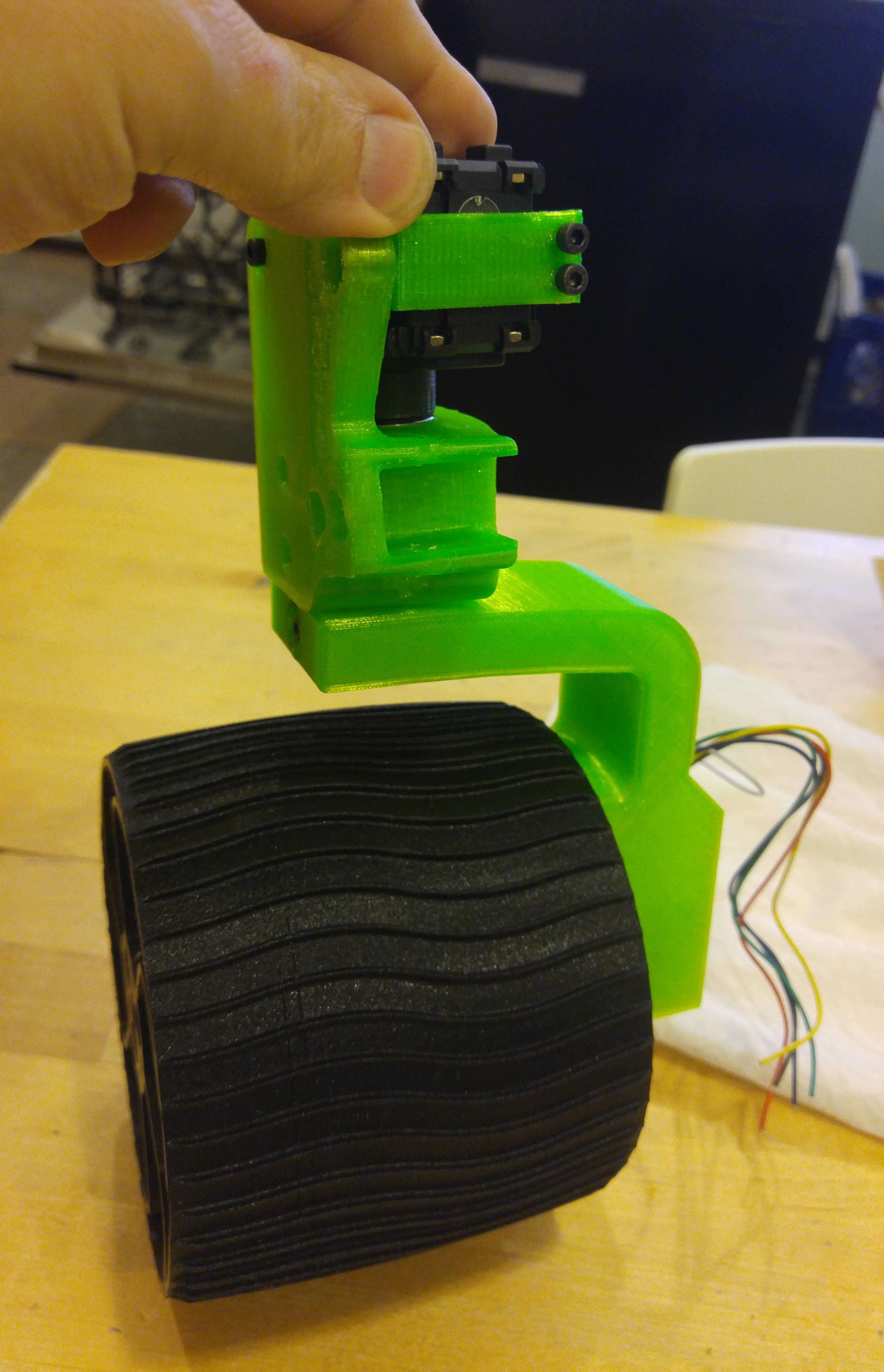

If you are going to be building something like a Sawppy be prepared to budget for failures, even if the print completes successfully. Things may just not fit right and post-processing may or may not help and you might have to resort to other methods to resolve the situation. For the Steering Knuckles that provide corner-steering for the rover, I did not re-print them but instead went with #6-32 inserts instead of the 3mm that are used elsewhere in the model. I would allot a whole extra spool for these sort of problems because printing them out at full-size in your final material is really the only way to figure it out. Resist the temptation to print out things in super-cheap PLA for fit-and-finish because it's going to flow and expand and contract differently than PETG.

Anyway, that's more of a ramble than I'd planned on about all this.

Steve

Steve

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.