Oh man, there is so much that one can forget. It's almost annoying.

Couple new rules:

- One clean cut is better than three too shallow ones

- Make ABSOLUTELY SURE that the PCB is not bent. Check this about five times before autoleveling!

Rather bend the board in the opposite direction before clamping it down as the force in Z when the milling bit tries to dig into the surface might be high enough to just push the board down and not actually cut anything useful. - Invert your X axis instead of milling in negative coordinate space when using CNC-GCode-Controller. That way you can actually do autoleveling!

- Drill LAST! If you drill on the top layer, you might poke into a hole during autoleveling on the bottom side. This is REALLY bad and happened to me more than ones. The consequence usually is that the board needs to be milled without autoleveling. That is indeed really bad

- Cut deeper that you would intuitively think. I set it up to -0.25mm and run once, even with a slightly dull v-shaped bit that I ran into the board during autoleveling a couple times

- Make your traces thicker. It's nice to see 0.25mm traces but are they needed? Likely, the answer is: no! I set everything to 0.8mm traces and have them be reliable for a very long time. Plus, it's easier to solder in case the original footprint of your part was so small that the restring after drilling is barely visible anymore

- Drill twice or three times. It's worth it to have smaller holes for wired components. I use 0.9mm for all the Arduino stuff (square pins). But for wired resistors and stuff, it's good to make the extra effort to drill a smaller hole like 0.4mm to 0.5mm

- Drill deeper than you would intuitively think! Nothing is worst than realizing that one has to manually redrill the 150 holes because the drill bit just poked about 90% of the way through! The board is 1.6mm thick and the copper is flexible. If you don't have the sharpest bits on the planet, it's worth just drilling 2mm and be done with it.

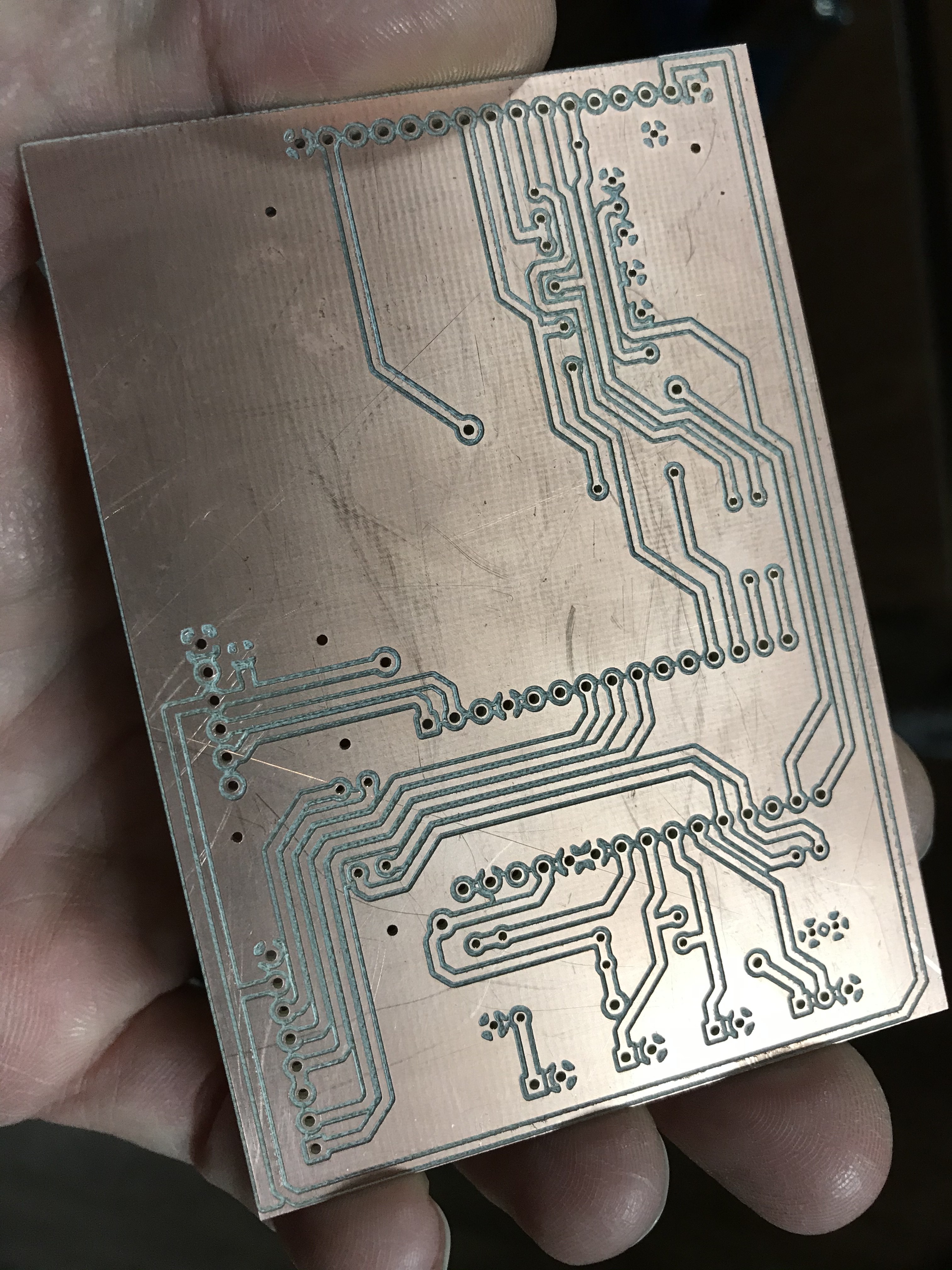

This came out nearly perfect! And I haven’t even cleaned it up, yet!

Very pleased! :)

Timo Birnschein

Timo Birnschein

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.