Finally tested a lot of ideas & new method of MCH mounting:

- Pre-assembled aluminium heater cartridge (not MCH).

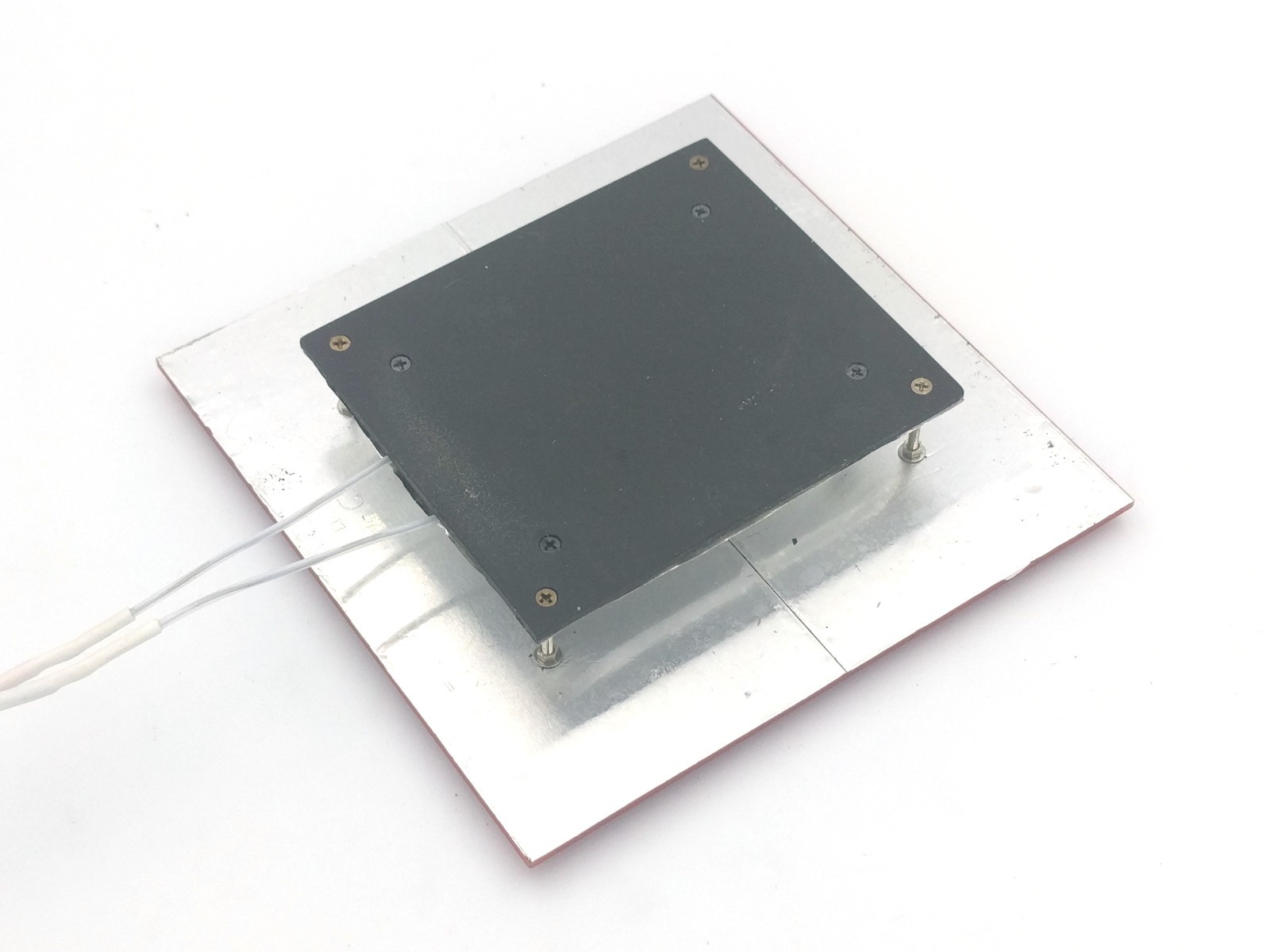

- MCH mounted on copper plate (70*60*2mm).

- MCH mounted on aluminium plate (70*60*2mm).

Here is "almost final" candidate:

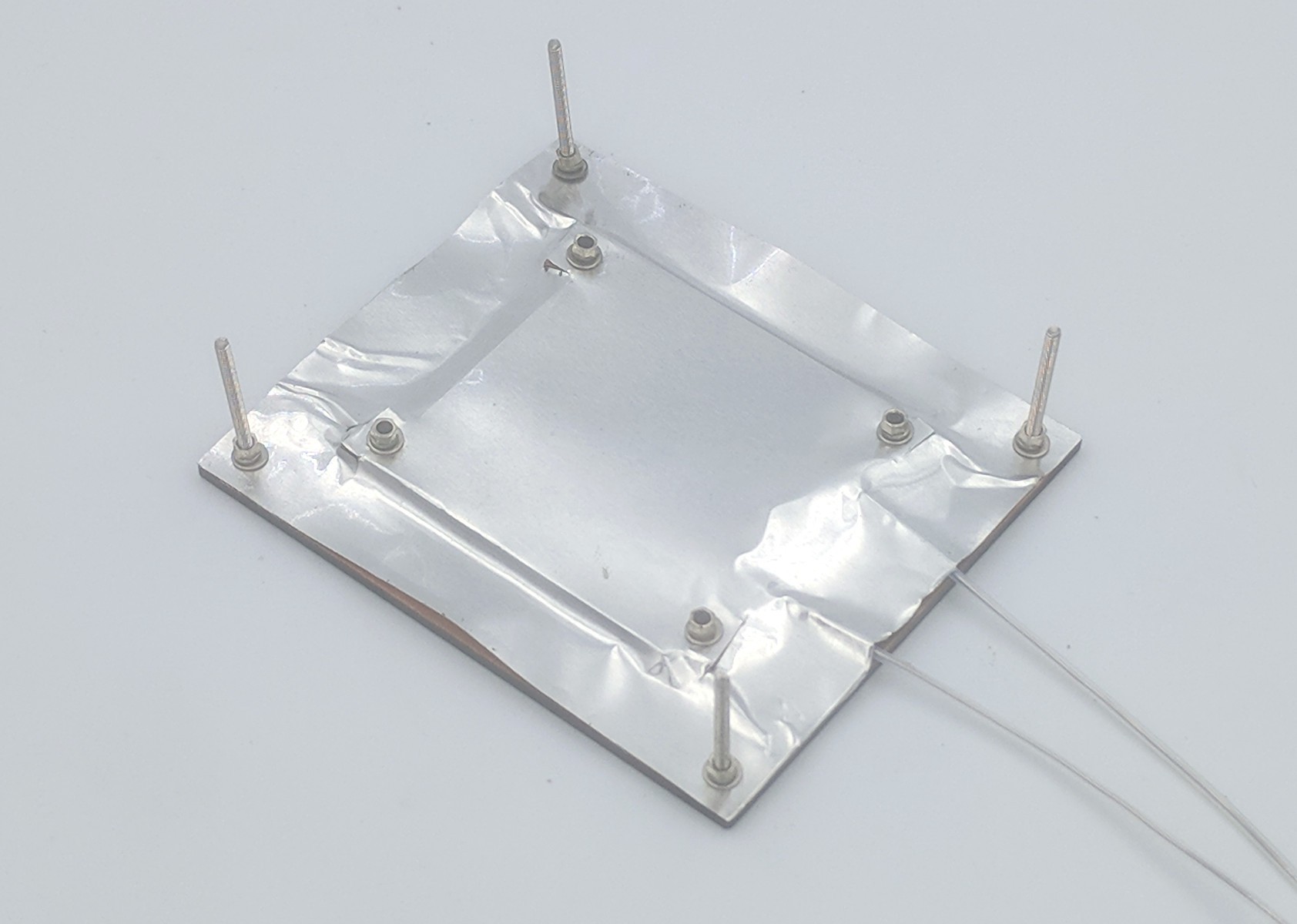

Bottom:

All assembly details and more photos are published on gihtub (will be updated soon): https://github.com/puzrin/reflow_micro/blob/master/doc/heater_assembly.md

Key points

- M1.6 stainless steel screws are enough for good thermal insulation. PCB stays cold.

- New plate has 60*50...70*60 mm of working area with acceptable temperature difference. That's ok for 99.9% of hobby projects.

- ~40-50W needed to heat plate of this size to 270C.

- Sizes & technology confirmed, can start PCB trace.

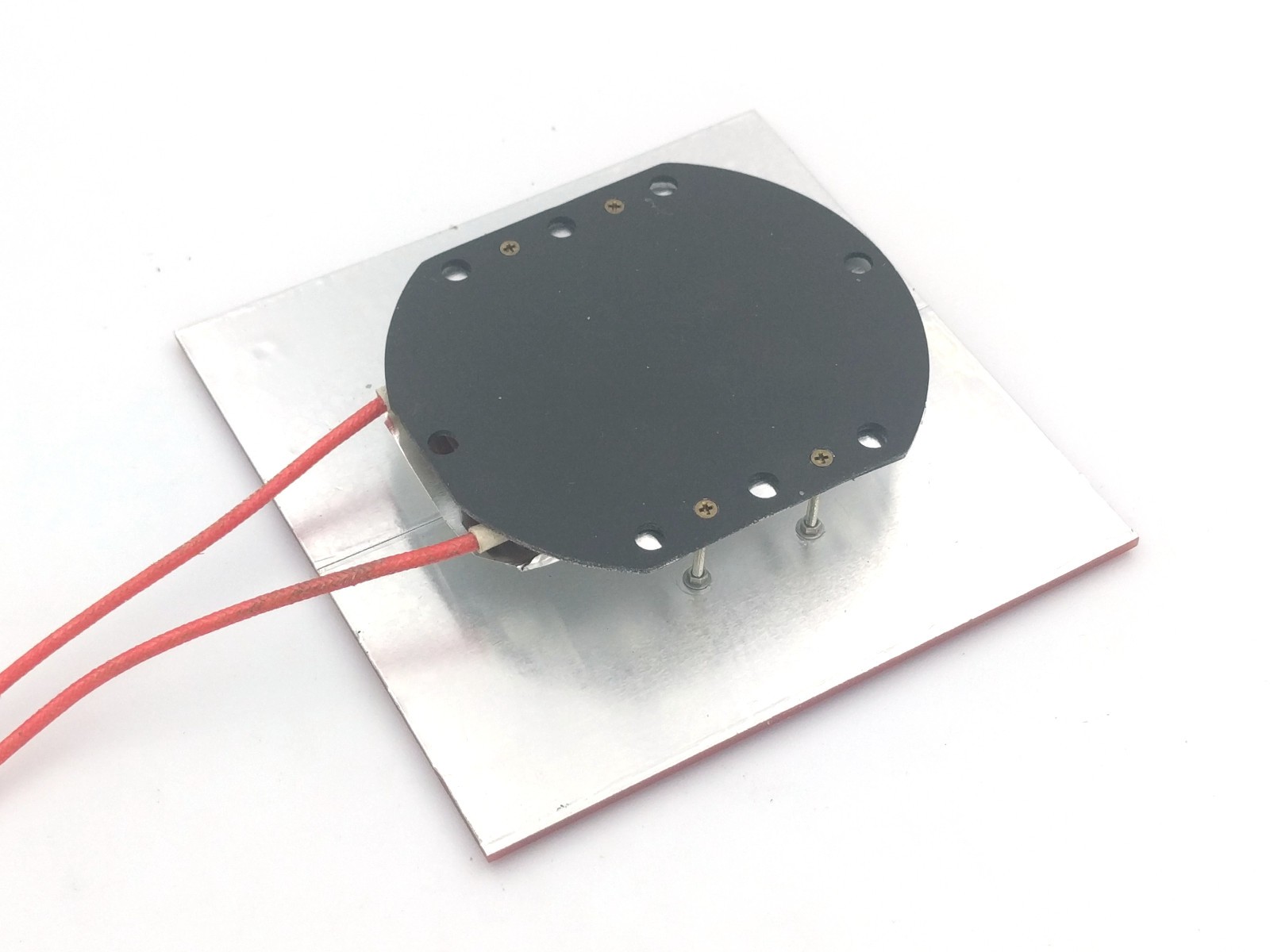

Rejected attempts

Not everything was fine. Unfortunately, rejected aluminium heater cartridges:

- They have not enough power to reach desired temperature (announced 300W are for cold state, at 220-230C power drop to 30W).

- Power wire are fat and become too hot - difficult to place in compact device.

- No 110v versions (for USA)

Also, i had to reject copper plates in favour of aluminium. Copper is oxidised too fast on high temp. I hoped oxidised film to stop process, but it crumbles after big temperature change. Probably, this can be fixed by protecting plates with paint from all sides, but that's not convenient.

40*40*1.7mm MCH heaters were tested, but found 50*50*2mm more comfortable. Price difference is very small.

What's next

As been said, new approach looks good at first glance, and now it's safe to route PCB and design 3d-printed case. All next experiments can be done in parallel.

It still worth to clarify plate thickness. 2mm aluminium plate gives ~ 15C difference in working area (5mm margin from borders). That's enough, with big reserve, for leaded paste (i doubt anyone use lead-less paste for hobby projects). But it would be nice to improve if possible.

I'm waiting 3mm and 4mm alu sheets for new plates and hope to publish final decision & measurements next week.

Vitaly

Vitaly

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.