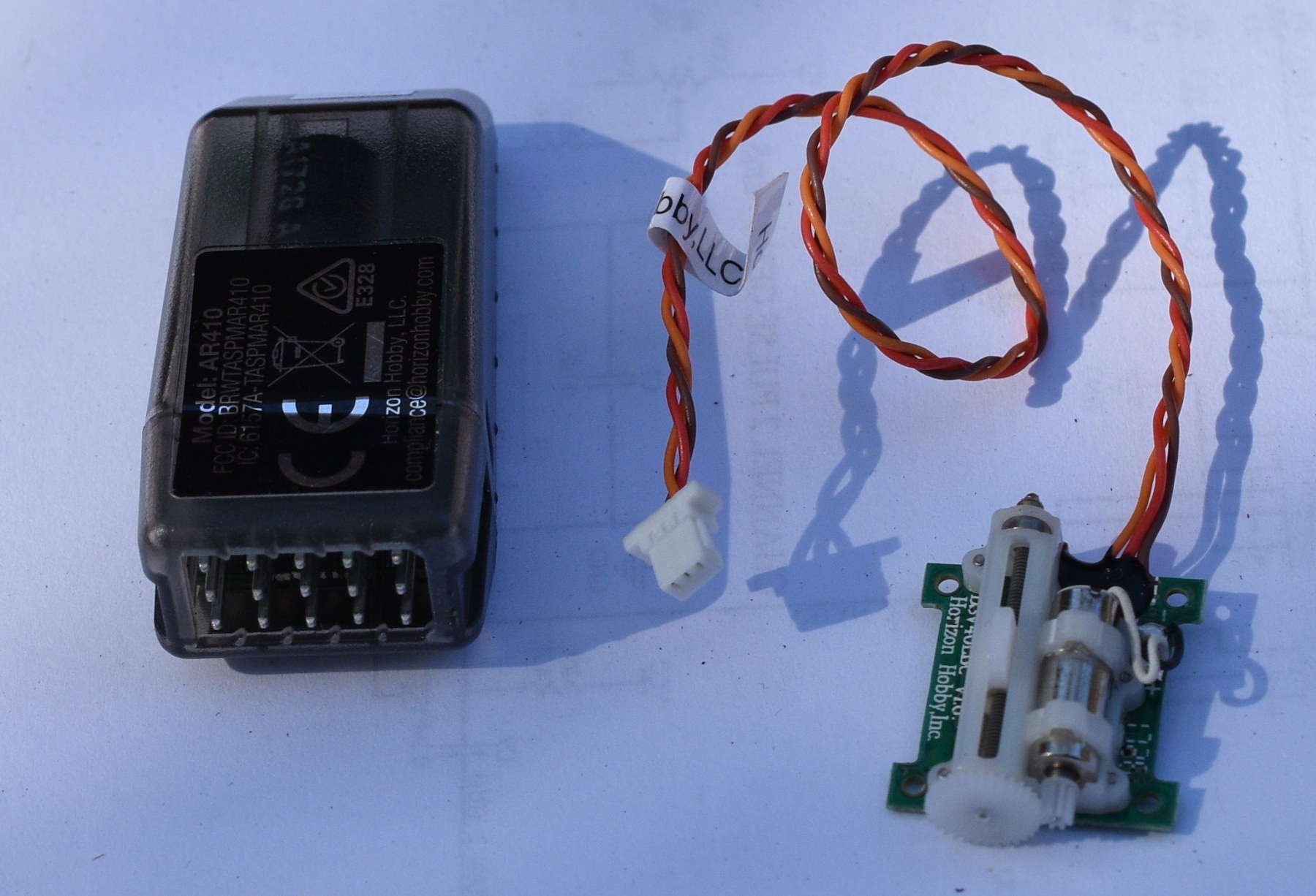

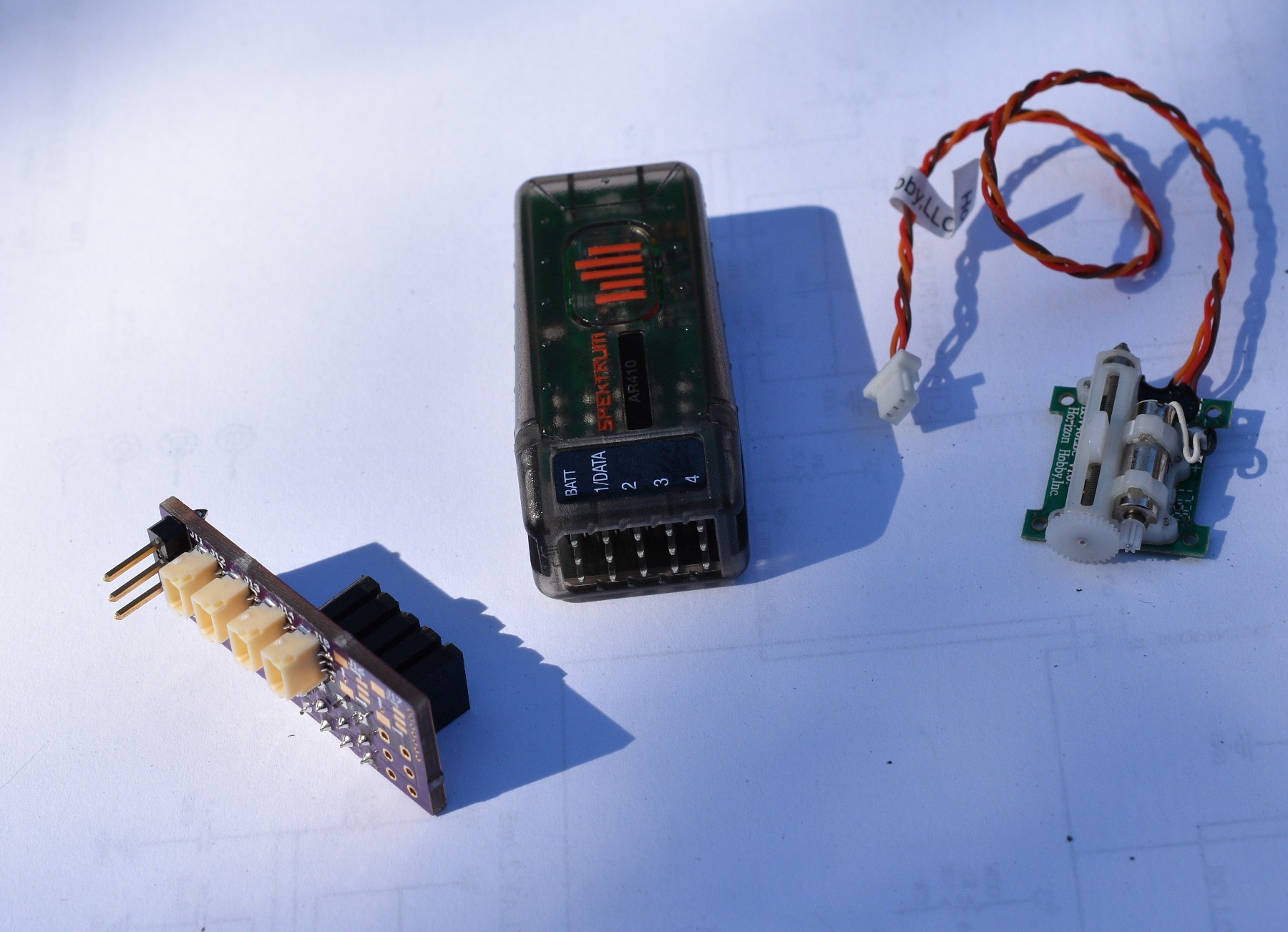

Micro servos are equipped with a connector that is not compatable with the standard 0.100" pin connectors on full sized RC equipment. There are some voltage issues involved as well, as the micro servos are designed to run from a single cell LiPo (3.2V-4.2V) battery instead of the 4 NiMH batteries (4.8V-5.2V) on older systems. The Spectrum AR410 and AR620 receivers that I have will operate down as low as 3.5V, so there is enough overlap for this to work without problems.

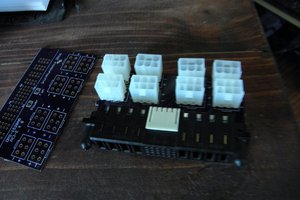

The receivers that I have all have keys molded into the cases to ensure correct connector insertion for the battery and servo connectors. The proper connector shells have bevels on the corners on one face of the connector. Standard Molex and readily available solder tail versions of this connector don't have the bevels. After searching unsuccessfully for a solder tail connector with the bevelled corners, I took a file to the Molex connectors that I had and was able to put enough of a bevel in the corners without cutting through the shell completely.

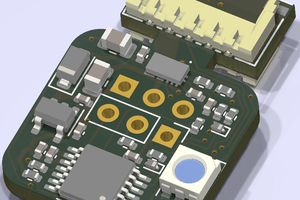

Servo connectors are JST type SH connectors 1mm pitch that are readily available in surface mount or through hole. I chose surface mount to minimize protrusions on the side of the board facing the receiver.

The Schematic, Bill of Materials and Gerber files are in the files section. Mouser is my preferred supplier, but their selection of JST parts did not include the type SH connectors, so they came from Digikey.

Bharbour

Bharbour

Josh Blevins

Josh Blevins

lion mclionhead

lion mclionhead

Charles Lakins

Charles Lakins

Wissam Tedros

Wissam Tedros