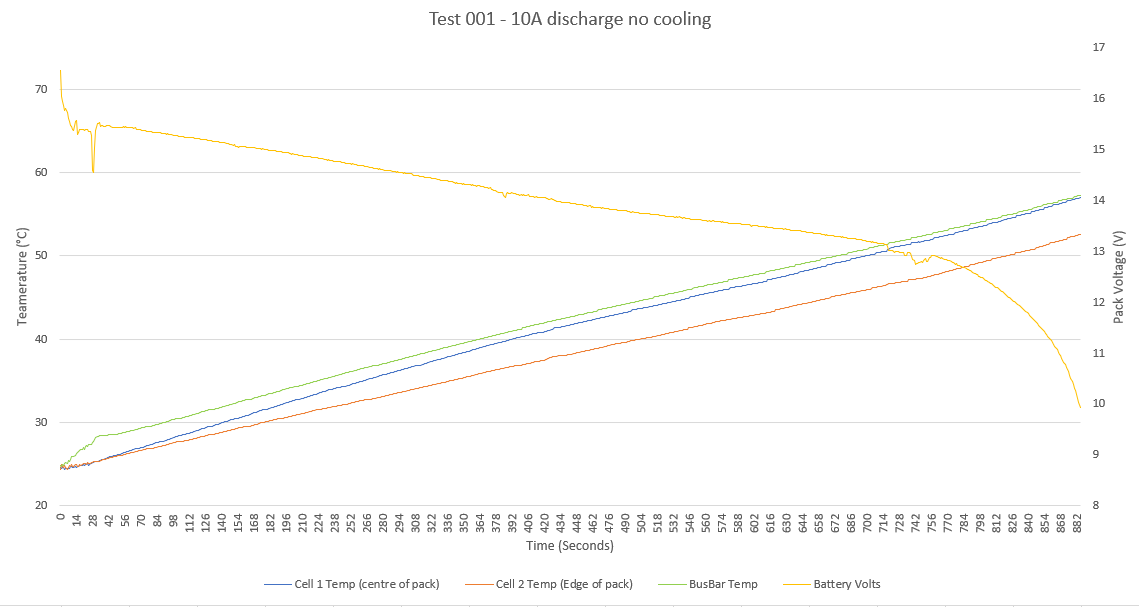

Test 001 - 10A No Water Cooling

- Had to set current pot at start so first few seconds values are unreliable

- load set to 10A

- No water cooling

- Cells insulated with tea towel to simulate being in centre of pack

- Glue on tape securing cell temp sensors softened towards the end. Sensors could move away from cells. This may have been giving unreliable readings

- Cut off at 2.5V per cell, 80°C on busbar and cells

- Test ended due to low voltage

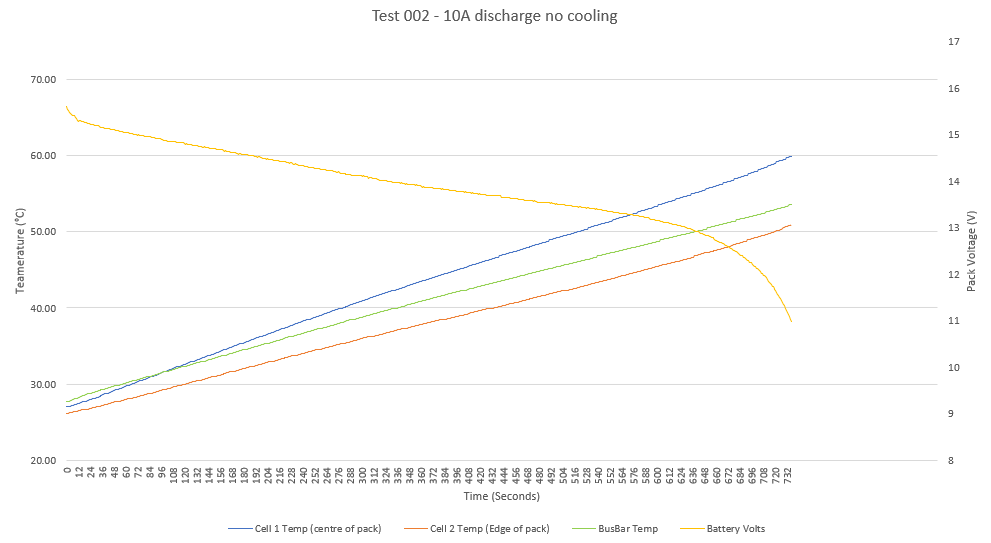

Test 002 - 10A No Water Cooling

- load set to 10A

- no water cooling

- cells insulated with tea towel to simulate being in centre of pack. Wrapped more tightly since test 001

- sensors now firmly fixed to cells

- cut off at 2.75V per cell, 80°C on busbar and cells

- Test ended due to low voltage

![]()

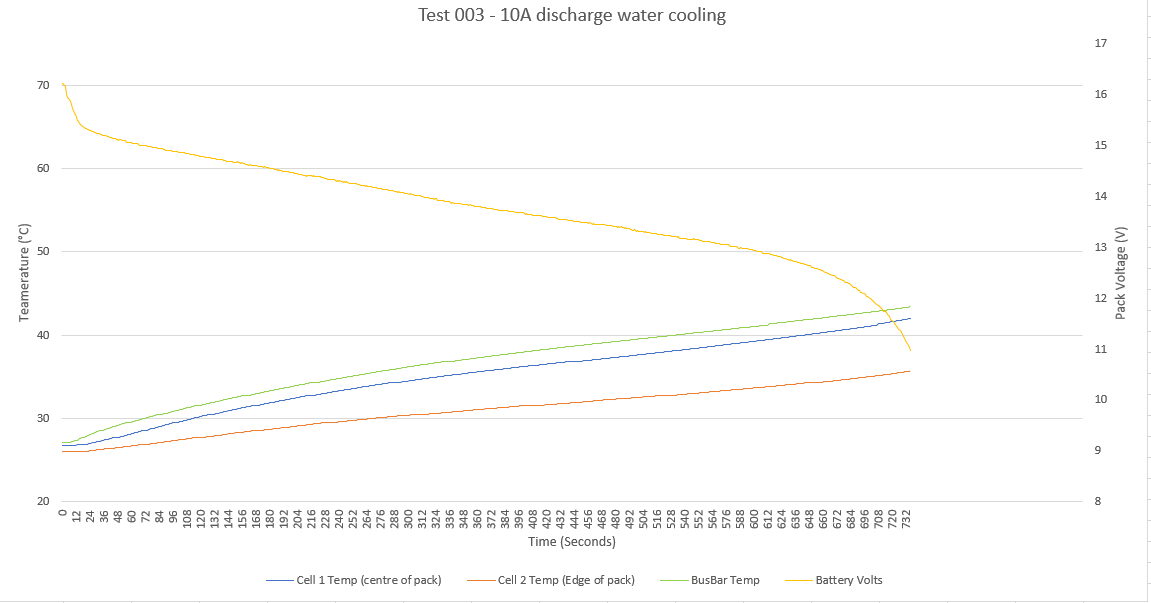

Test 003 - 10A With Water Cooling

- load set to 10A

- water cooling on, 0.5l water start temp 26°C finish 28°C.

- cells insulated with tea towel to simulate being in centre of pack.

- sensors now firmly fixed to cells

- cut off at 2.75V per cell, 80°C on busbar and cells

- ended due to low voltage

- Cell temperature significantly reduced from earlier tests with no cooling.

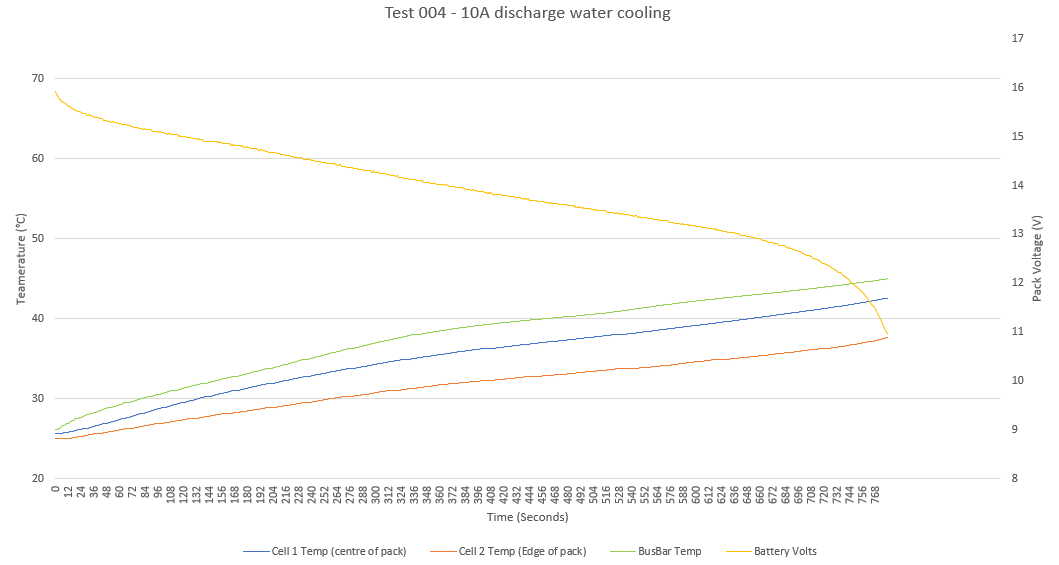

Test 004 - 10A With Water Cooling

- load set to 10A

- water cooling on, 0.5l water start temp 26°C finish 29°C.

- cells insulated with tea towel to simulate being in centre of pack.

- sensors now firmly fixed to cells

- cut off at 2.75V per cell, 80°C on busbar and cells

- ended due to low voltage

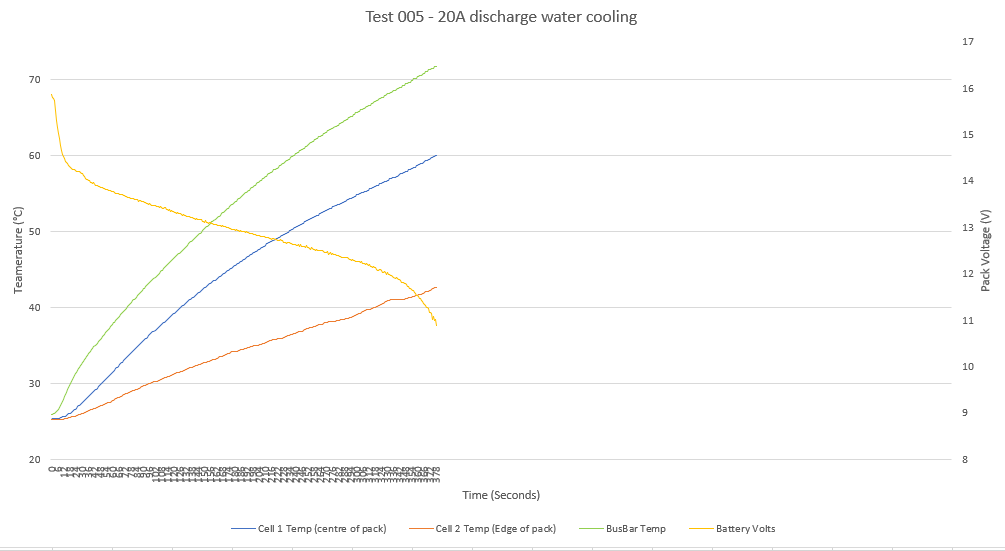

Test 005 - 20A With Water Cooling

- load set to 20A. (was set to 10 at start of test, had to set pot, hence gradual fall in voltage at start of test)

- water cooling on, 0.5l water start temp 25.5°C finish 28.2°C.

- cells insulated with tea towel to simulate being in centre of pack.

- sensors now firmly fixed to cells

- cut off at 2.75V per cell, 80°C on busbar and cells

- ended due to low voltage

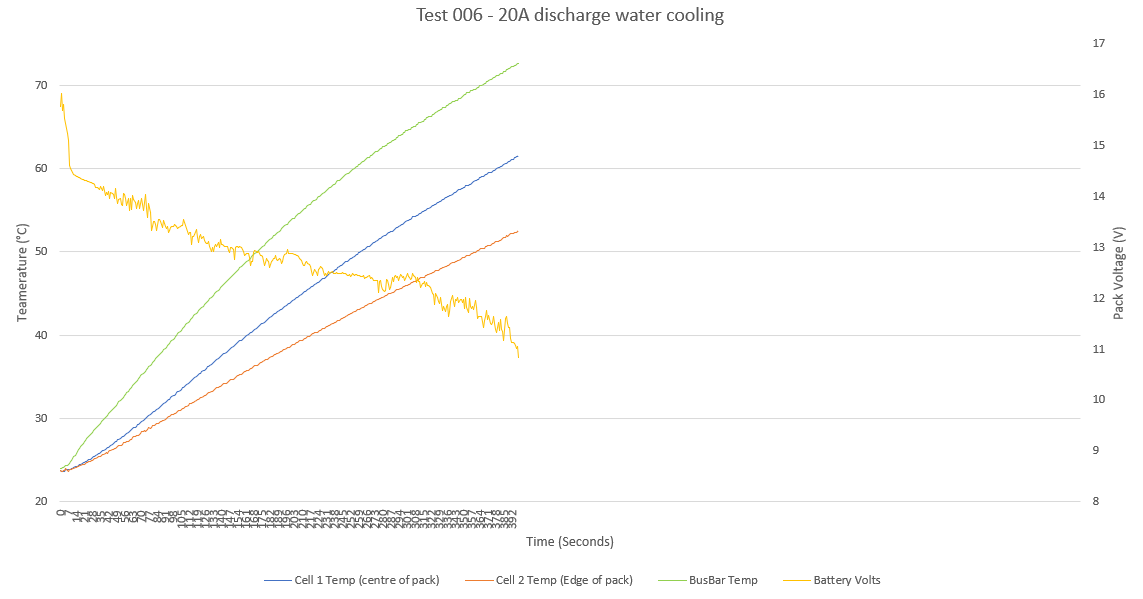

Test 006 - 20A With Water Cooling

- load set to 20A

- water cooling on, 0.5l water start temp 25.5°C finish 28.2°C.

- cells insulated with tea towel to simulate being in centre of pack.

- sensors now re positioned into wooden frame and replaced with bead sensors (smt thermistors easily damaged)

- cut off at 2.75V per cell, 80°C on busbar and cells

- ended due to low voltage

- Something has happened to dummy load or data logger. Spurious voltage reading.

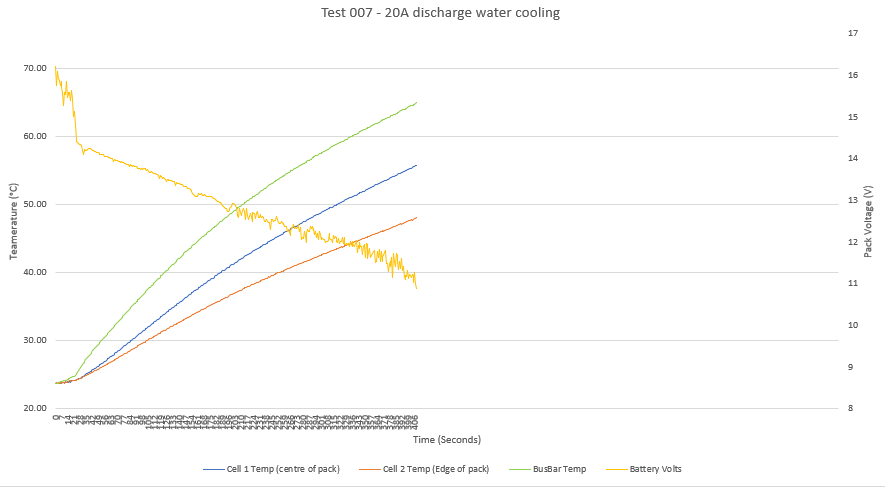

Test 007 - 20A With Water Cooling

- load set to 20A

- water cooling on, 0.5l water start temp 25.0°C finish 29.0°C.

- cells insulated with tea towel to simulate being in centre of pack.

- sensors now repositioned into wooden frame and replaced with bead sensors to allow space for more cooling tube coils 12 rows of cooling coils (previously 7)

- cut off at 2.75V per cell, 80°C on busbar and cells

- ended due to low voltage

- checked connections from previous test but voltage reading still suspect.

Results

The method of cell cooling using wraps of pneumatic hose clearly has some useful effect. During 10A testing the peak temperature was 60°C without cooling, 42°C with cooling.

During the 20A testing the temperature peaked at 62°C with cooling and 7 180° wraps per cell. Increasing wraps to 12 reduced temperatures to 56°C.

I have yet to test a 20A discharge with water cooling disabled. May have to keep a fire extinguisher handy. Will update soon.

Other thermal coupling methods are to be tried also

Rory

Rory

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.