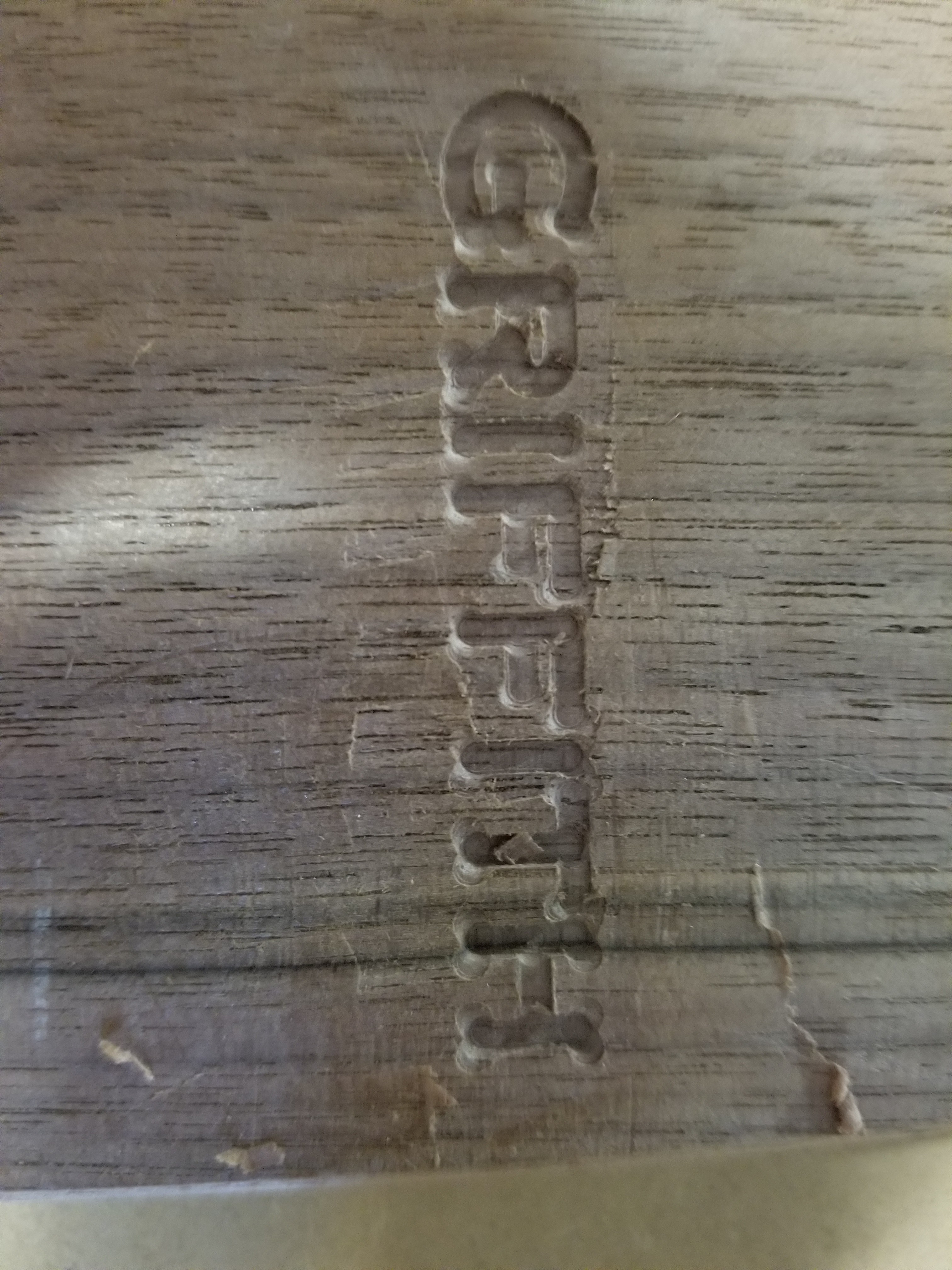

During milling process

After milling, went over it with a hand plane

Couple of observations right off the bat. The "clamps" that came with the machine are both worthless and frustrating. On the todo list for later is to get some superglue and painters tape and try this technique https://www.nyccnc.com/super-glue-fixturing/

For now, I'm using a 1.5mm burr bit that came with the machine.

Griffith Test 1:

Stepover 1.429

Depth per pass 0.179

Feedrate 787.4

Plungerate 196.850

RPM 10000

All movements are working properly meaning x y and z all travel in the correct directions. The quality looks more like the bit is tearing the wood rather than carving it. There are "fuzzy" pieces of wood still attached to the workpiece all around the carved portions.

Since this is just a starting point, I have absolutely no idea which way to go from here. Am I using the wrong type bit? Too fast, too slow, too much depth at one time? Maybe this is just the best it gets. Who knows? At this point I am planning on letting the job finish, snap some pictures to add here, and asking for guidance from the facebook group.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.