It's said that a picture is worth a thousands words, but I am sure my sketches' worth are more like five to six (in an optimistic measure).

Anyway, I have been having difficulties thinking about the bottom surface of LCLC.

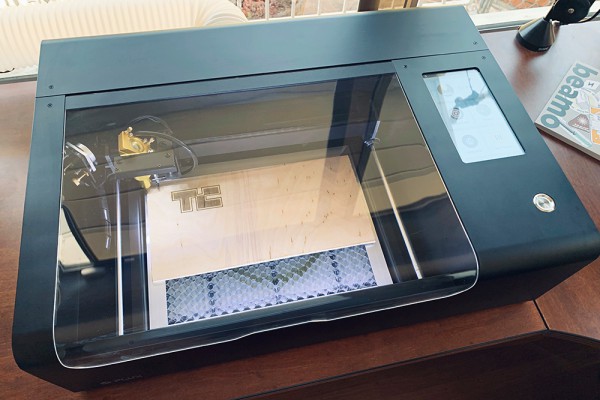

See those diamond-shaped grill/web on the bottom? That is the protective piece (I could not find what that is called!), securely holding the workpiece while minimizing any damage from the laser, usually by having a low normal-surface area and offsetting the workpiece from the laser cutter.

Many printers make use of that metal web design, although the (glass) fiber lasers I have seen had triangular spikes holding the piece.

Because the core concept of LCLC is minimizing the scale of the design by having all the parts pinned down on a (wooden) frame, like how Sienci Labs' LongMill) a big conflict was kind of inevitable, especially because I couldn't find the things being sold online.

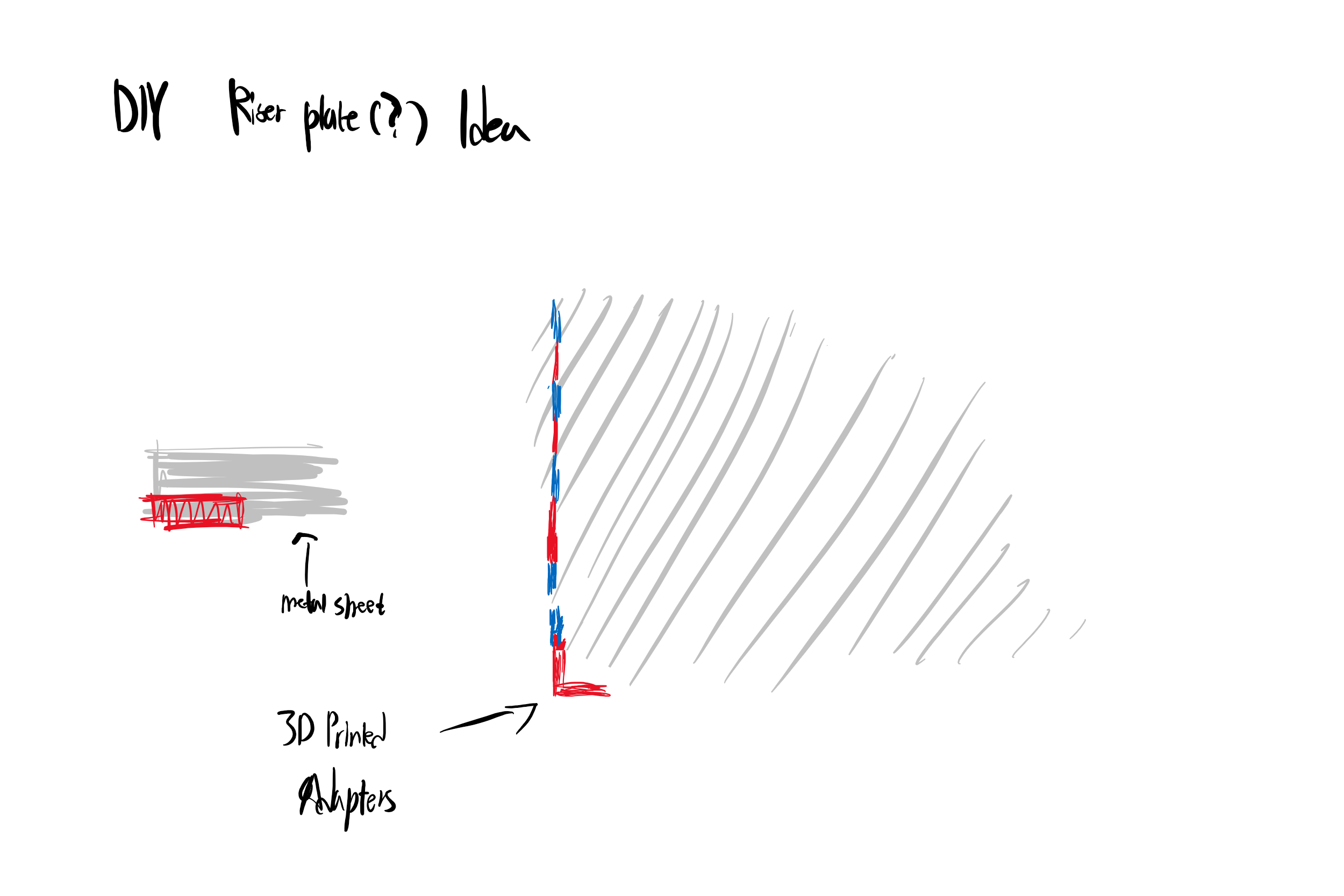

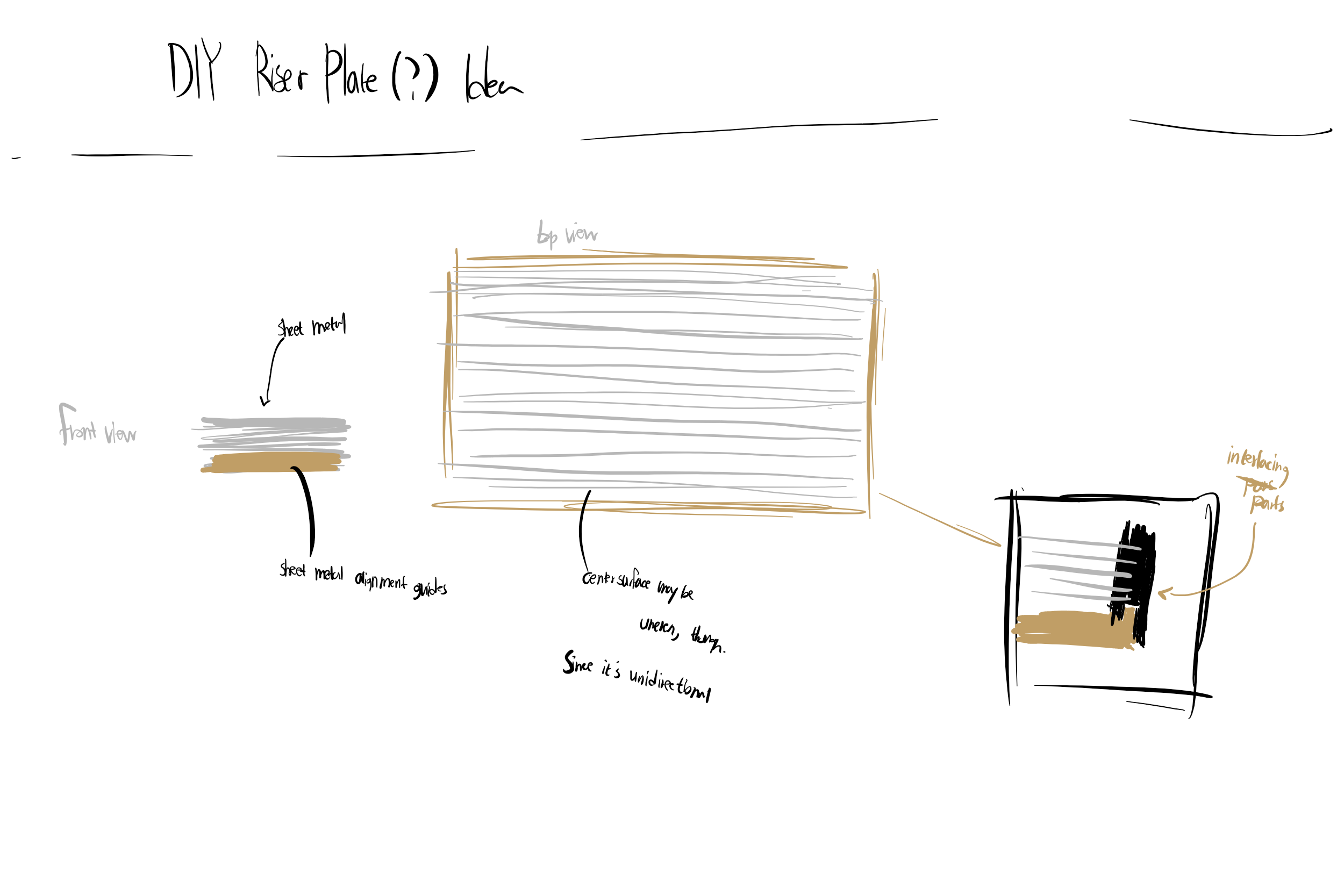

Constructing these things would be hard as well, since there would need to be cutouts for every intersecting spot on each fin.

However, if the metal fins are unidirectional and have no crossing, it should be easy to construct.

Also, a simple guide with cutouts to align the fins should make it easy to attach it to LCLC.

So that's the idea.

Typing this, I realized that a barbecue grill would prove itself to function well too. We'll have to see.

Jason Cho

Jason Cho

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.