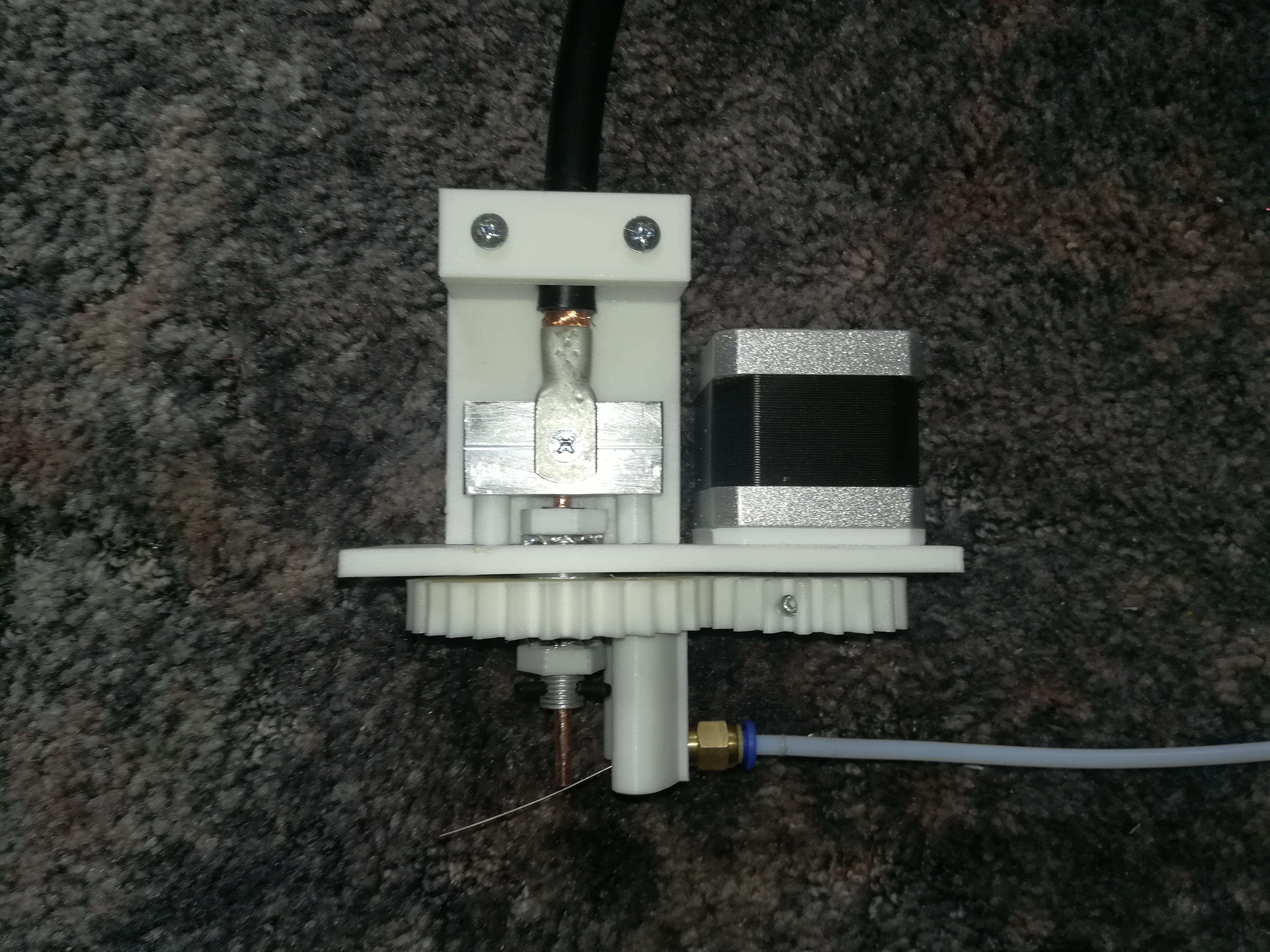

Here is a prototype of the wire bending & spotwelding toolhead.

The toolhead consists of a copper electrode in the center and a wire feeder which can rotate around the electrode to bend the wire in the moving direction.

There are still a few things to figure out:

- Using this kind of toolhead the machine will later have 5 axis (X, Y, Z, E and rotation) which requires software and firmware which supports it.

- The rotation axis needs an endstop, too. Maybe I could use a hall-effect sensor on the top plate and a magnet on the gear. Will test that the next days.

- There could be a problem with the bowden tube colliding with the gantry system.

- The wire is directed at the electrode, but if the electrode misses the wire the print can fail. Maybe a greater diameter electrode could help, but it could also increase the distance of two wires next to each other.

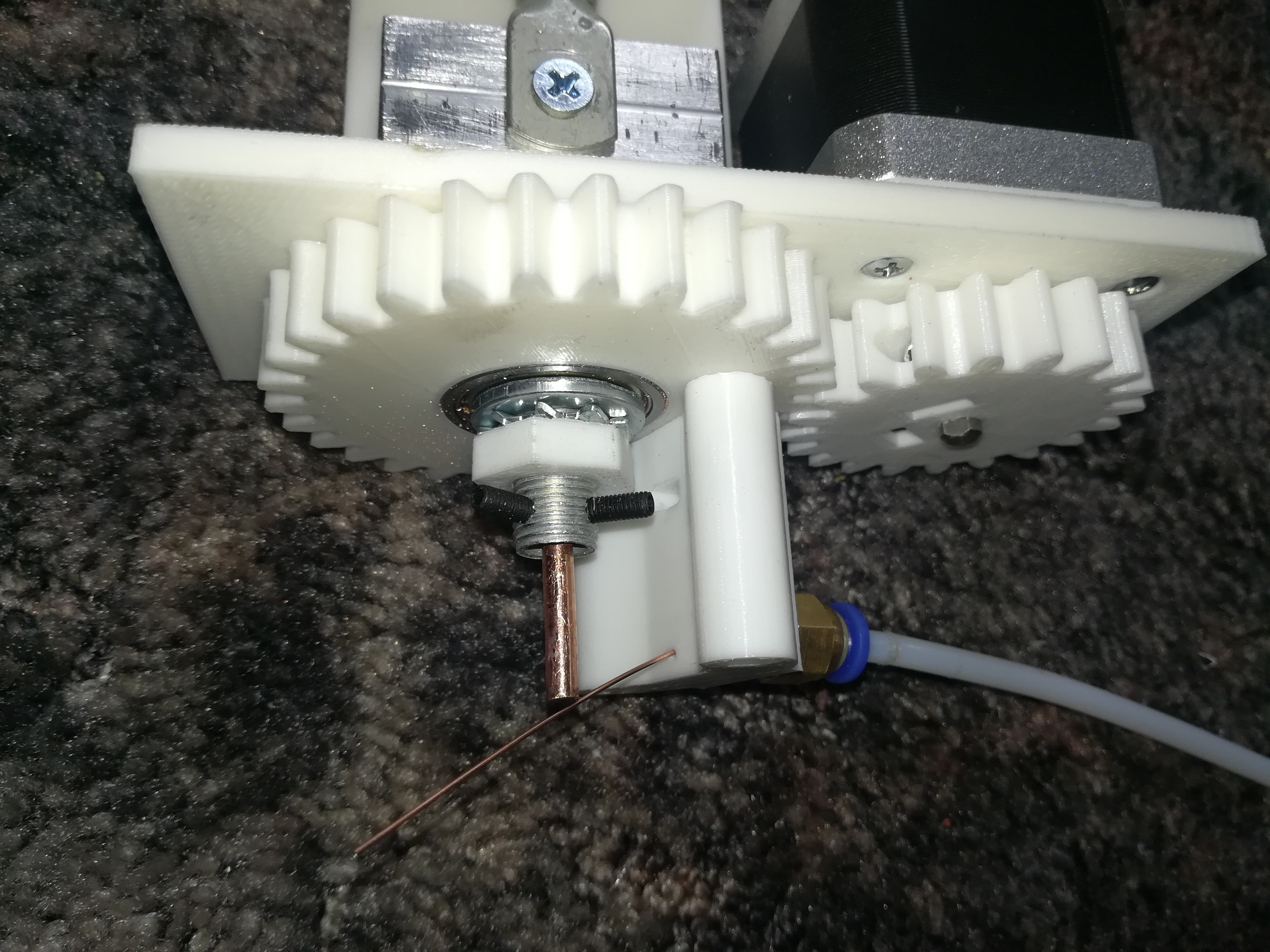

I addad a hall sensor to the toolhead to act as an endstop.

- Ordered a ∅6mm copper rod for using it as electrode, so that it's more likely that it will hit the wire.

The next step will be building the frame and finding a way in which the PTFE tube can move without colliding with the rest of the spot welder.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.