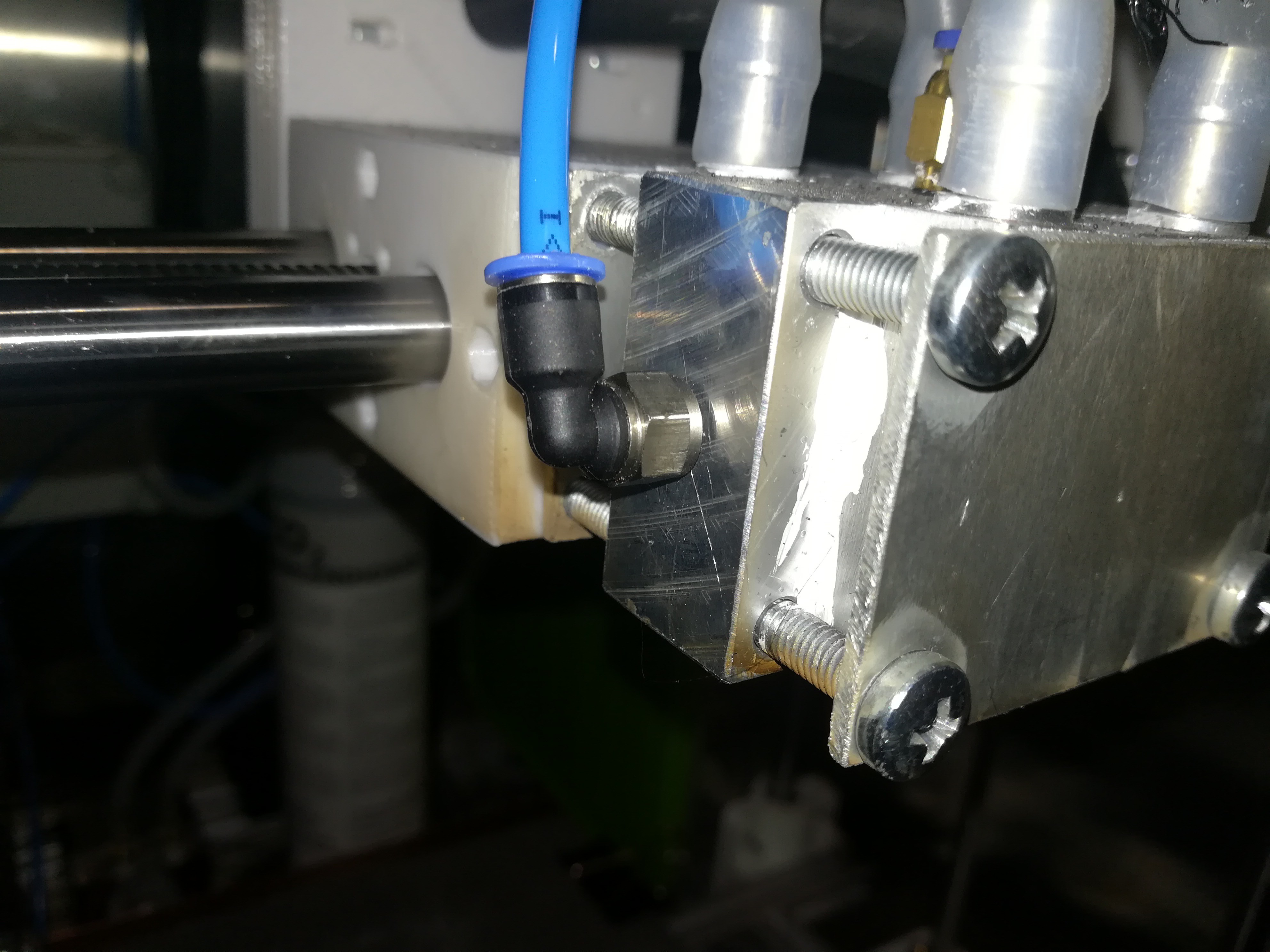

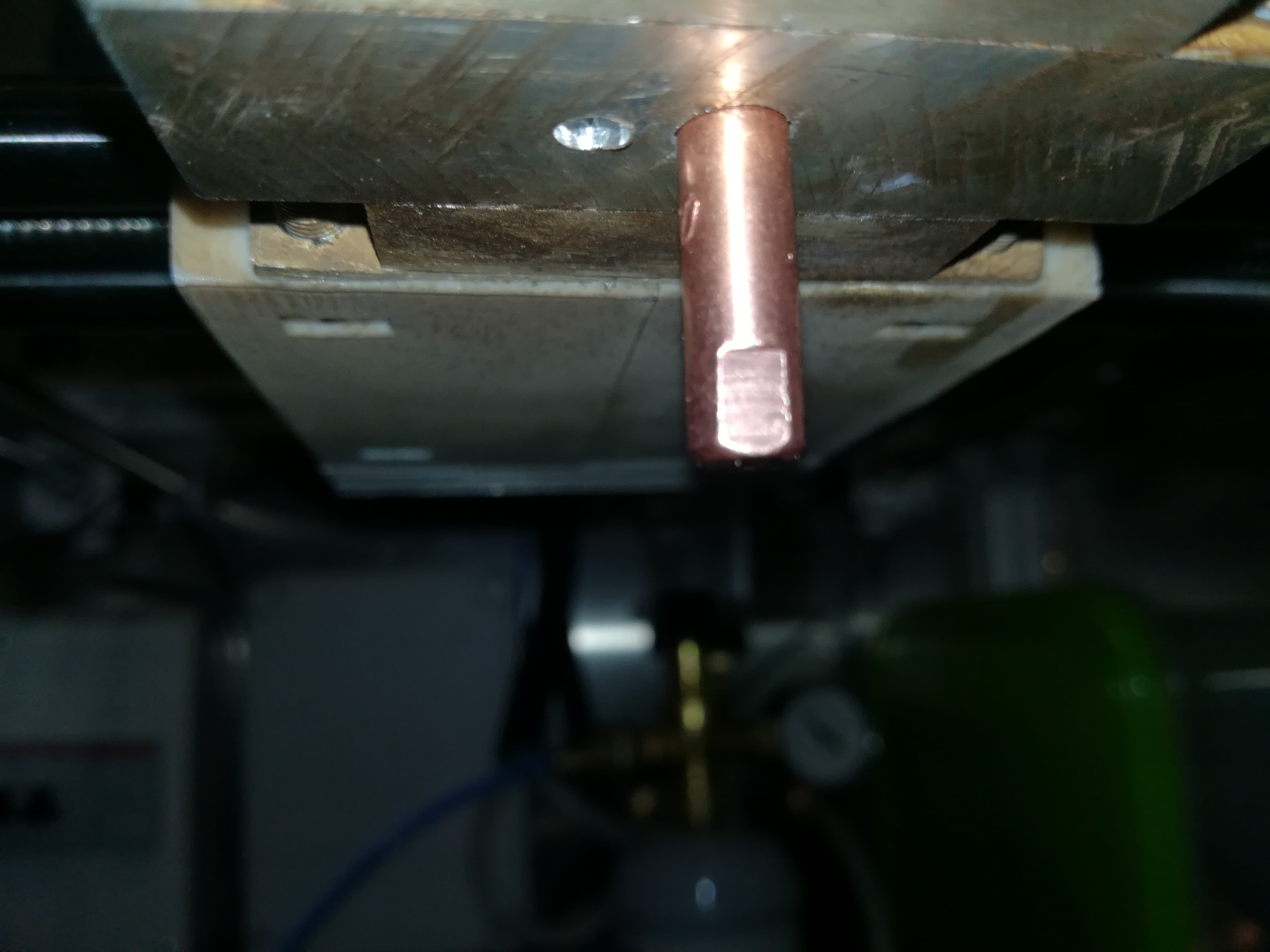

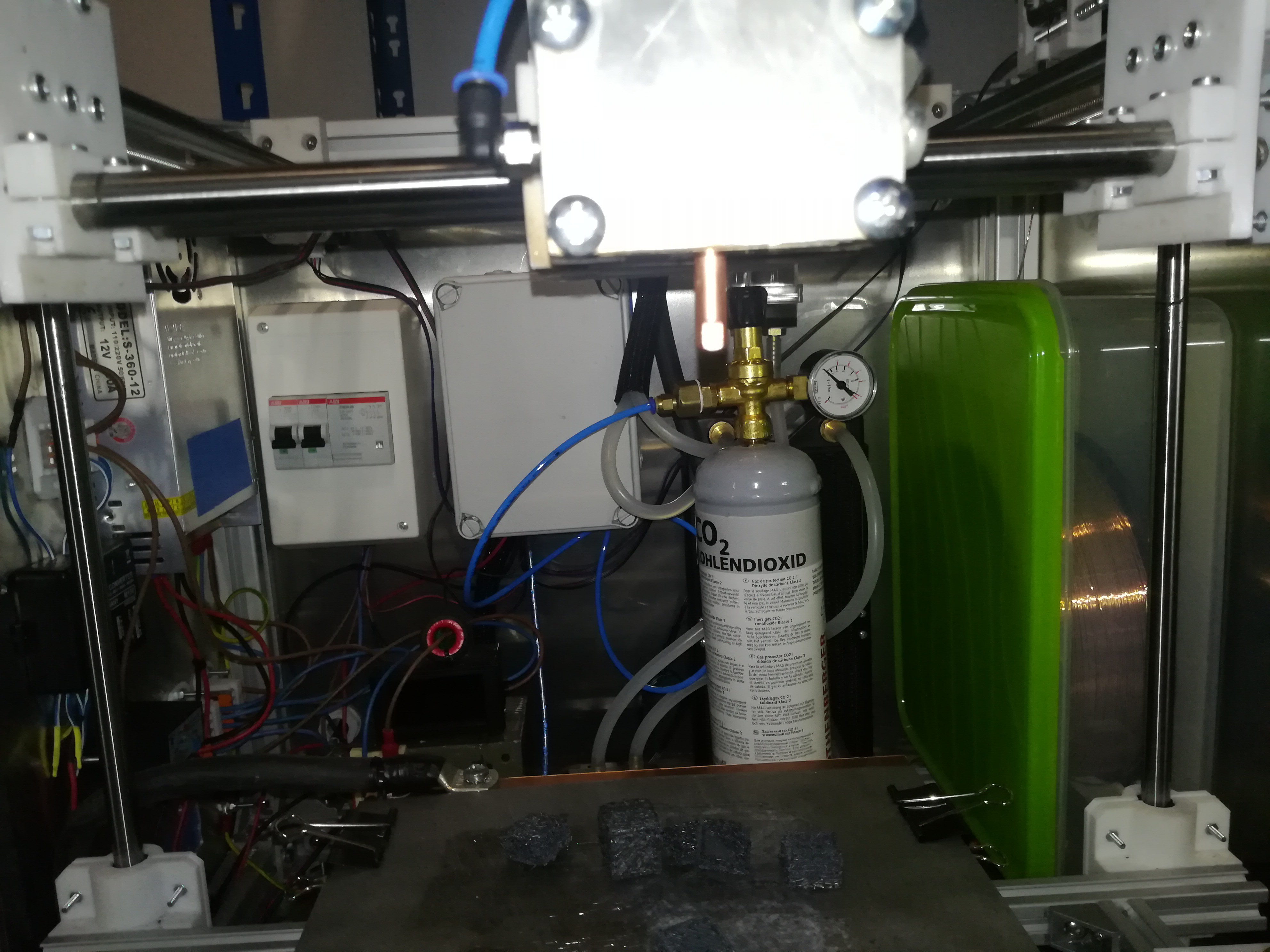

I retrofitted a shielding gas inlet to the printhead for more testing with shielding gas. At the moment it's just a hole next to the nozzle for spraying shielding gas on the buildplate and I'm not sure whether this is enough or whether I need a proper gas nozzle. I think I will see it while testing... I will also installed a solenoid valve for starting and stopping the gas supply.

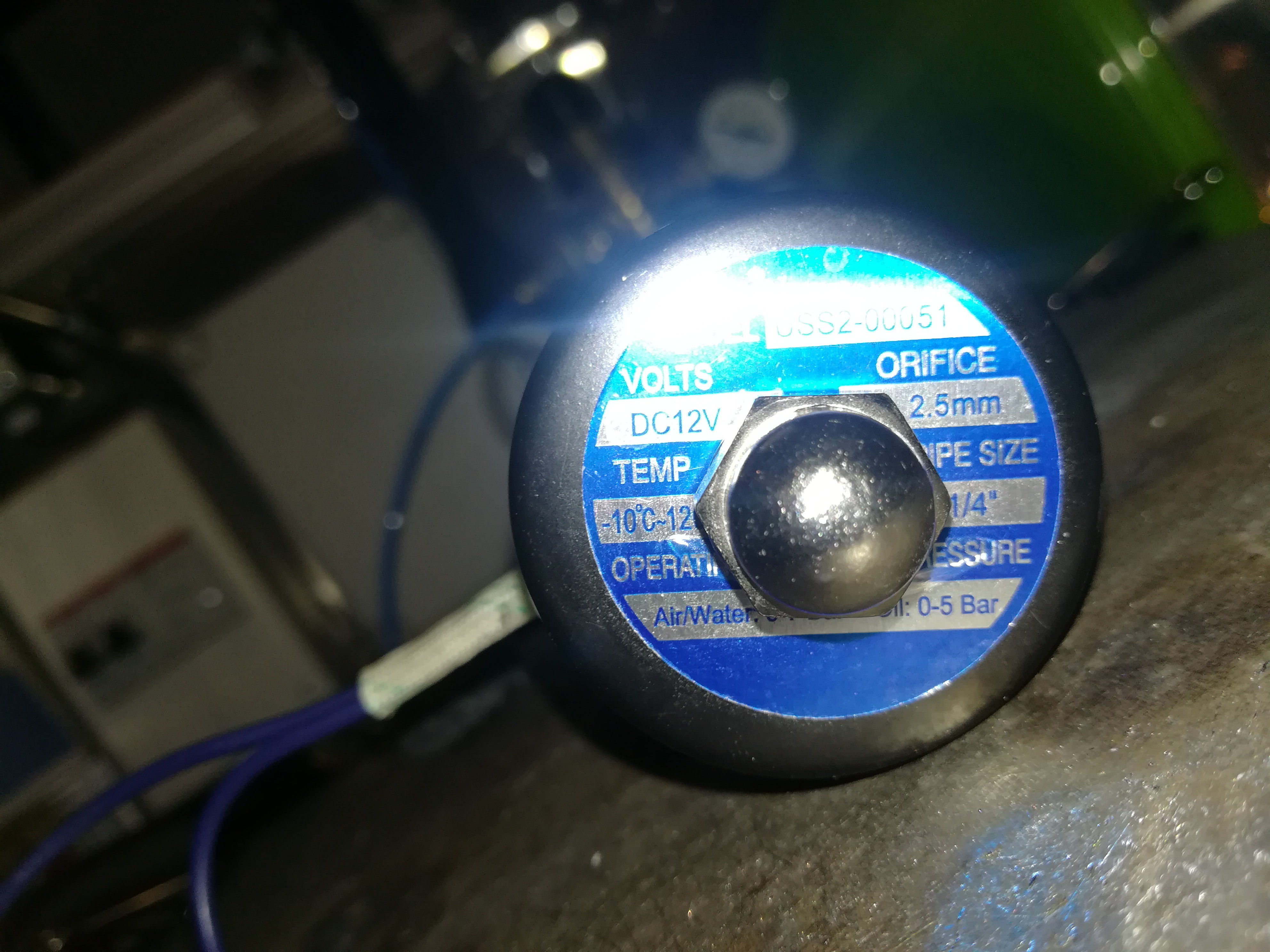

The valve can be opened in the startcode with e.g. M106 P1 S255 and closed in the endcode with M106 P1 S0. The valve I have works with 12V and so it would need a relay for operating it.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

I think that with hole in printhead AND closed chamber, you can start printing without first filling your chamber and after several seconds concentration of gas will be enough. Such simple hole in my opinion will not be enough for shielding, you should have some shroud/nozzle around electrode (and direct gasses sideways inside shroud), because that hole drags a lot of surrounding atmosphere and mixes it before hitting melting area.

Are you sure? yes | no

Hi, I ordered a TIG nozzle which already has the holes for shielding gas and a thread for a shroud to build a new toolhead with proper shielding gas supply.

I'm also planning to move the water cooling radiator underneat the Z axis assemby and add a polycarbonate front plate, so that the air stays inside the box.

At the former place of the radiator I then can mount the solenoid valve + relay to turn on and off the gas flow.

Are you sure? yes | no