-

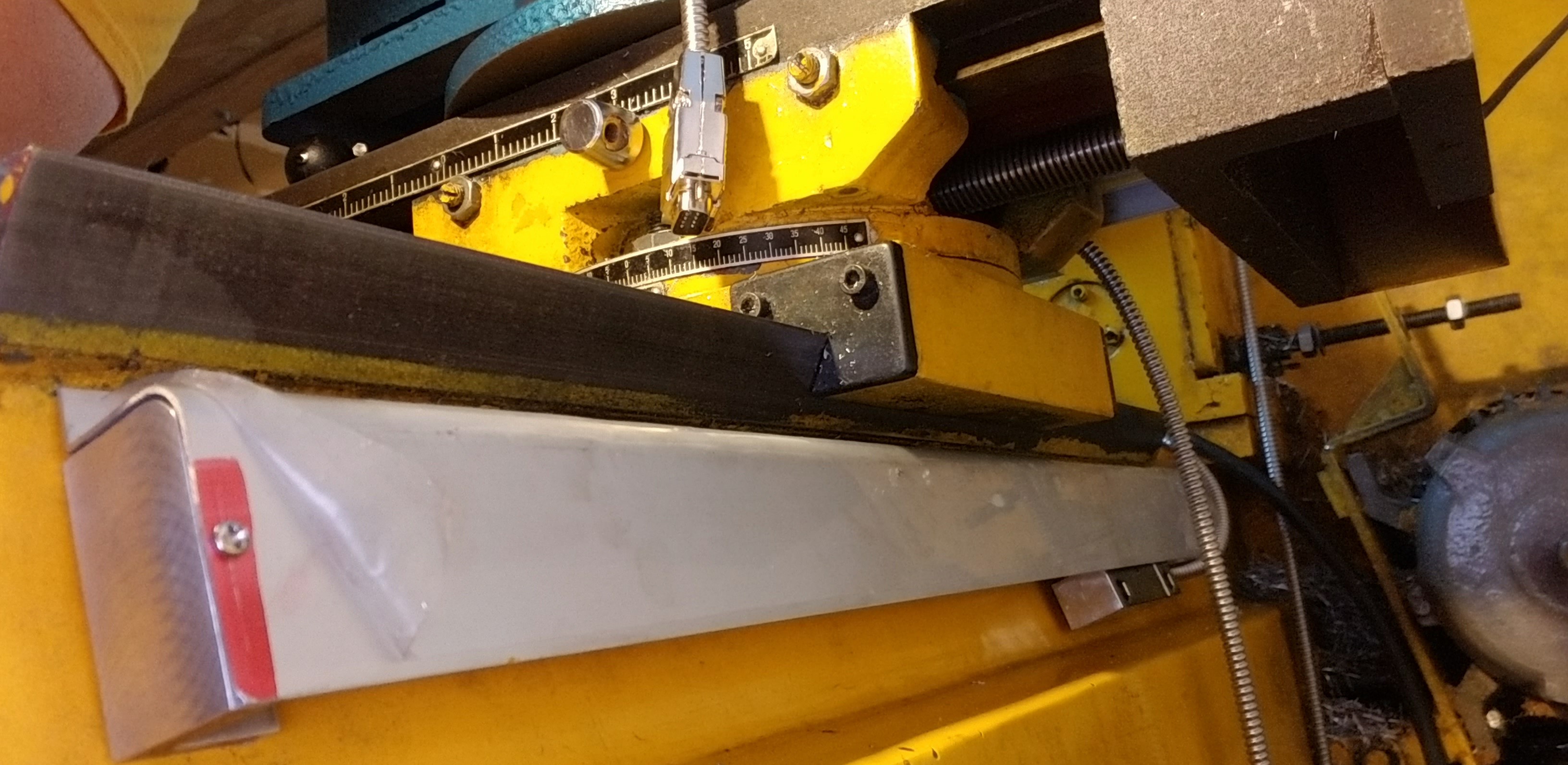

x-axis scale mount

04/23/2020 at 06:09 • 0 commentsThe casting is a little curved at the back, in the vertical axis, so the brackets might be twisting the scale a little and will need shimming.

![]()

-

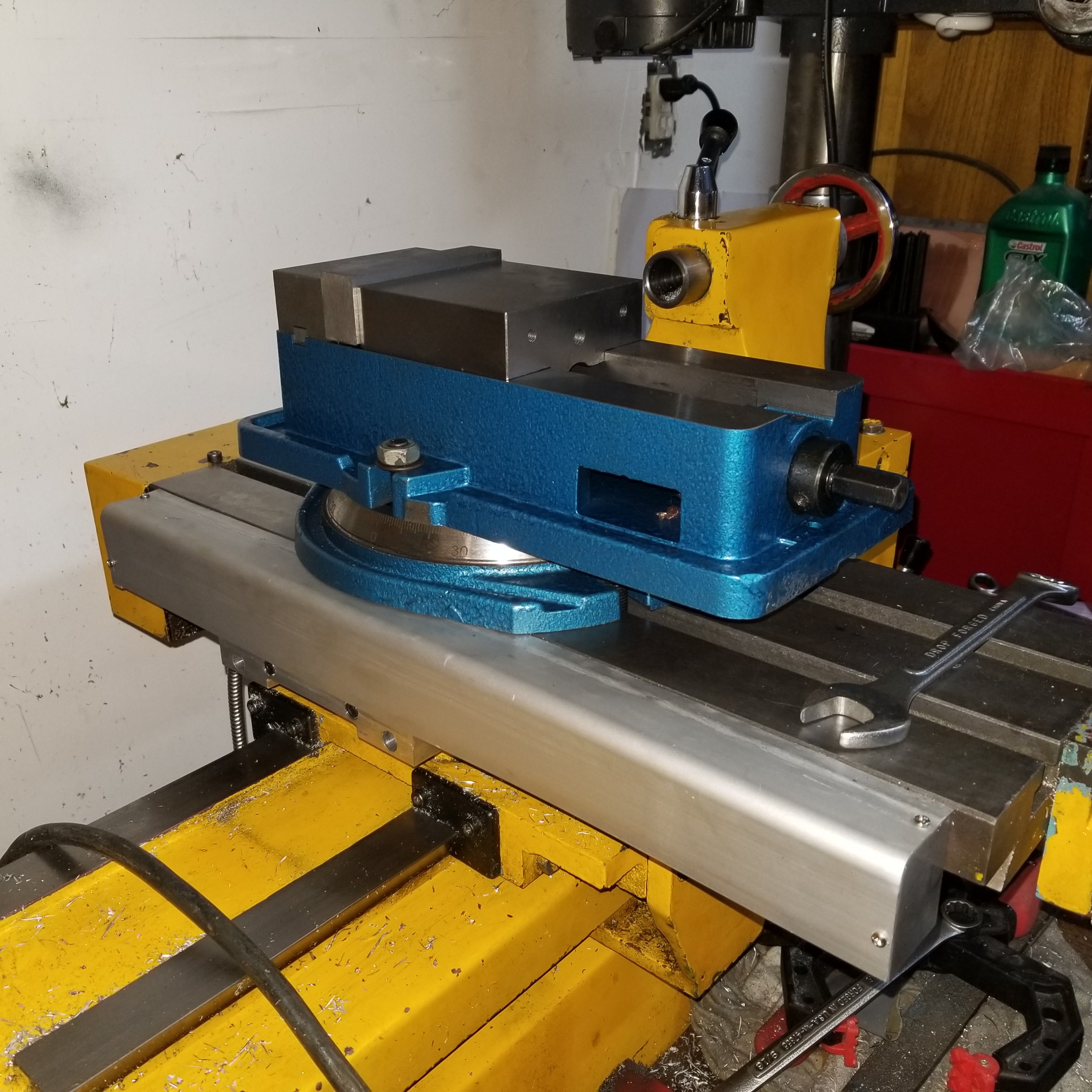

New Vice

03/29/2020 at 19:23 • 0 commentsUnder $100 and free shipping. 4" Kurt knock-off. No obvious manufacturing flaws other than the hex hole in the handle needs some relief. I haven't checked squareness or flatness yet, but the rigidity improvement is vast. Small cuts done to relieve some clearance at the bottom of the DRO end brackets.

![]()

-

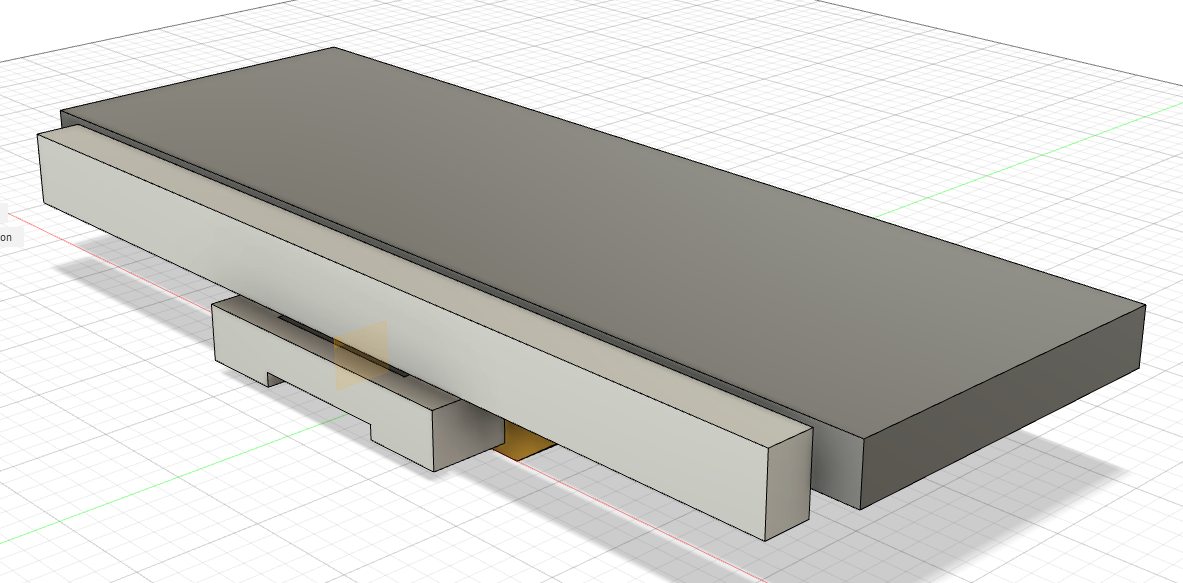

DRO Y axis complete

03/25/2020 at 02:36 • 0 commentsRough mounting showed the scale should be spaced out 3mm from the table to match the head below, so I made end brackets that act as spacers, end caps and cover supports.

Parts are mounted with 5mm screws that came with the scales. The cover is attached with 3mm screws from my electronics stuff. The top ones stand slightly proud but are so near the end of the table that I doubt they will hit anything. If they do, I can find some countersink ones.

The scales come with only one set of yellow dust covers but with slots for two so I bought 3m of the stuff on aliexpress and doubled them up. I think it is pretty well protected from flying debris. Some tape along the line between the table and the cover would be a good idea to keep out any fluids, but without a drip tray I'm not going to flood coolant any time soon.

![]()

![]()

![]()

![]()

-

Y axis scale rough mounted

03/17/2020 at 06:35 • 0 commentstaps and drill arrived from drillsandcutters.com and transfer punches from harbor freight. The y scale ia almost fitted. I need to make end brackets that will do:

- Space out the scale to line up with the head

- Close the ends of the cover

- Provide something to screw the cover to

The cover is 16mm longer than the scale and comes with a vertical lip to allow you to screw it to a flat surface. I bent/hammered that lip flat as the top of the cover will be flush with the table. This also makes it wide enough to reach out over the head bracket.

![]()

-

DRO Y axis head bracket done

03/08/2020 at 02:08 • 0 commentsOne of the scales arrived broken, so it is useful to use for checking fit without worrying too much about cleaning.

Mounting the scale should be straightforward now. I need a 2mm spacer between the table and the scale, and a cover. This could all be the same thing. I'll also need transfer punches and the appropriate tap drills and taps.

![]()

![]()

![]()

-

DRO Y axis progress and tool shopping

03/04/2020 at 05:12 • 0 commentsI've started work on the Y axis DRO mounts, using Fortal alloy (7075 T-651 from ebay seller scottkrez). This is a material I have used before and I know it machines well and can be made very shiny.

I'm on a learning curve with Fusion 360 and I'm on a relearning curve with the milling machine. The last time I used it in anger there were a lot less youtube channels on machining and I was doing a lot of things wrong. There are also some tricks for the Shoptask which I had forgotten. For instance my biggest mill is a 5/8" for which I purchased a 5/8" MT3 collet so it could mount up close to the head or in the 4" MT3 extension. What I forgot was that I really need a stop in the collet or the mill creep up in the collet vertically under heavier cuts. Properly tightening the mill column and the drawbar are also Good Things.

After some trial and error I have the piece down to 35mm in one dimension. The other dimension as to come down to 25mm from the current ~35mm. Lengthways was cut on the 4x6 bandsaw so that dimension does not need much taken off. I may try taking the 9mm of the face of the block with the bandsaw in vertical mode, though that thing is a bit scary.

The part I am making will mount to the base of the cross-slide and wrap around the DRO sensor head to use the side mounting screws. I would rather have made it slimmer and support from underneath, but that would block access to one of the nuts that tightens the table rotation. The scale and head will be 2mm out from the base though I may skim that down a bit depending on what material I use to run behind the scale. As the scale overlaps the base somewhat some clearance is needed.

I have ordered some parallels for the vice, as for cutting the channels into the part it will have to sit up high. The first time round with this machine I didn't even know what parallels were and I managed with random stuff. The best I have at the moment is to use dies. As these are ground I was able to find a couple of matching thickness to do the job for now. The vice I have is a tilting angle vise that I bought with the machine that looks very like this: https://www.hhip.com/4-deluxe-tilting-angle-vise-3900-2684.html

This has to be set up on two 1-2-3 blocks on the "2" side to raise it high enough, and setting the tilt to properly horizontal is a pain., and I'm pretty sure it lacks some rigidity.

So the next thing on the shopping list is a 4" mill vise of the Chinesium-Kurt-Knockoff variety, along with the swivel base. I think this will be nice and high and by mounting the swivel base at an angle I should be able to my two (narrowly spaced) T-slots and get it centered on the table the "normal" way round.

Also purchased is a used Starrett S828H wiggler set for $25.

Reviving a Shoptask 1720 XMTC Gold 3-in-1

This thought project is notes on reviving my 1998 Shoptask 1720 XMTC Gold late-mill-drill

Alastair Young

Alastair Young