-

Extruder choices

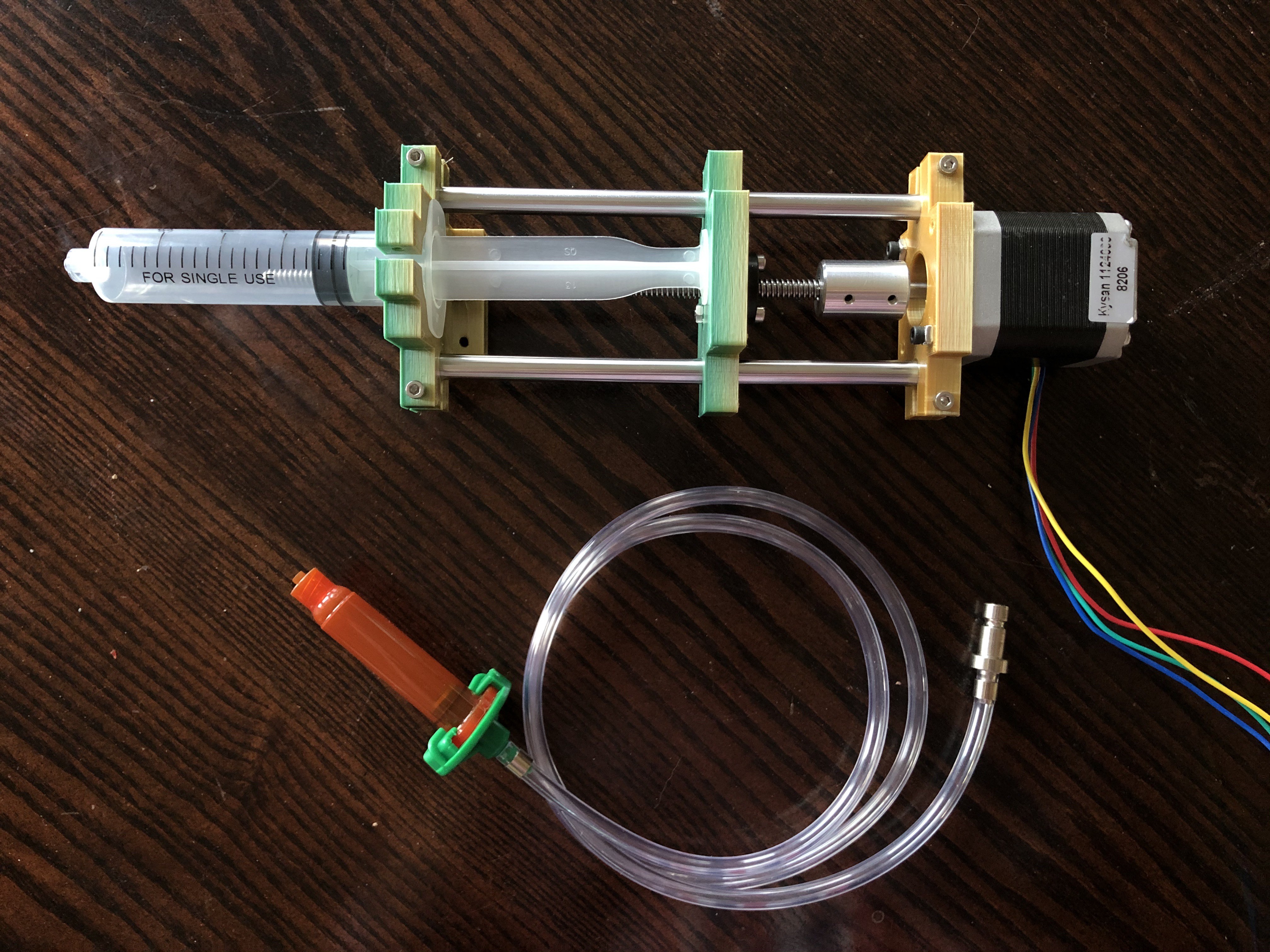

03/04/2020 at 21:30 • 0 commentsI've looked at a few choices for the extruder, the one I built first isn't going to work. Looks like I'm going to need the syringe to be held in place better, this design seems to be better for less precise designs, maybe for larger volumes that don't have to be as precise.

Ystruder - looks promising, but a little more than I need, includes a force sensor and control electronics. Might do this later on if I need feedback on the pressure

https://www.sciencedirect.com/science/article/pii/S2468067219300471

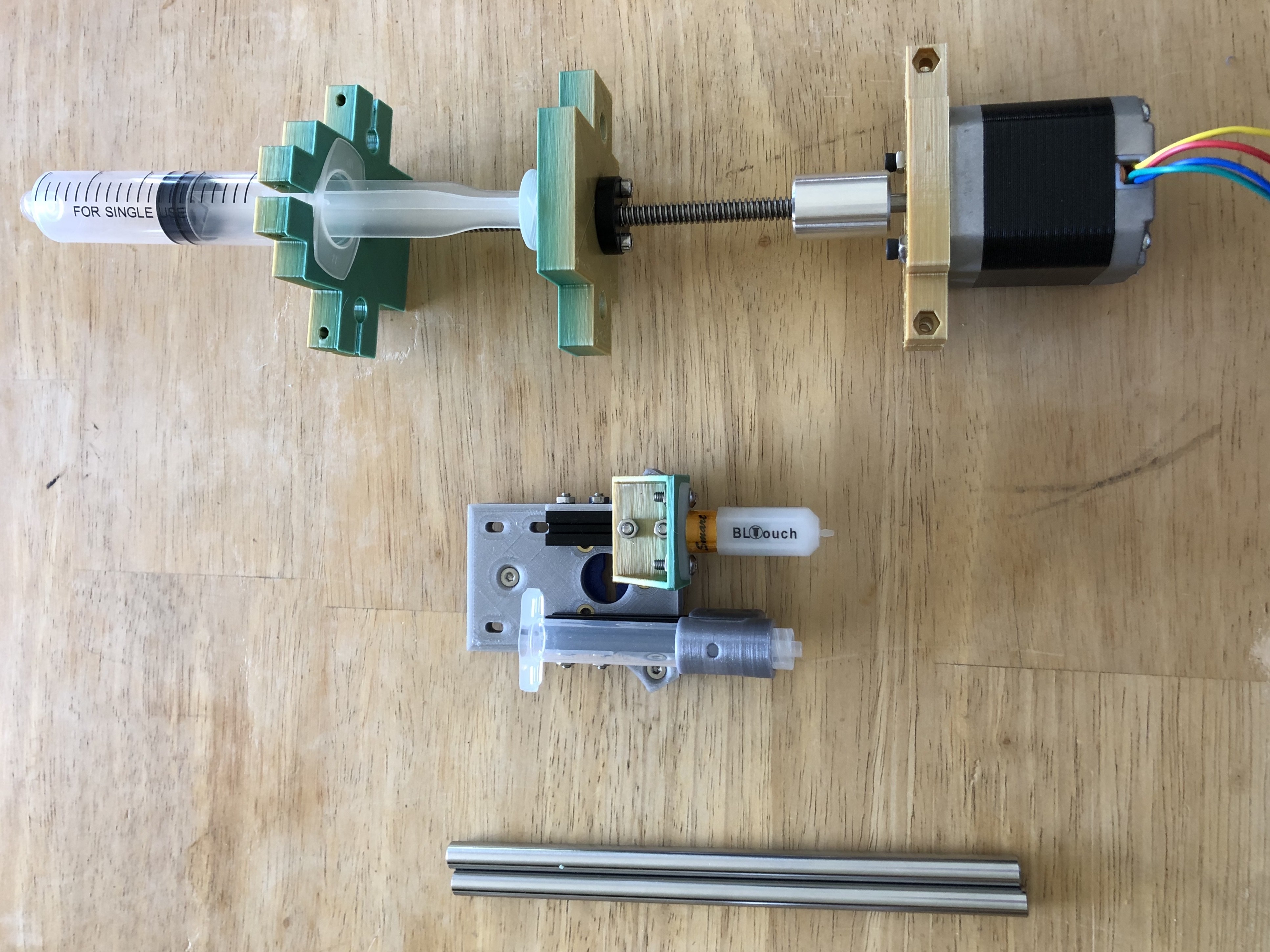

Open source syringe pump - I've printed a few parts to this one already but they aren't quite exact enough so I"ll need to adjust the designs and reprint. I like that it supports different syringe volumes.

https://www.appropedia.org/Open-source_syringe_pump

Also bought a pneumatic solenoid valve that I'm going to test, it's the most similar to systems I've used before. Should be able to handle the highest viscosity fluids in my experience. Might be a little harder to integrate into an existing print workflow, and also requires a pump so it's not as cheap.

https://www.amazon.com/gp/product/B07SJFV7S3/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

Any suggestions from the community? Previous similar projects that used precision syringe extrusion?

-

Mechanical designs v1 finished

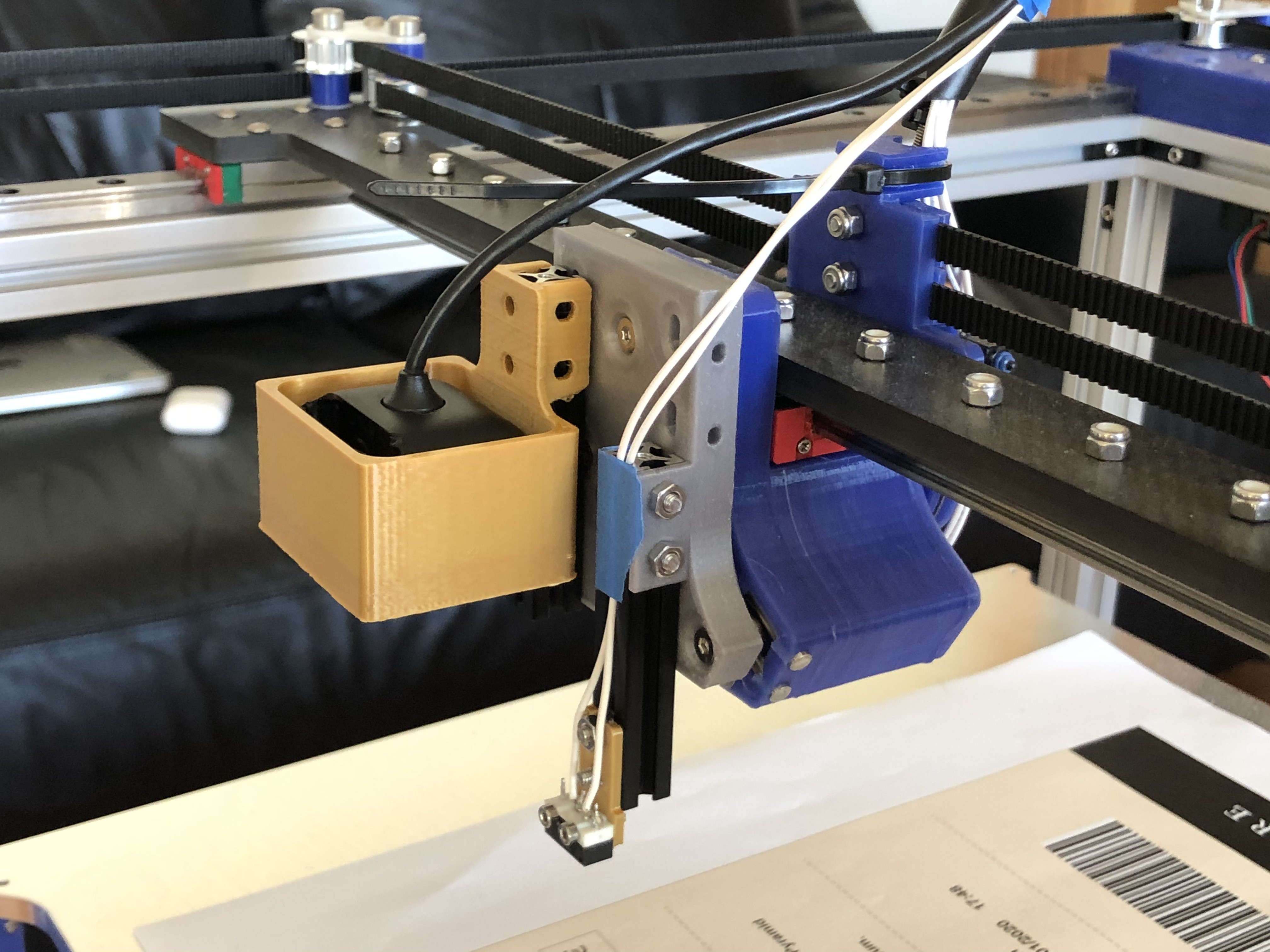

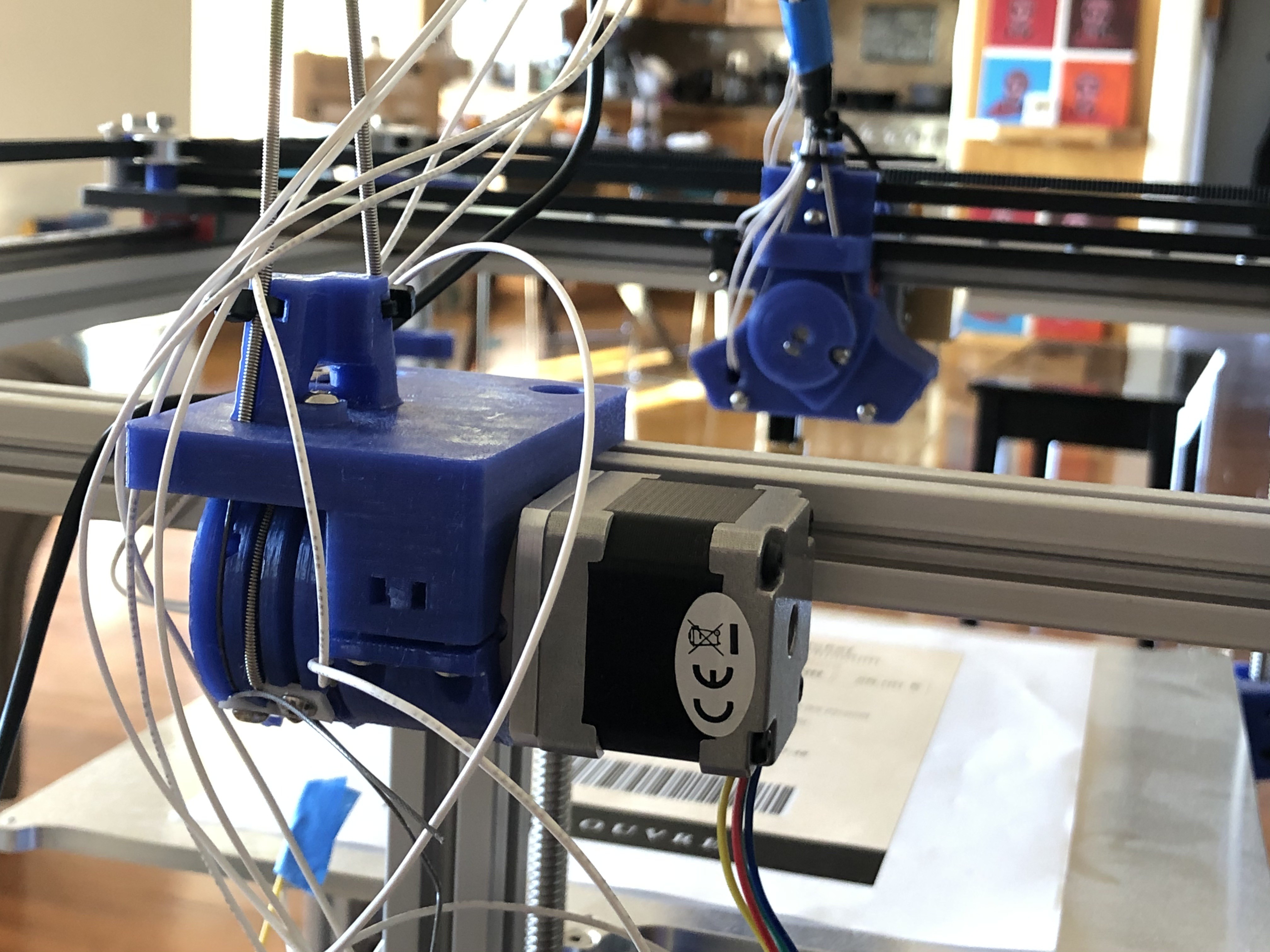

03/02/2020 at 05:18 • 0 commentsI have the XYZ motors working and have assembled the toolchanger. Also designed a mount for a webcam and got the camera to show video on the Jetson Nano

![]()

The toolchanger still doesn't have the required torque when fully tightened, so I am modifiying the toolchanger v-lock part

![]()

I also assembled an extruder, but the current design doesn't support reverse pressure which could be an issue

![]()

Multi-tool circuit printer

An open source circuit board printer based on the Jubilee multihead motion platform