Watched a few you tube videos to get an idea what some people have tried.

No use re-inventing the wheel. Simplest solution I could find is the guy with the reptile mat of course.

Here's what I found to make this happen:

1. Old AC cord from wherever.

2. Plastic container. 25L? Something like that.

3. Two aluminum trays from an old toaster oven.

4. Old baby bottle warmer heater element.

5. Normally closed Bi-metal switch. I think this came from an old microwave at some point.

6. Gland for wire to go through box.

7. Two 220VAC industrial fans.

8. Fuseholder and 3A fuse.

Since both the heater element and fans could take AC voltage, and the bi-metal switch was rated for 240VAC there was no need to build any kind of power supply. I tested the fans and they spun up at 110VAC as well (about half-speed). This was great for air circulation.

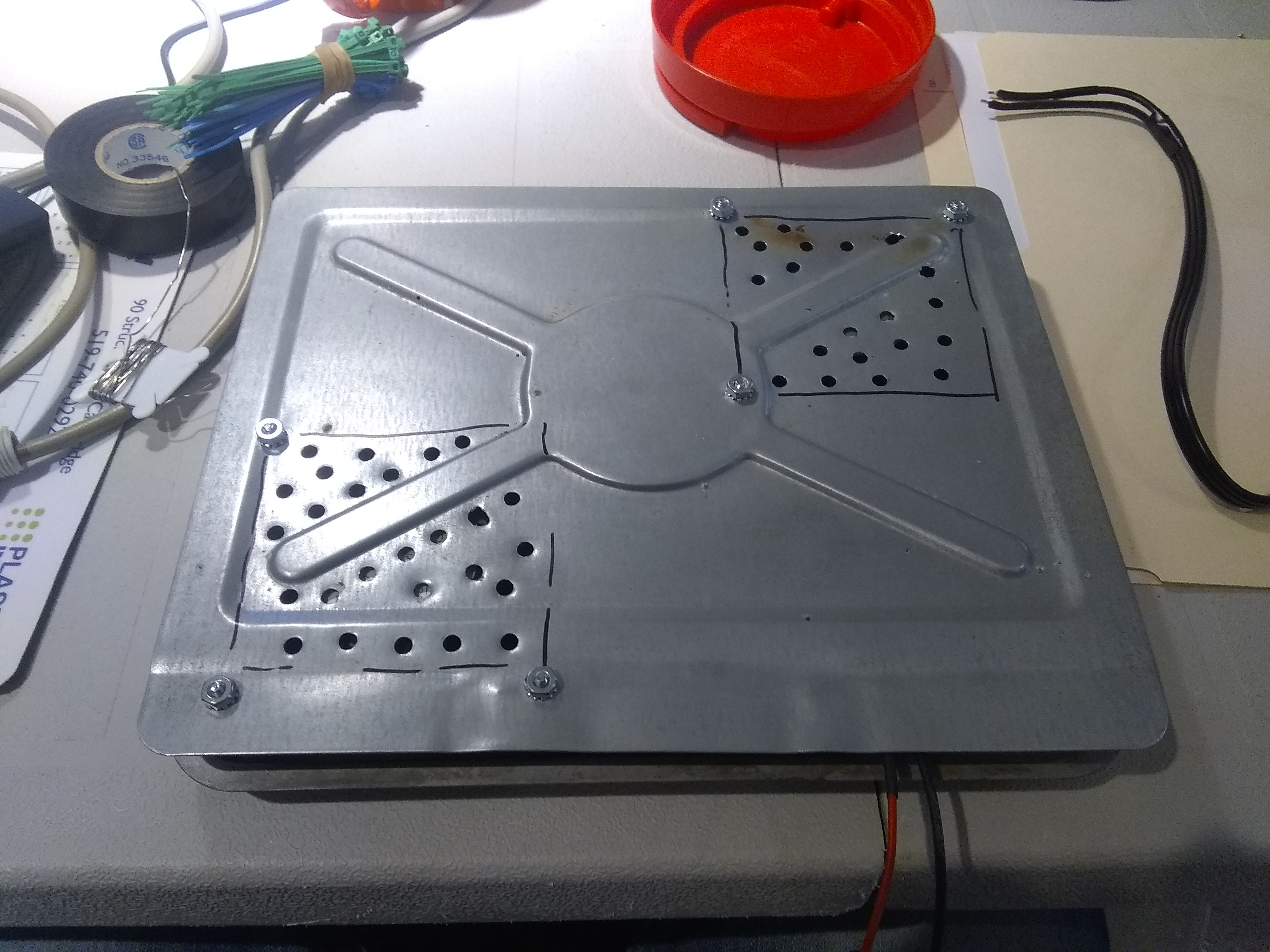

Bolted the fans up to the bigger tray tray using a few washers so the rotor doesn't rub on the bottom.

Installed the heater element in the middle.

Connected the fans together and directly to 110VAC.

Bolted bi-metal switch to the heater. Wired heater and bi-metal element (in series) to 110VAC.

The idea here is that the element will get to 50C and the bi-metal switch will open and stop the heating process. The heating element heats up VERY fast at 110VAC so it will be on for very short periods of time. This will allow small amounts of heat to be built in bursts inside the enclosure, reaching an equilibrium with the natural losses of the box. Regardless of these losses, the temperature that the system will settle at will be significantly below 50C. That temperature should be acceptable for PLA storage. This is determined experimentally and may vary by container size and degree of sealing of lid.

This is all good but we will need a fuse, for at least a modicum of safety. I was surprised that the 3A fuse that I had on hand didn't burn up immediately with that heater element. It seemed like a value that would verge on the low side for this setup so I just kept it. I installed the fuse in series on the phase ("hot") side of the AC coming from the plug. This way we would lose the phase if the fuse went. This would definitely stop everything cold.

Perforated the other tray to make a shield with ventilation holes where the fans were. This tray was aluminum too. It would shield the filament from the intense but short burst of heat coming from the heating element. It would act as an averaging buffer for these bursts. The space in between the two plates is a welcome addition since this will provide additional paths for the warm air currents.

TheGrim

TheGrim

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.