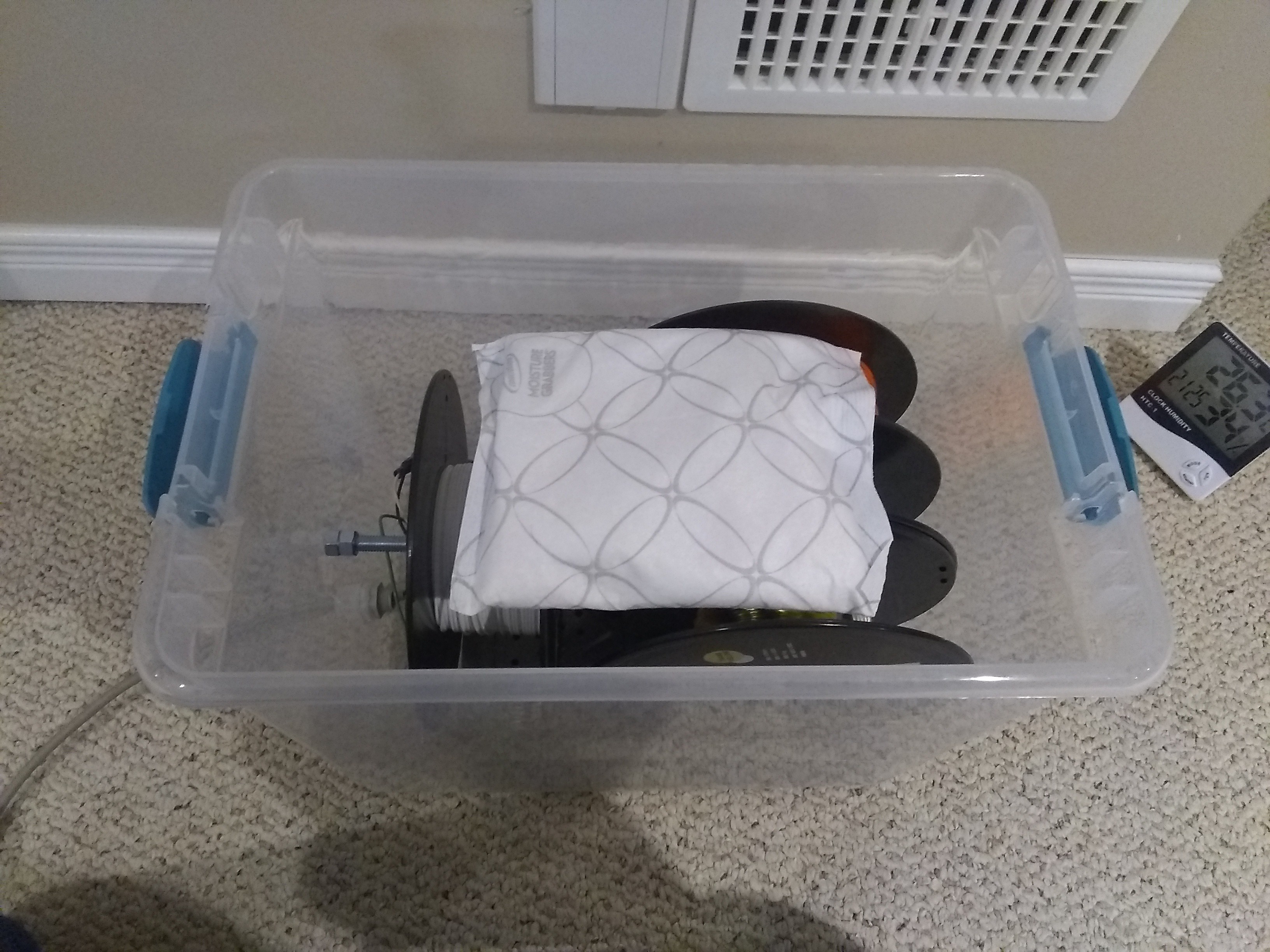

Now, being satisfied that nothing will melt into a ball of ooze, it's time to put the filament in. Dropped a few rolls in (not my best ones) and plugged it in. On top of the rolls I added a desiccant pack from the hardware store. They are usually sold for reducing humidity in camper trailers (during storage season) and boats. Cost for this was around $4.

I put the lid on and plugged it in. We'll see how it does.

A check a couple of hours later, it was sitting a 28C and 32%RH.

I will provide an update at a later date on the long-term efficiency of this unit.

Some drawbacks at first glance:

1. The strange humming of constantly running fans.

2. Not grade-A electrical safety to do things like this.

3. The bi-metal switch has a limited number of cycles before it fails.

4. I would not leave this plugged in if I wasn't around.

Improvement ideas for next iteration:

1. Replace bi-metal switch with TRIAC.

2. Integrate a safety relay to stop a thermal run-away.

3. Control the heat and safety of the system with an Arduino.

TheGrim

TheGrim

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.