The good news is the first one is built and working. Actually, 2 units.

The bad news is, the SFM3300 has gone into scarce supply and can't be had.

But, much can be learned with these units while other projects that don't rely on this sensor can be developed.

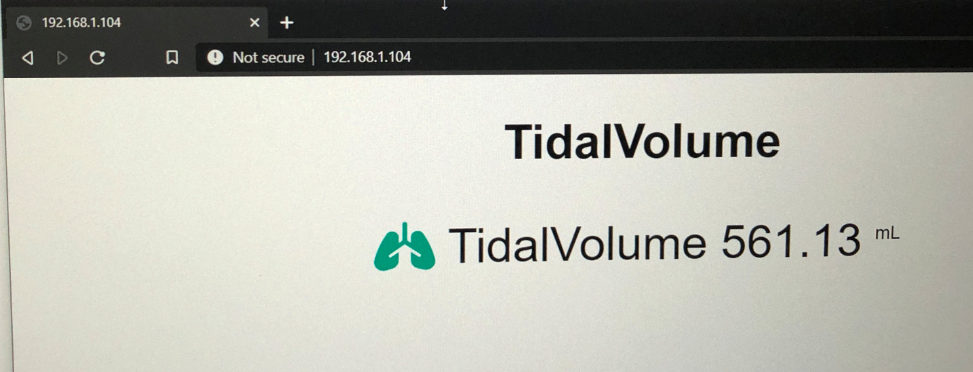

Here is the 1st working unit. Breathing into the flow sensor, it calculates the tidal volume (volume of inspiratory flow on a single breath). I also display the time since last breath in seconds, this will later drive an alarm if this goes beyond 6 seconds (respiratory rate should be about 12-20 breaths per minute).

Since we're using an ESP32, web page shows the same data.

Missing on this unit are some must-haves

- Pressure

- PEEP (Positive end-expiratory pressure)- which is the minimum pressure, monitored and controlled so you don't get lung collapse

- PIP - (peak inspiratory pressure) - monitored to make sure you don't exceed 28 cmH2O

- Tidal Volume set point or range

- Tidal volume (TV) is usually set to 6-8mL/kg PBW (predicted body weight), see table

- Alarms

- Device should have audible & visible alarm when the following occurs

- TV is out of acceptable range (range tbd)

- TV goes to zero (hose disconnect)

- PEEP or PIP pressure beyond safe limits

- Device should have audible & visible alarm when the following occurs

Features/issues of this design approach

- Power

- POE Power (not used in medical environments?)

- USB 5V Power (connector is not positive locking)

- Battery backup (only for 3.3V, sensor requires 5.0V)

- Connectivity

- Additional RS232 port for debugging/monitoring

- Allows USB port to be used for serial plotter

- Remote monitoring over WiFi (requires WiFi access point setup)

- Remote monitoring over Ethernet (networking challenges)

- Additional RS232 port for debugging/monitoring

- Sensor

- This sensor is expensive and is not currently available

Still lots of work to do. Also, there are individuals working on implementing parallel designs, versions using hot wire anemometer, everything from an automotive mass airflow sensor to a transistor based unit. At some point, the prevailing unit (ideally 3.3V powered for my design direction) will be adapted to this design so we can make more. We also have a couple of designs in progress that are based on differential pressure, one with a pitot design and one as a venturi design.

Most are using an existing PCB, from STM Blue Pills, ESP32s, Arduino, & feathers. Also, one design is going component level using a STM32.

The current plan with these 2 sensors is to do some testing, with simulated lungs. Hopefully in the next couple of days, in a med-school lung lab.

We are looking at what this will take to get FDA EAU approval under the PREP act. This will provide liability immunity.

Patrick

Patrick

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.