I did a single material test run and it worked quite good until the material "got stuck" in the supply line.

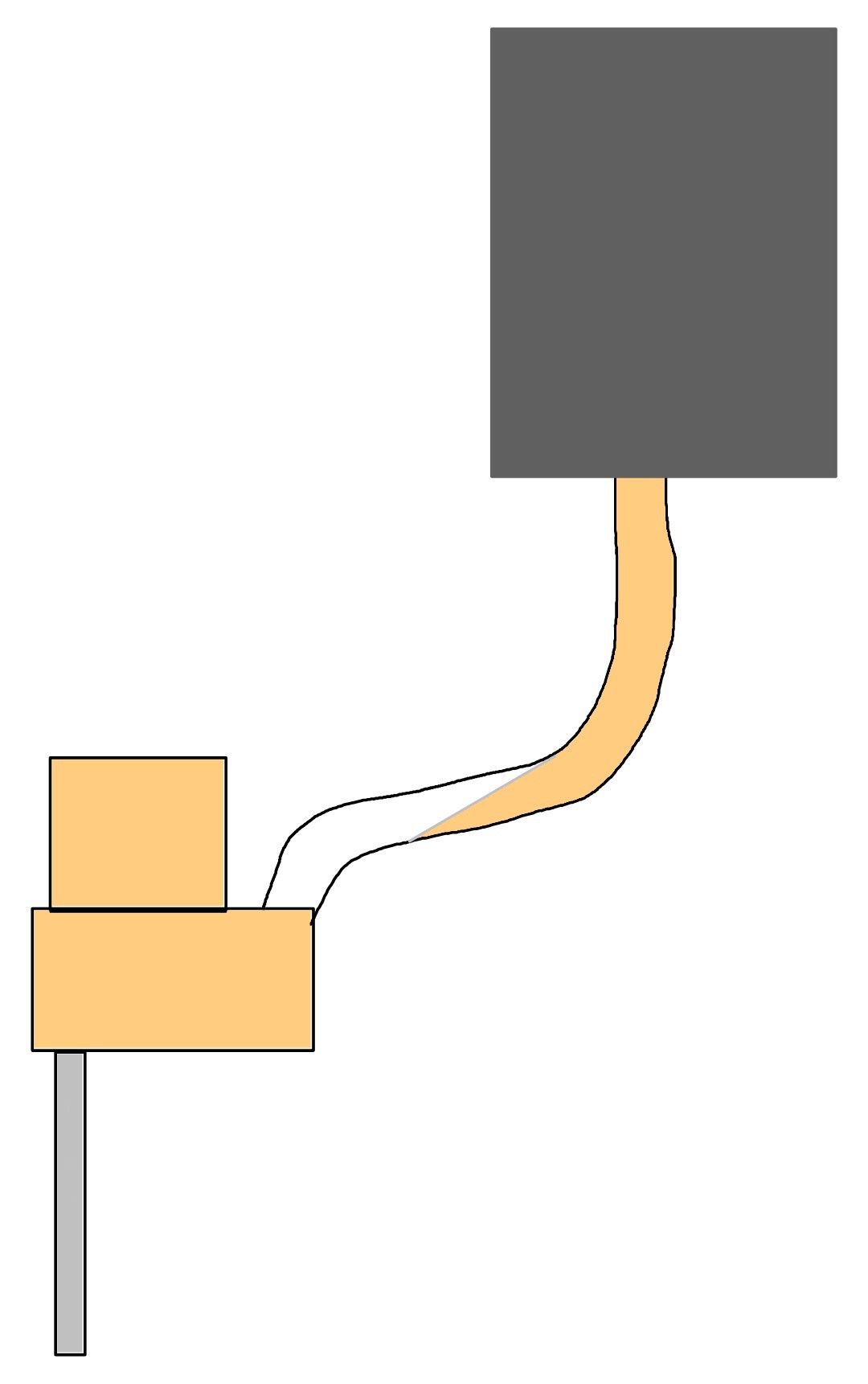

That happened because with the Z axis rising the supply tubes got bend and the material didn't longer fell into the printhead.

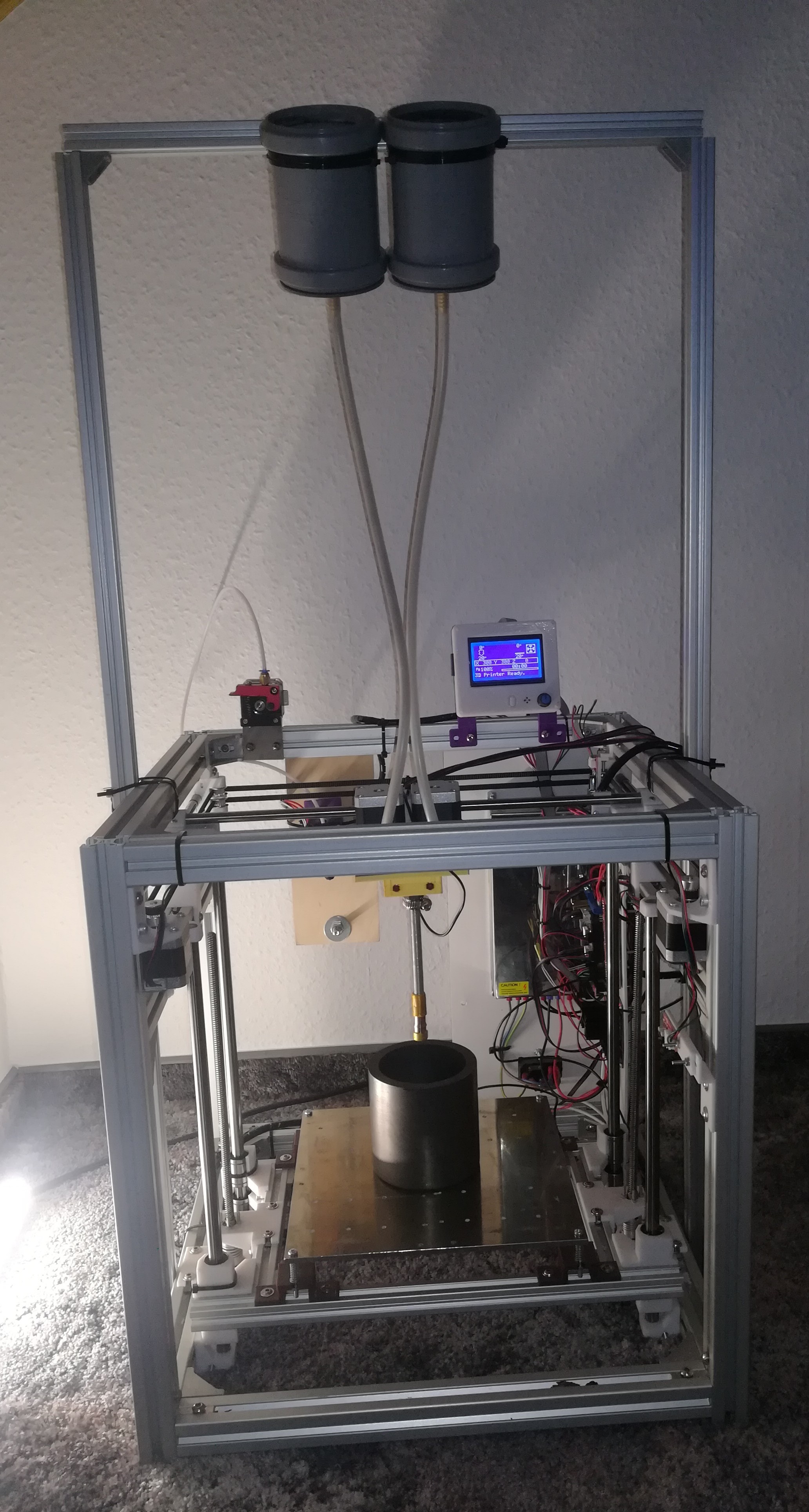

So I mounted the toolhead on another printer and added a frame with the material containers high above the printhead, so that the material can fall straight down into the printhead in any position.

Because of the G38 bug the endstops.cpp has to be edited to get it to work with a CoreXY printer.

In the file there are two lines from which

!(CORE_IS_XY)

has to be deleted.

The design with the material containers mounted high above works very reliable. I tested printing for several hours and never had problems with it again.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.