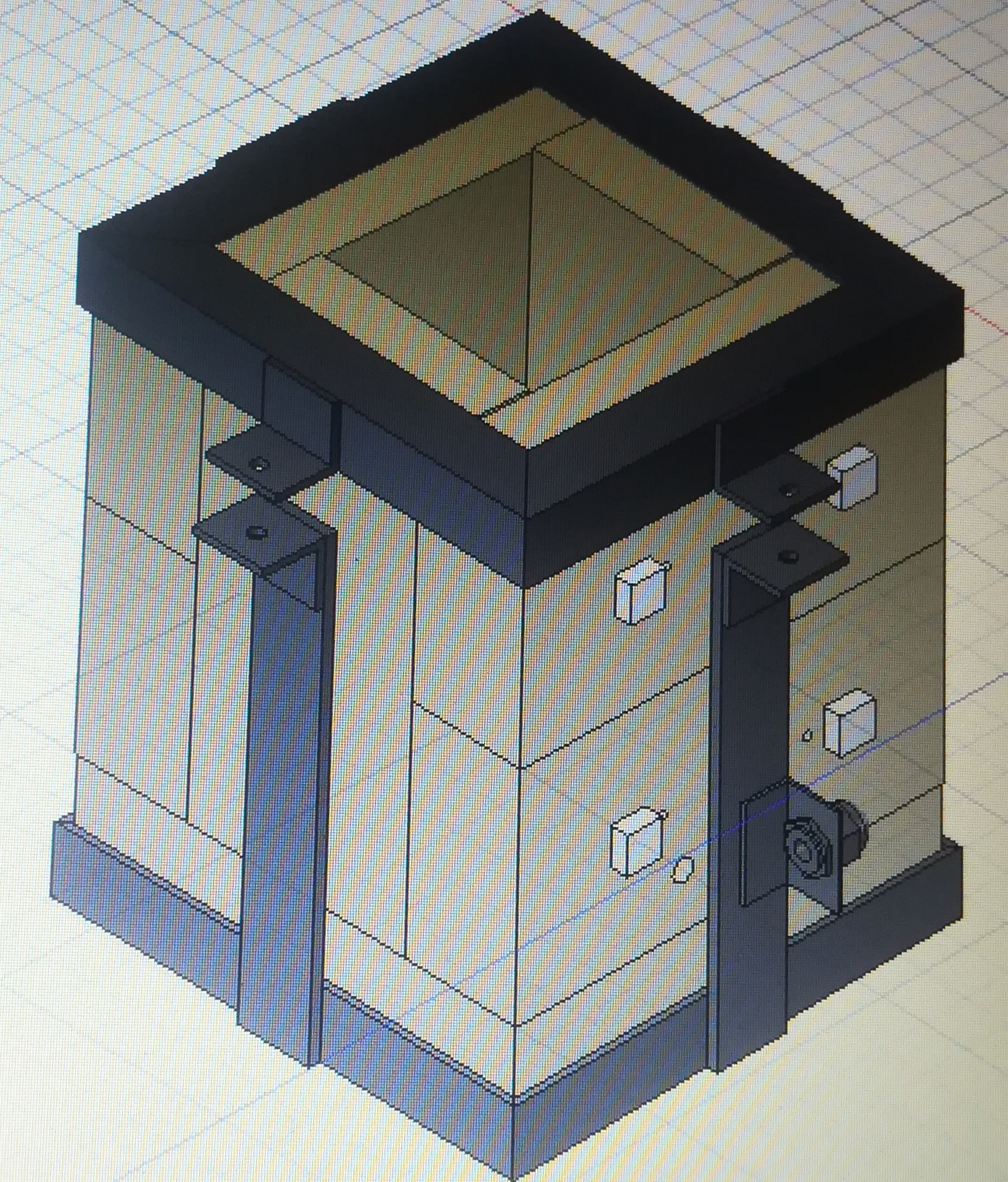

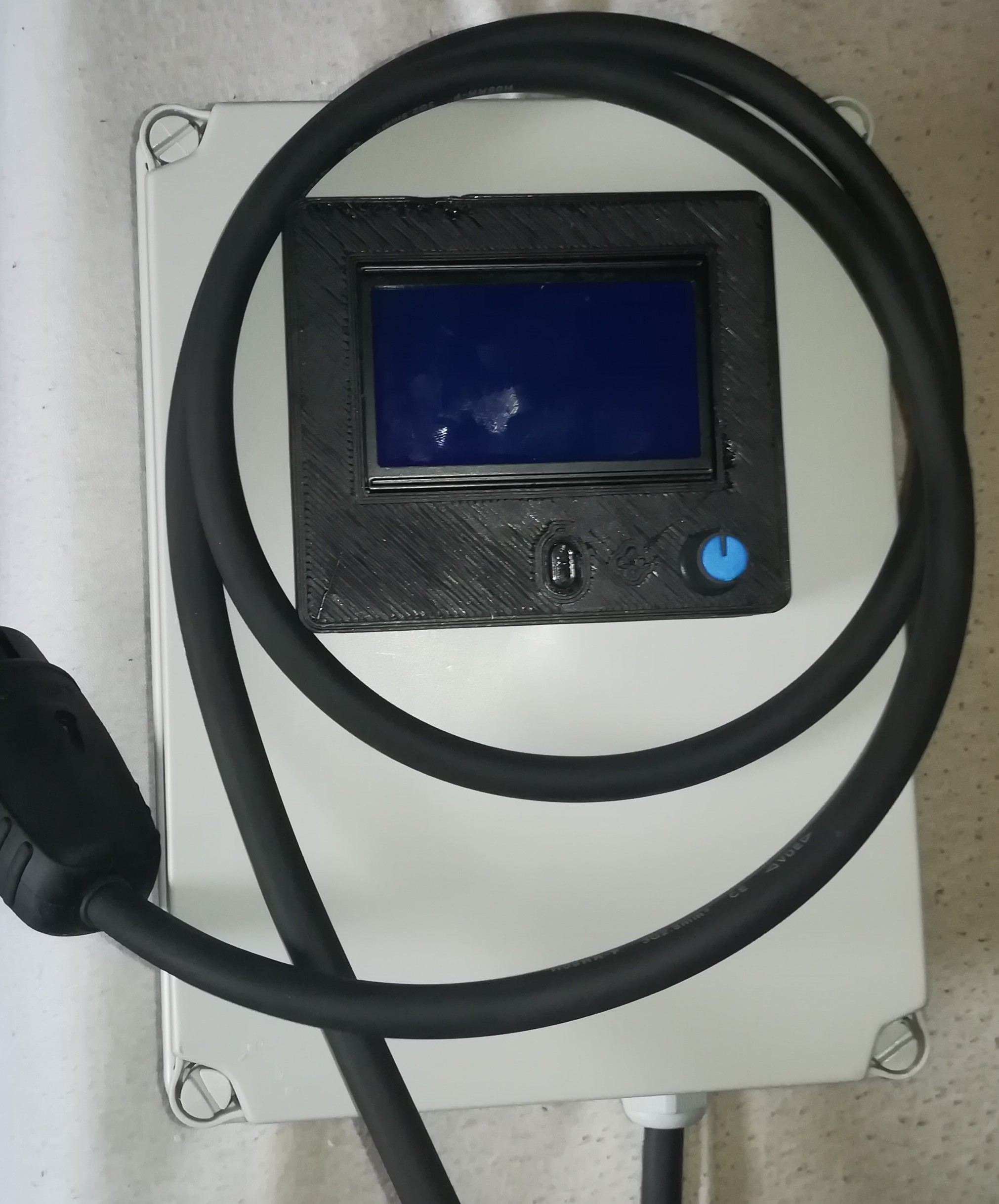

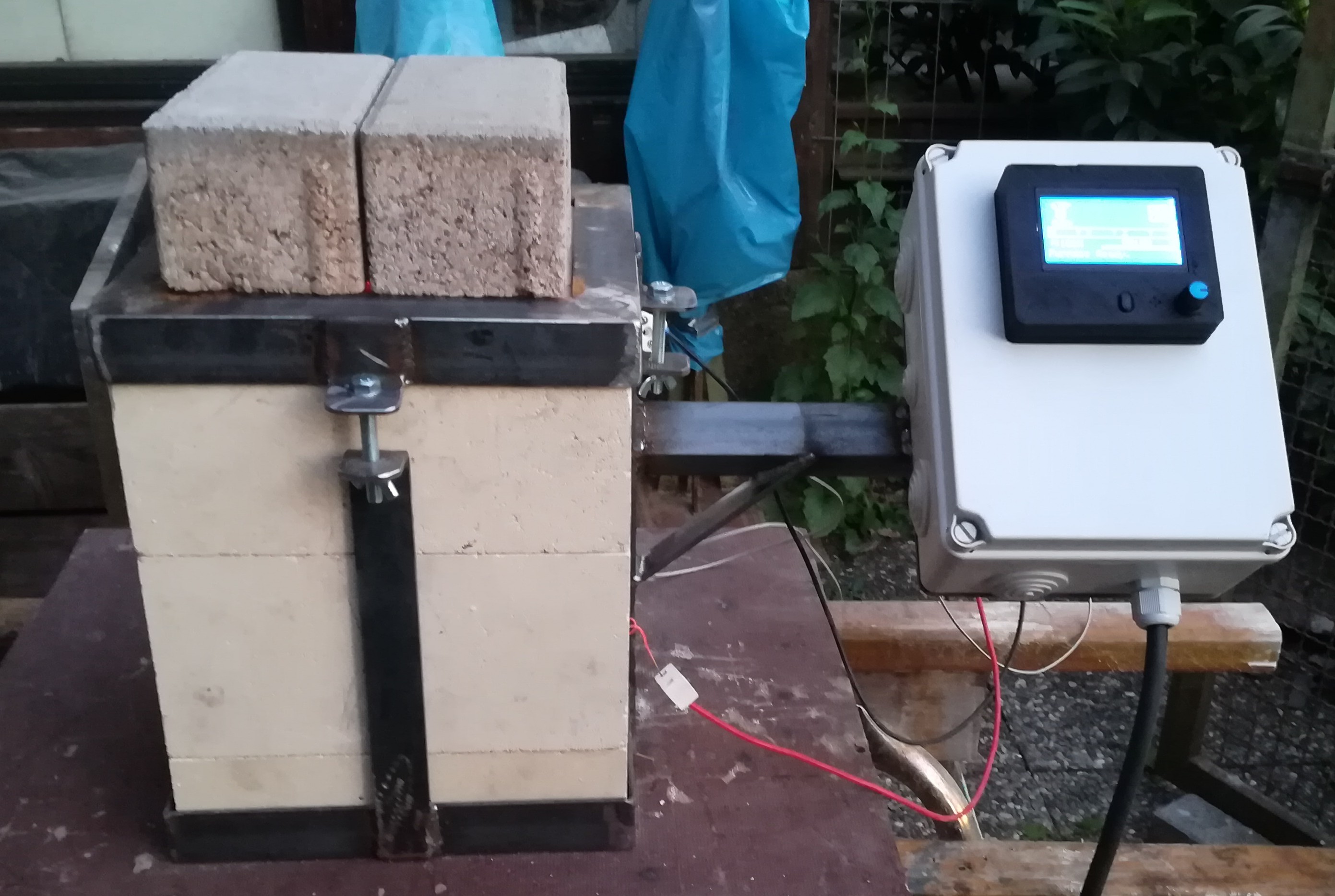

In the last few weeks I built a furnace together with a friend - He did the cutting and welding and I did the electronics.

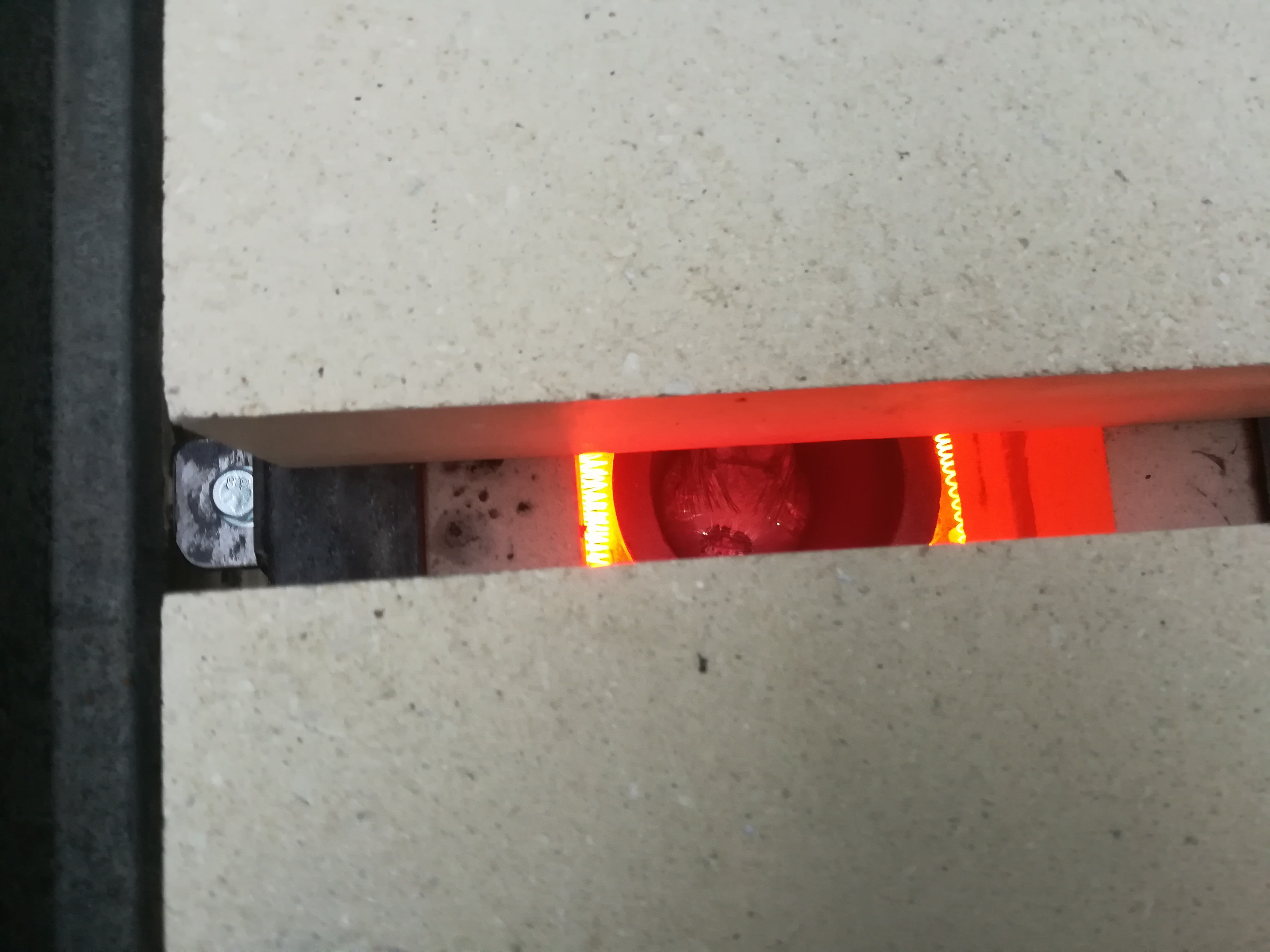

Yesterday we tested cooking something on it and melting aluminium.

Both worked good, but it took some time to get the pan and the crucible to the right temperature.

I think the next thing will be building a clay and sand toolhead.

I read that clay is not a good choice for casting molds and so I will try to optimize the printhead for plaster/gypsum printing.

Update:

I tried casting plaster for another project and now I know that plaster stays liquid only for a very short time - So I think it is not suitable for printing with it and I will try out clay.

Ordered Clay for testing.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.