This respirator project is driven by the following top level requirements (with thoughts/consequences listed below):

- Producible in bulk by the smallest possible team:

- Focus on maker-level CNC machines and vacuum forming to make many parts quickly.

- Avoid 3D printing, which is too slow to be scalable.

- Avoid manual labor wherever possible, especially skilled labor.

- As cheap as possible:

- Doctors and nurses are busy, must be able to throw away masks rather than wash/reuse.

- I'm expecting to fund this out of my own pocket, must be affordable

- No off-the-shelf filter:

- As of the time of writing, effectively all filters (even those inadequate for filtering sub-micron virus particles) are out of stock.

- The mask must be flexible, to be used with whatever ad-hoc filter media is available on hand.

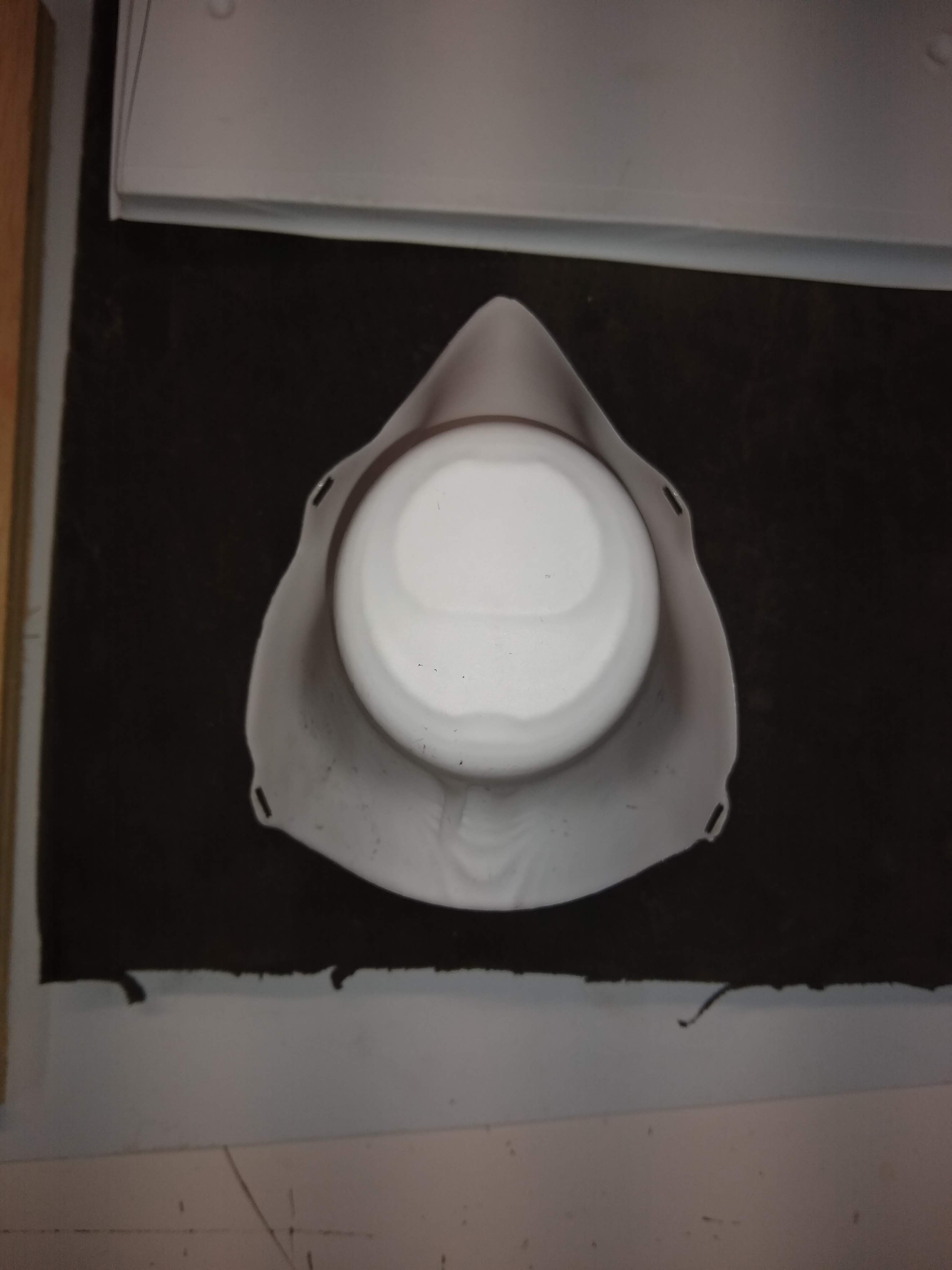

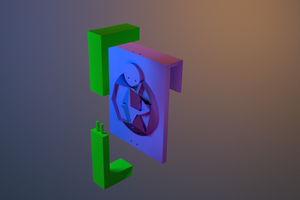

To satisfy these requirements, I'm pursuing a design based around a vacuum formed shell. To form a tight fit against the face, a lasercut foam gasket is glued to the rim of the mask.

The main 'trick' to this design is how it forms the filter: the mask has a conical section with holes on the end, which allows a matching conical shim to wedge inside, trapping a piece of fabric or other filter medium against the end of the mask.

Andy

Andy

Zachary Marlow

Zachary Marlow

Roger

Roger

Alessia Ianni-Palarchio

Alessia Ianni-Palarchio

I'd like to come and pitch in and I can pledge a donation for materials when you need it. Send me a paypal address or other means to donate.