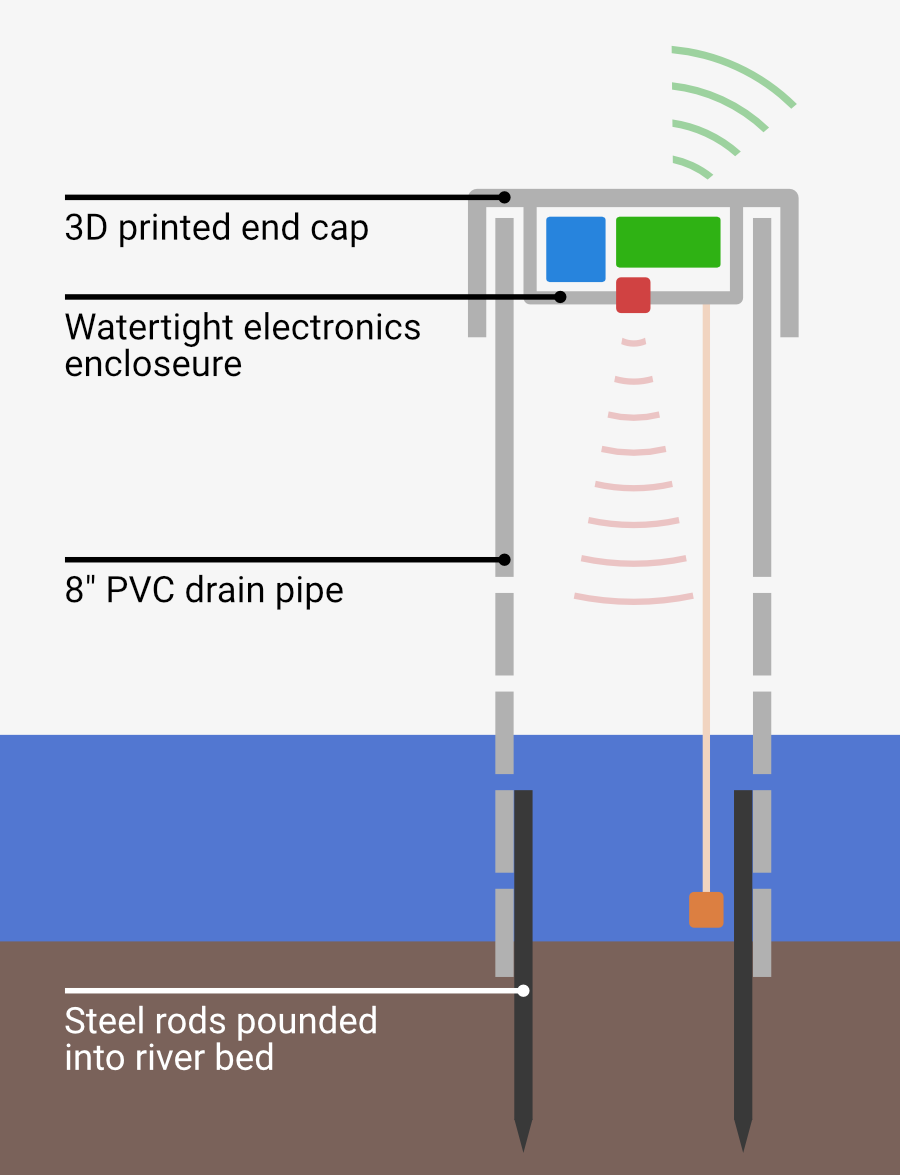

I've been working on an alternative sensor version for areas where natural conditions or people are likely to damage the device. The idea of a fully enclosed PVC sensor design came from my mentor session with Bruce Dominguez. While this design will be harder to install, it will be much more resilient to damage.

Currently I am working on modeling up the new design in fusion and creating a new BOM. I want to make sure all the parts are still easy to find and relatively low cost. My main concerns with the design are the buildup of debris that may occur at the holes in the PVC and the potential for ultrasonic signals to bounce around inside the chamber before making their way back to the sensor, skewing readings. The only real way to test these things is by actually building a prototype of the device.

Rohan Menon

Rohan Menon

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Cool! I am also designing a tide sensor around a very similar concept. Ultrasonic sensor inside a PVC pipe. I can mount it to a piling though, so I'm going to leave the bottom open.

I also want to use the smallest diameter pipe possible. I look forward to hearing about your experiments with accuracy of the ultrasonic sensor. Have you thought of varying pipe diameter? I hypothesize that if I go too small I will start to get unwanted reflections.

Are you sure? yes | no

Yeah that was my concern as well. I was thinking about designing for an 8" sewer pipe, but the size is definitely less than ideal.

I have been thinking about switching to a laser ToF sensor. They are pretty affordable ($15), but they don't reflect well on water. The approach would likely require a float inside the tube to measure against. However, the spread of laser ToF is less than a few degrees meaning that a 3" pipe would probably be more than enough. Then of course, there's a much greater change of jamming but the trade off may be worth it.

Are you sure? yes | no