I've been tweaking the 3D designs to use an angled dispensing approach, rather than the horizontal approach used in FED3. The angled approach is interesting, in that it doesn't require a "foot" to prohibit multiple pellets from dispensing, which is a common solution for this problem used in most commercial pellet dispensers, as well as FED3. Notice the "foot" poking in on the top of pellet hopper of FED3:

While the foot method works, it can crush pellets and create dust, which leads to pellet jams. The angled approach uses gravity to keep multiple pellets from aligning over the dispensing tube, thereby obviating the need for the foot. It creates much less dust and seems to be more resistant to jamming.

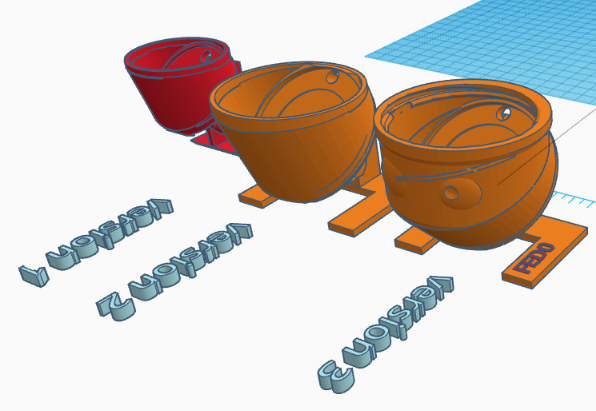

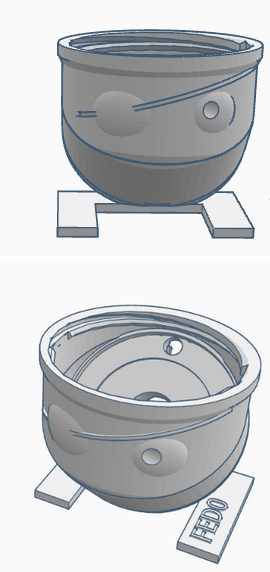

I went through three major revisions of the design, with the first version containing a pellet disk and hopper the same size as FED3. While this worked, the angled disk is less space efficient as it can only be ~1/3 filled with pellets or it risks dispensing multiples. So this design only fit ~150 pellets. I made two adjustments to increase the overall size of the device (version 2), and make it bulge out a bit at the bottom (version 3). Version 3 can fit >500 pellets without dispensing multiples. These are printed in PLA on a Sindoh 3DWox1 printer.

Version 3 also seemed to be begging for some decoration so I also gave him an eyepatch :)

Version 3 also seemed to be begging for some decoration so I also gave him an eyepatch :)

Lex Kravitz

Lex Kravitz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.