It's certainly exciting to be finally having the first batch of prototype boards and FPC manufactured.

PCB Manufacture:

This batch features all the 0.8mm FR4 boards that that used to prototype the following:

Touch-D Module:

- Touch Core

- Click Interface

- Side Interfaces

- Button Board

SMART Scroll Module:

- Scroll Core

- Scroll Interface

- Side Interfaces

Interfaces:

These interface boards were added to the 0.8mm panels

- Thumb Module Interfaces

- Core Module interfaces

The Thumb Module Interface board comes in very handy when developing an module programming and debug station

FPC Manufacture:

I got three FPC Cables made to finish off the Touch-D and SMART Scroll Modules. They were fairly easy to have made they just require three things:

FPC Design Tip:

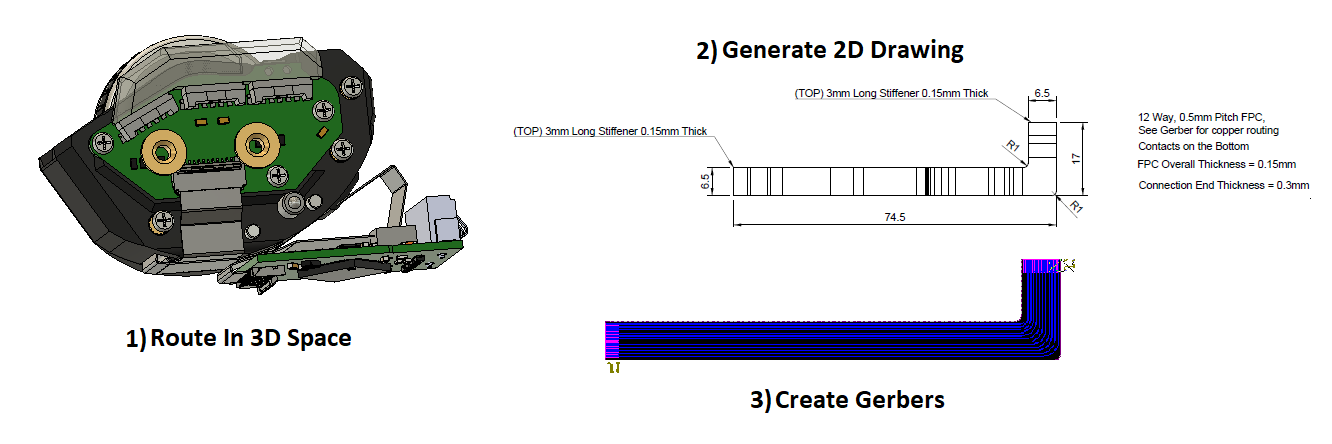

For anyone wanting to design FPC cables I would recommend using the 'sheet metal' tools in Autodesk fusion 360. It works a treat and lets you route the FPC in 3D then will automatically generate the flat view with dimensions.

But why design a custom FPC when you can buy them?

The problem with off the shelf FPC cables is at they aren't as flexible as one would think. I purchased quite a few and found they had a bend radius of about 3mm. Now this does sound good big but lets add some preservative:

The above image is the Internals of the Touch-D module each PCB seen is 0.8mm FR4 and all fixings are very small M1.6. Once you start having 3mm bend rads on all FPC cables you would find that there is no space of the module the 'sweep'.

benw

benw

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.