THOUGHTS ON M10CUBE AFTER ONE YEAR

After about a year from introducing M10CUBE idea a lot have been happening.

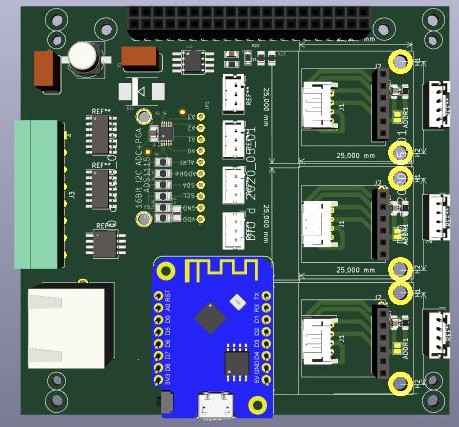

First we have hands on first version of PCB for M10INPUT, M10OUTPUT, M10SENSOR, M10PROTOTYPE, M10PSU

Unfortunately because of the heavy work done on the M10SENSOR module, work on testing the other modules left behind.

Fortunately these months with testing left us experience for the overall design too. New hardware ideas found on the table as well.

So looking forward in overhauling the M10CUBE some things to consider are some thoughts.

M10CUBE initial idea

The initial goal for M10CUBE idea with what is in mind after 1 year remains almost the same:

To design development ecosystem, capable to accommodate known platforms like Arduino and Raspberry.

Not as separate products but as a unit and be able to interact each other. As far as we know there is no similar product in the market. M10CUBE must not only to able to be used as a testing, developing or production ready hardware but all its parts can be reusable for other projects (or come from other projects).

M10CUBE can become for the microelectronics DIY community as the tool known as “swish army knife “

Not as good as it is each tool separately, but does the job. And does it well.

Many Hat or no Hat hardware exists to plug on the Raspberry Platform and many excellent ad-dons (shields or whatever word various Arduino incarnations use) exist for the Arduino Platform .

Many excellent PLC products exists for both Platforms. Many excellent company development hardware is out there. Without them new ideas will be impossible to implement.

Still it is almost impossible to get these boards and make a production system.

First of all because of the different PCB dimensions. That is natural.

Arduino’ s miracle made well known companies to embed Arduino UNO bus on their dev boards.

That is very well done but now IOT explosion, the plethora of the proposed system and buses brought us in a situation without any standard on how all these devices to interconnect, easy and in an economical way.

Is it a standard like this exist and I am aware of it? May me.

Not even the I2C bus has a standard pin out. Grove connector system is on the correct direction but it is not enough.

Some companies made attempts to fix the position of frequently used pins like SPI, I2C, UART but no one went beyond that to unite the two platforms in a full stack-able system so to be used from developing to production.

Not to be misunderstood. There is no way to substitute a company's developing boards here.

Run your tests and experiment with these boards. Then design and build some PCBs with M10CUBE specs plug them together and voila!

The professional stack-able developing or production system is lying on your bench.

Make it a PLC , a Home Automation controller, an Environmental sensor or anything you like. Use the boards again and again in other projects.

The good thing is that you already know the enclosure dimensions and with a little copy paste your 3D printed enclosure is there! Share it with the community. That is a better idea on how all these can be connected together.

We are not saying M10CUBE idea is best but we are trying to figure out how that can be done.

None seems to care . Maybe because that is impossible?

All these excellent products (Arduino PLC and Raspberry PLC products, M5stack, the list is endless) have one thing in common. Their ego. Mostly the care about “themselves” and not what other companies doing. Not a bad thing because to build an excellent product you need to be specific in the design board. Then is the market. You design something to make money. That drives the hole Industry. And that is a good thing. But not always good for the end user.

The money lost the last 40 years because the companies fighting to push their own standards to consumer products. Money out of our pockets . Lost for ever.

Just to remind the mobile charger connector. So many incarnations until everybody confirmed on usb. So bad for our pockets and most for the environment. How difficult was that?

M10CUBE tries to overcome that attempting to make a concept, a platform, a "glue", a development platform, a production ready hardware or all the above. M10CUBE is a dream to help the community to use ARDUINO and RASPBERRY platforms like a LOGO.

The power of M10CUBE is not the individual PCBs but the modularity offered by the concept.

We continue to say M10CUBE is kind of “hardware agnostic” means that new hardware ideas can lay on it as long as M10CUBE is solid. That is the electric and mechanical specifications are well designed and accepted.

In a sense M10CUBE is not magic at all. It is common sense. Proposes a well designed environment to embrace all problems arisen from a world totally without any standards on that field. Not an easy thing or if I may say, very very hard to achieve.

That is why needs M10CUBE needs a lot of inspiration a lot of discussion, a lot of courage and a little bit of luck.

But there is hope.

M10CUBE hardware specs are still for discussion before we are going back to drowning board.

1 - A hardware platform that will accommodate The Raspberry PI 4.

Plans for future. Compute module or other modules is easy to design.

2 - A 40 long pin connector for interconnecting the various stacked PCBs. The connector has the same footprint as the Raspberry Pi.

Plans for future. A high speed duplex differential bus can be used instead. Same idea used in modern PLCs today. All other hardware on board can remain the same. That is easy for PCB designers to make something completely different as the inter-board communication as concern.

3 - A proposition for PCB dimensions 90x90mm

- A proposition for outer dimensions of the box 100x100mm. A possible construction of 100x100x100 mm cube can be constructed accommodating various modules.

4 - Directions and template hardware will help others to design various boards using STM32, Analog, CAN BUS, Encoders etc. Only imagination stops someone to design something useful and benefit from others work on M10CUBE.

5 - Project always will be OSHW certified. So you can copy and make money if you like. In fact we like to see you doing it.

6 – The need for a plug-in system for the various hardware used on board.

That was done in an idea last year but it is abandoned. We may today find a better solution.

See on photo last year's abandoned idea

So many years in industry one thing we learn for sure. The only way for a product to be a success story (and probably designers make money) must be open source and best to be OSHW certified.

One thing we learn from our testing on m10sensor was, that plug in modules saved our time . So on redesigning we will consider all components to have a snap in capability.

For instance when testing m10sensor boards with LoRa subsystem lot of m10sensor PCBs destroyed (soldering and unsoldering the modules) . The same for GPS.

So there is an urgent need for all subsystems to be plug in and play. A small breakout PCB is needed. That is to be able not only to remove the broken sub-module, but also to unplug it and reuse it in another project. That must be applied for all sensors used, LoRa and GPS subsystem.

Which bring us to one million dollar question. What is the correct footprint (pin-out) for the breakout PCB that will accommodate all the above?

OK still looking. We are sure we will find it.

Why? Because it is common scene to exist and then we will find it.

Is M10CUBE for dreamers? Yes it is. M10CUBE as we dream it is not static but dynamic. Nobody knows how it can be in an other incarnation after some years.

Do not forget Apple, Arduino, Raspberry came to light because dreamers are real. Well better to say visioneers.

In the end only dreamers will drive us to Mars

So we are keep dreaming and keep working hard to find solutions that will make M10CUBE a product useful to the community.

Only imagination will stop someone to design useful things on the M10CUBE ecosystem and others to benefit from his work.

VASILIS VORRIAS

VASILIS VORRIAS

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.