The navigation sensor stack-up is designed to be extremely durable while also being capable of detecting delicate pressure and delivering precision direction control.

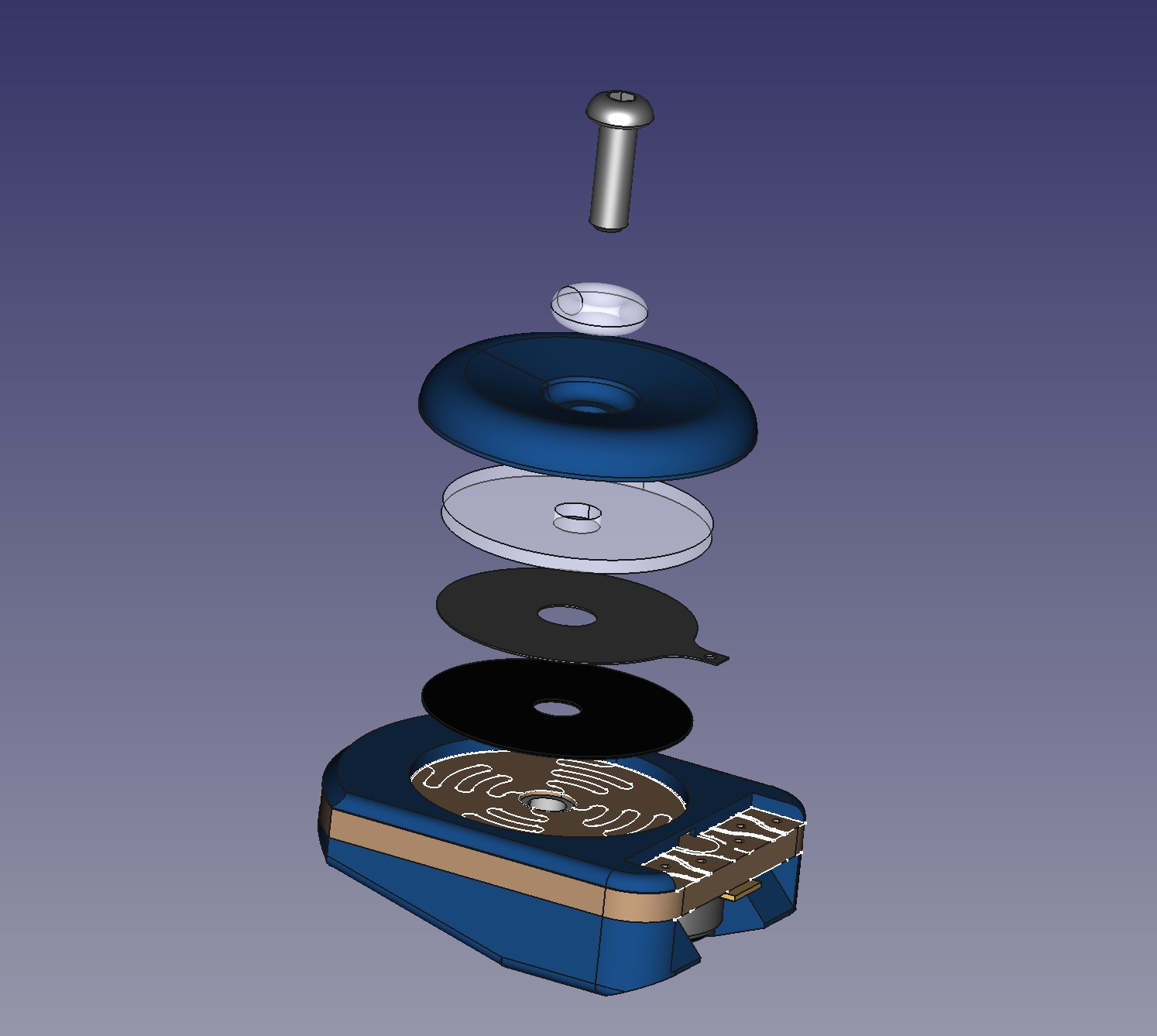

Here is an exploded view of the navigation sensor:

From the top down we have:

From the top down we have:

- M2 screw - Maintains alignment and provides preload force

- Silicone O-Ring - Distributes preload force to the Nav-Button

- Nav-Button - The raised rim transmits the user's applied pressure downward

- Silicone Disc - Spreads out pressure to improve directional sensitivity

- Common Contact - Thin copper contact shared by the four sensor zones

- Force Sensitive Polymer Disc - Carbon-impregnated polyolefin (3M 1706)

- PCB - Interdigitated pattern with four symmetric sensor zones

The result is an array of thru-mode force sensitive resistors. Pressing on the Nav-Button compresses the conductive polymer decreasing the resistance between the common contact and the zone(s) below the area where the pressure is applied.

This approach has some important advantages over the more commonly used shunt-mode construction.

Thru mode force sensitive resistors respond faster and behave more linearly during the force

loading phase. They can also be force

preloaded, which reduces the minimum force required

for contact detection and improves the output linearity.

oneohm

oneohm

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.