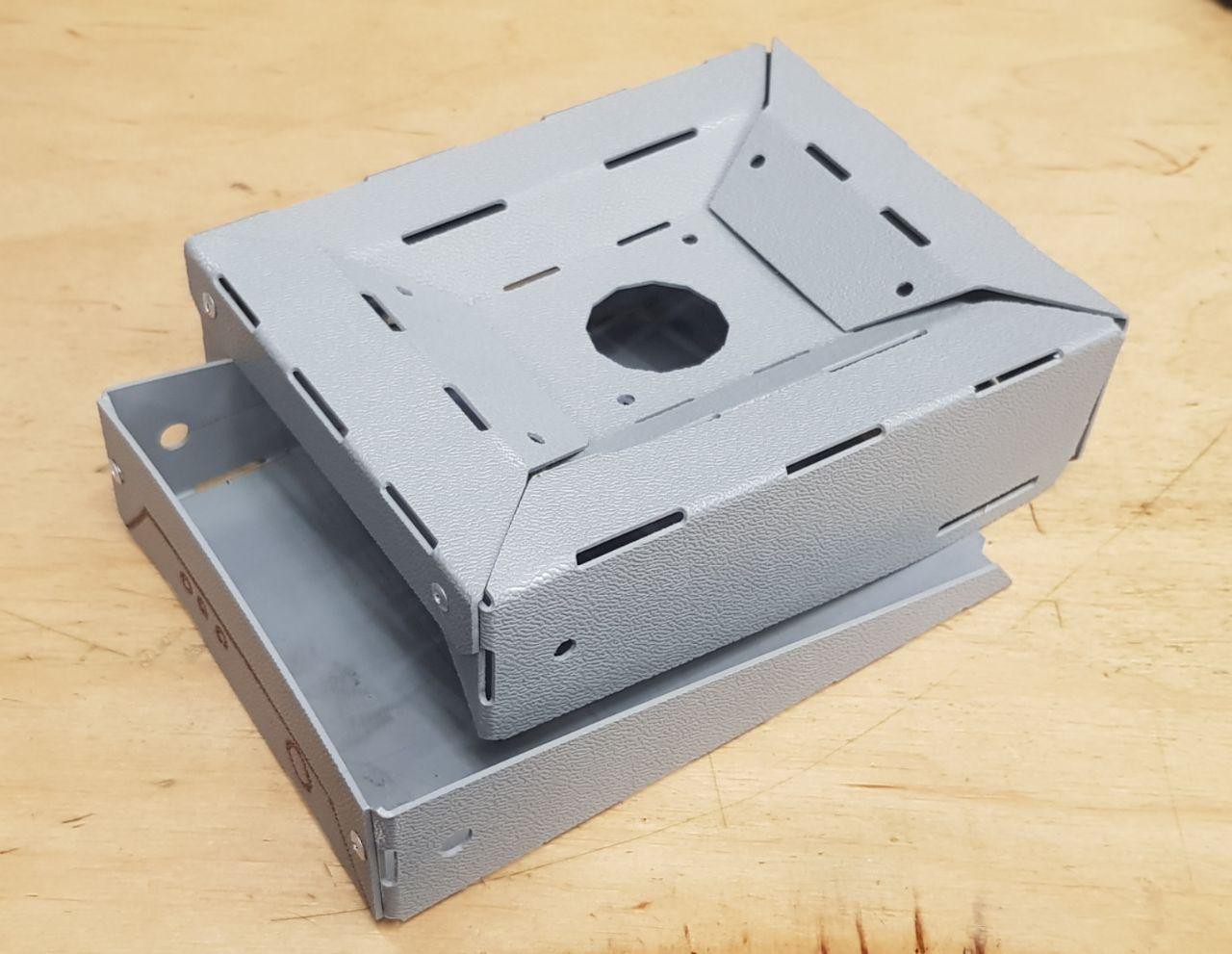

The initial design was made of 5mm and 3mm plastic which is difficult to bend and process, requiring tight tolerances and lots of manual labor.

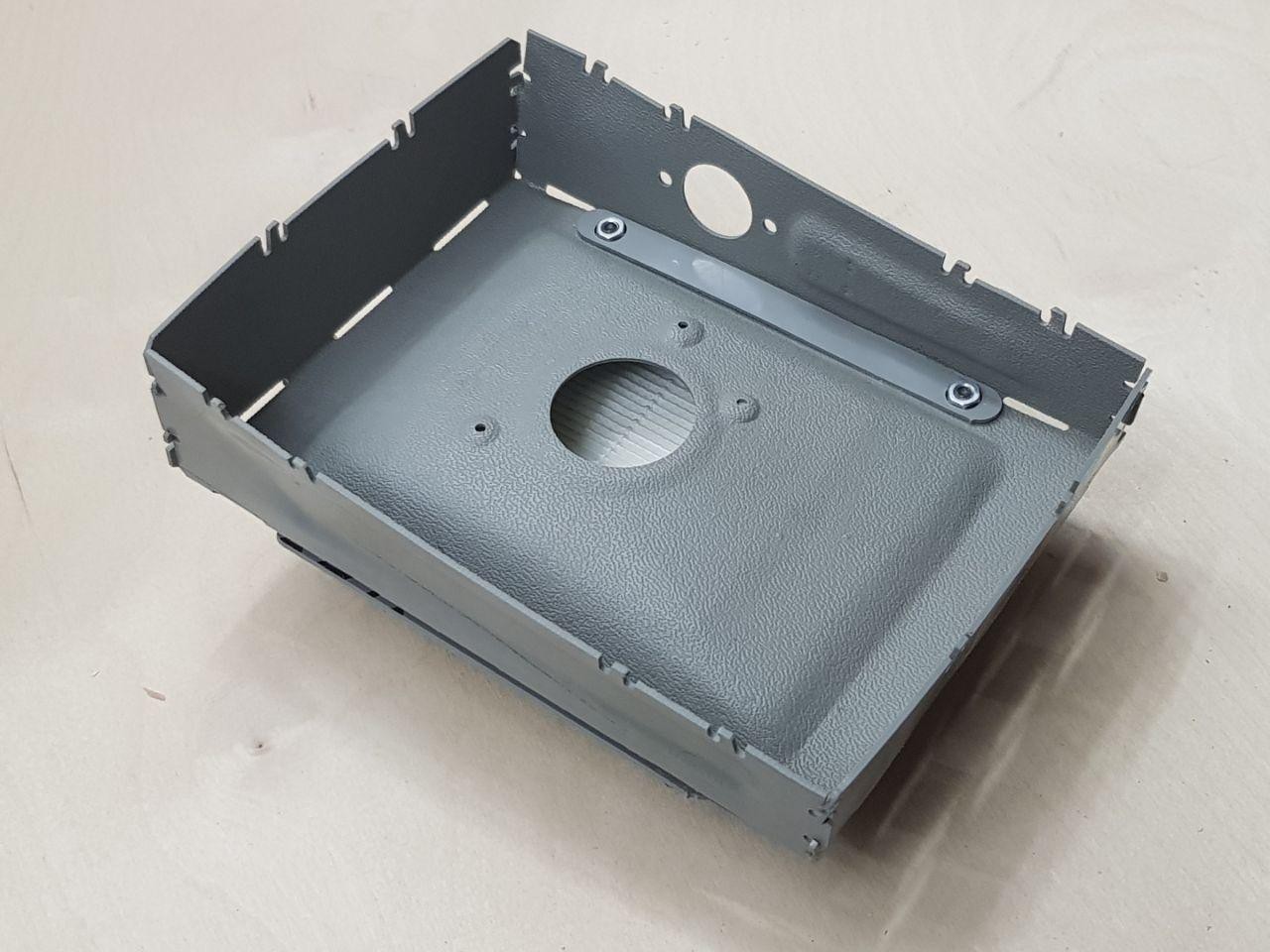

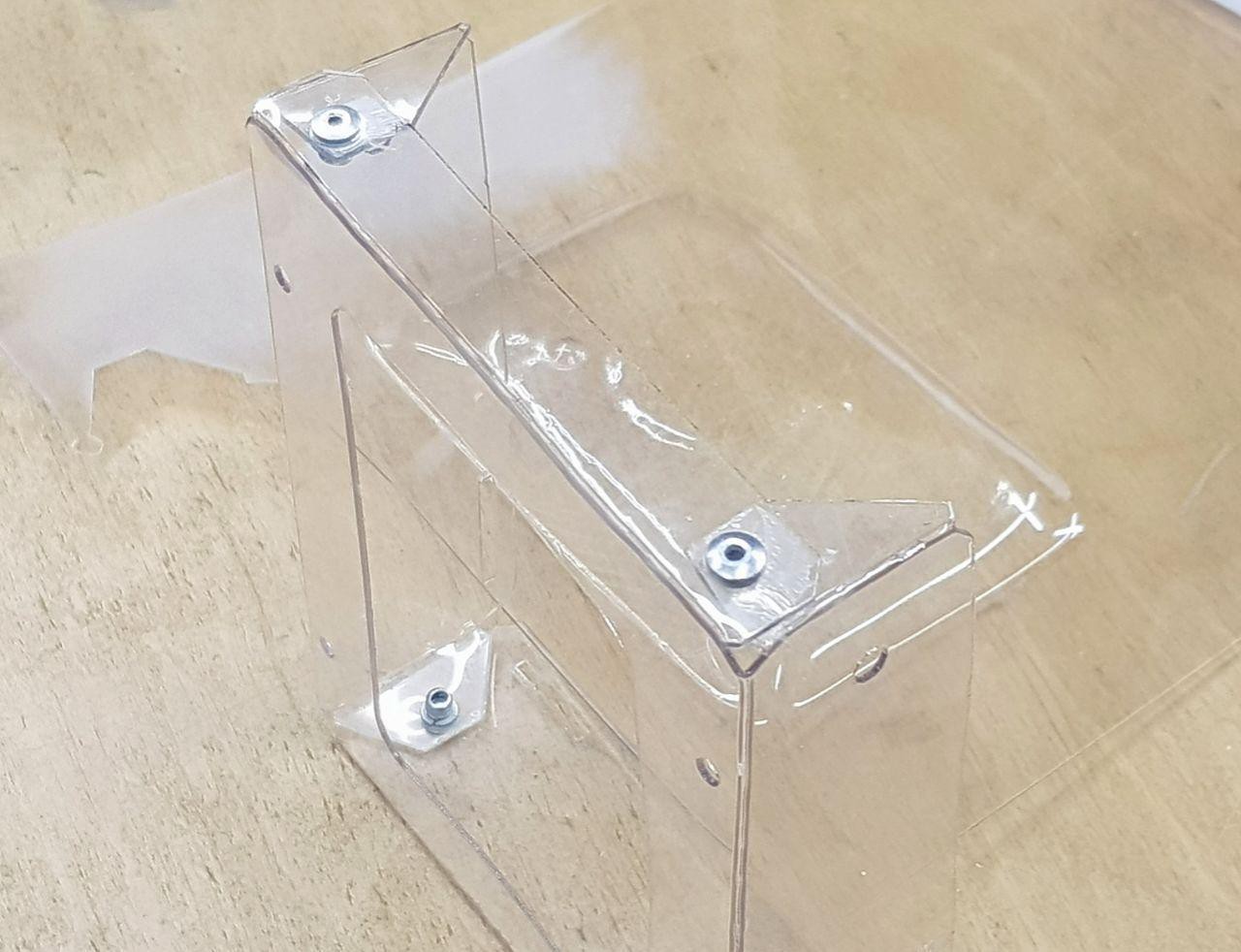

Last week we've been trying to optimize the design for thin plastic and make it lasercut-only, with rivets for edges. Here's a mockup of an origami-ish layout with a recess for the air flow.

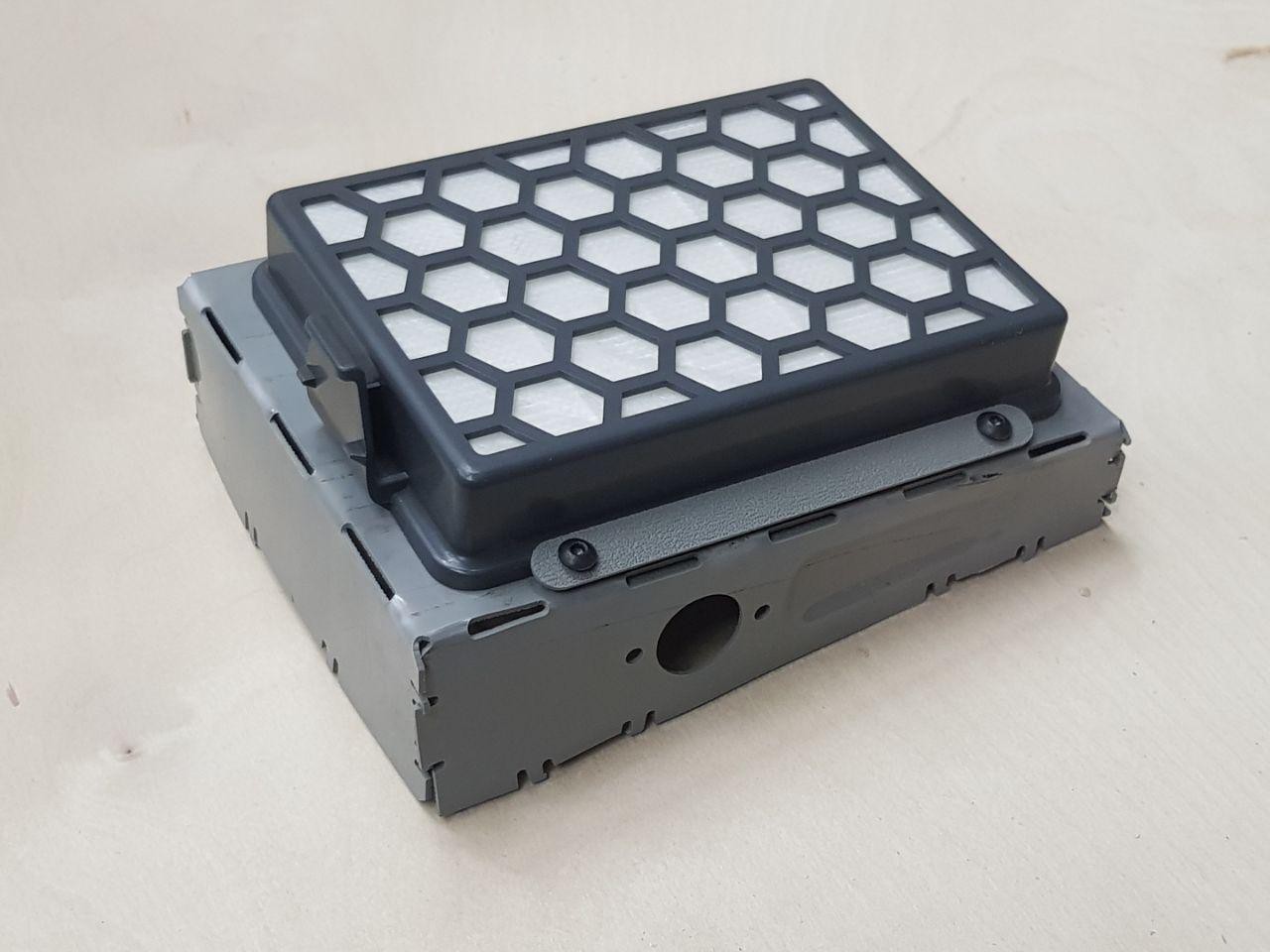

Using HEPA filter's built-in gasket, we've separated the electronics in non-airtight box.

We've also tried snap-joints on edges, which didn't work reliably for thin stock.

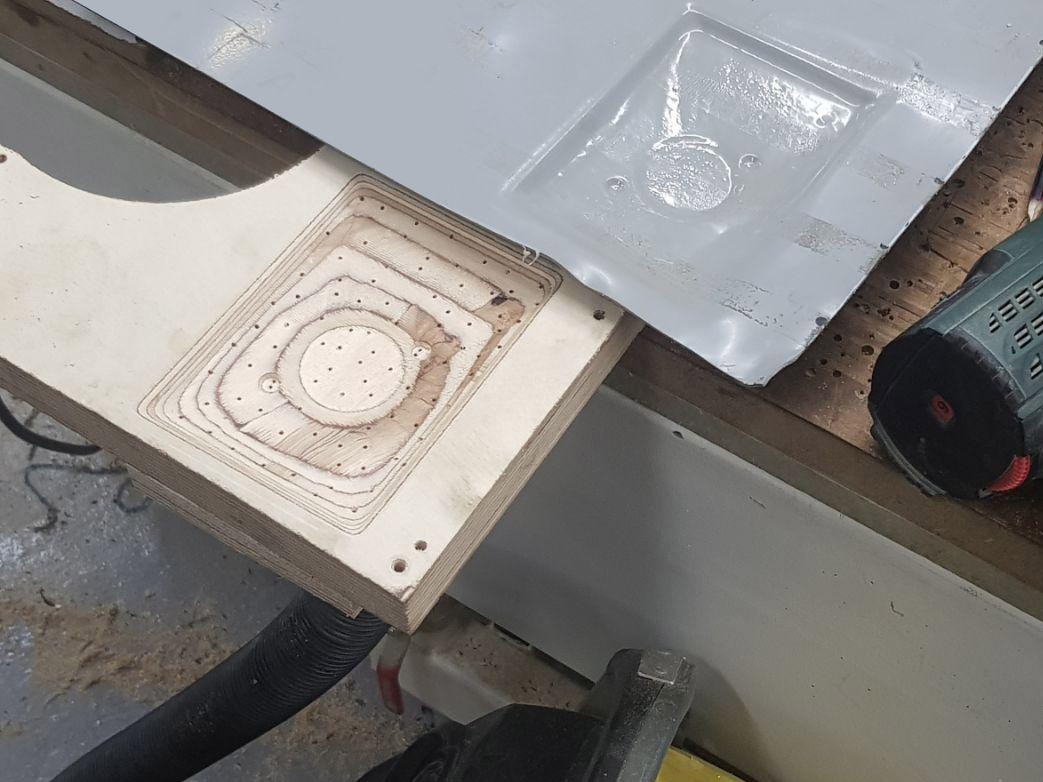

With a shop vac and a heat gun we molded the interior, providing the rigid frame for the filter and the space for air flow

We've also tried different plastics and settled on 1mm PETg - it's way easier to vacuum form, bends by hand without breaking and cuts nicely on a laser.

Dmytro

Dmytro

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.