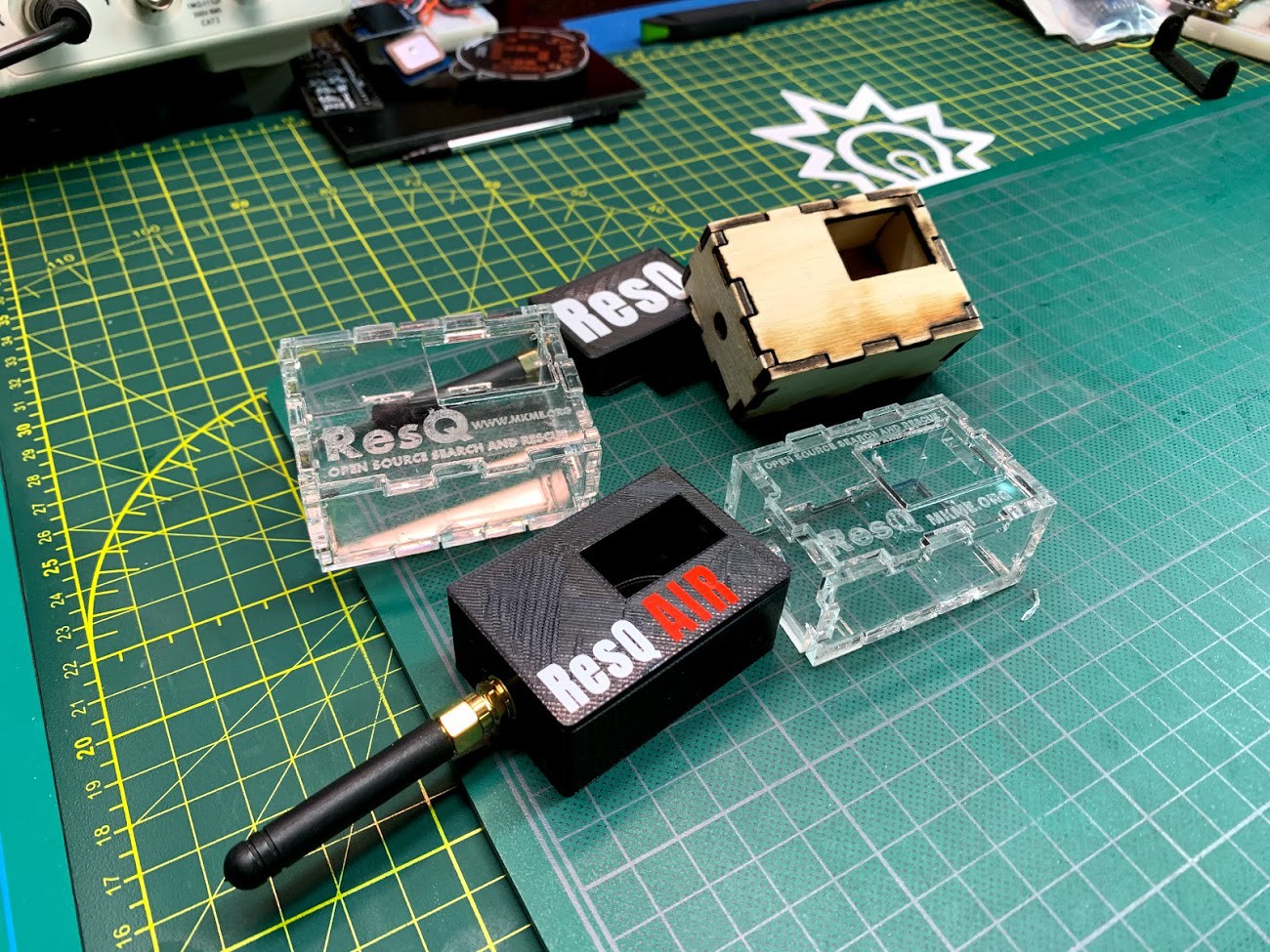

The weather started out horrible this weekend (kept my test subjects away from the beach) so I decided to tackle the case problem. I really like the state of my 3D printed cases:

But there are 2 fairly serious issues:

- Not everyone has access to a 3D printer

- 3D printed cases would cost a lot for me to ship in kits

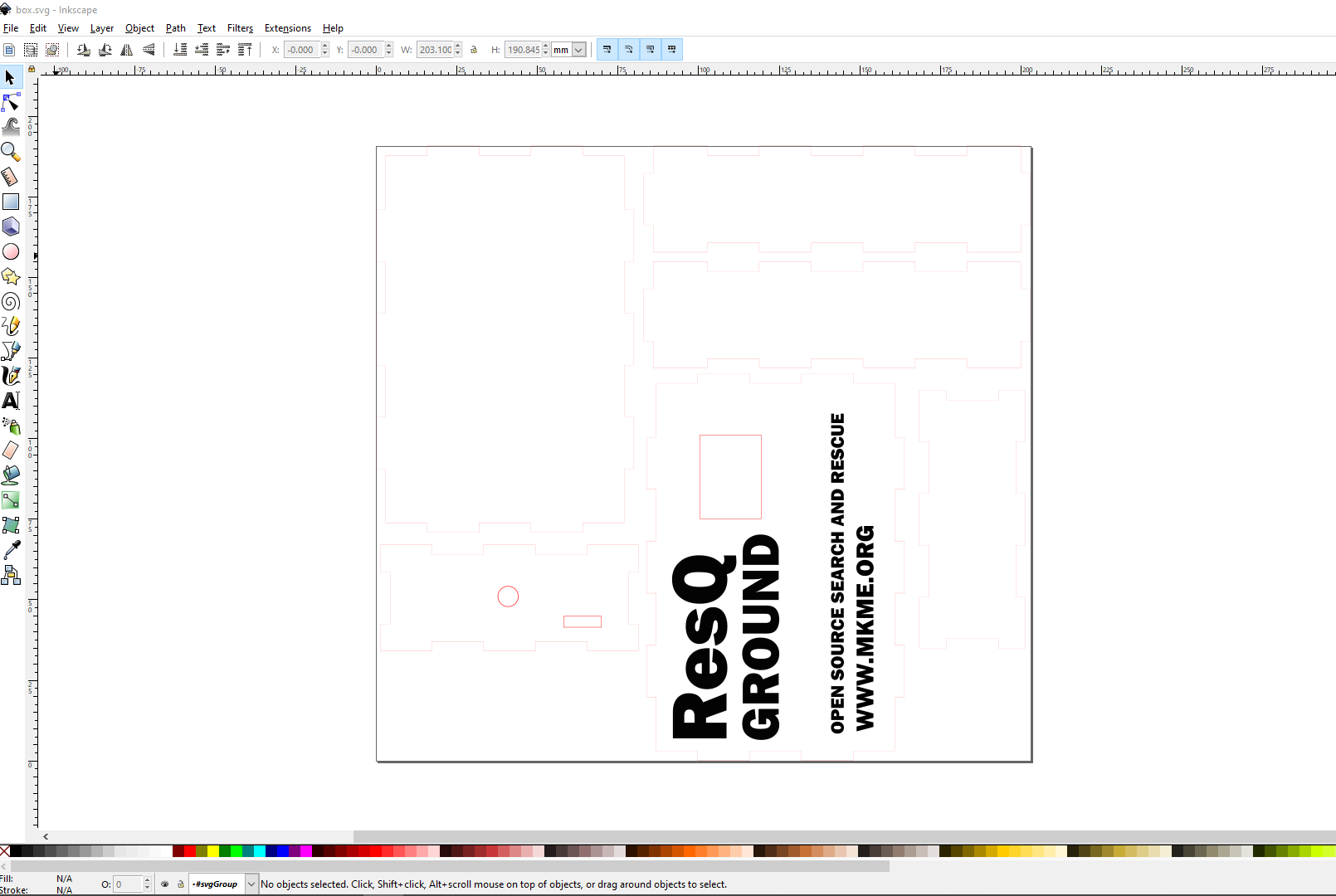

Since I really would like to do some kits to possibly bootstrap some funds for the project I really need to solve these. I decided to make a 2D design that can be laser-cut, CNC machined or even cut by hand.

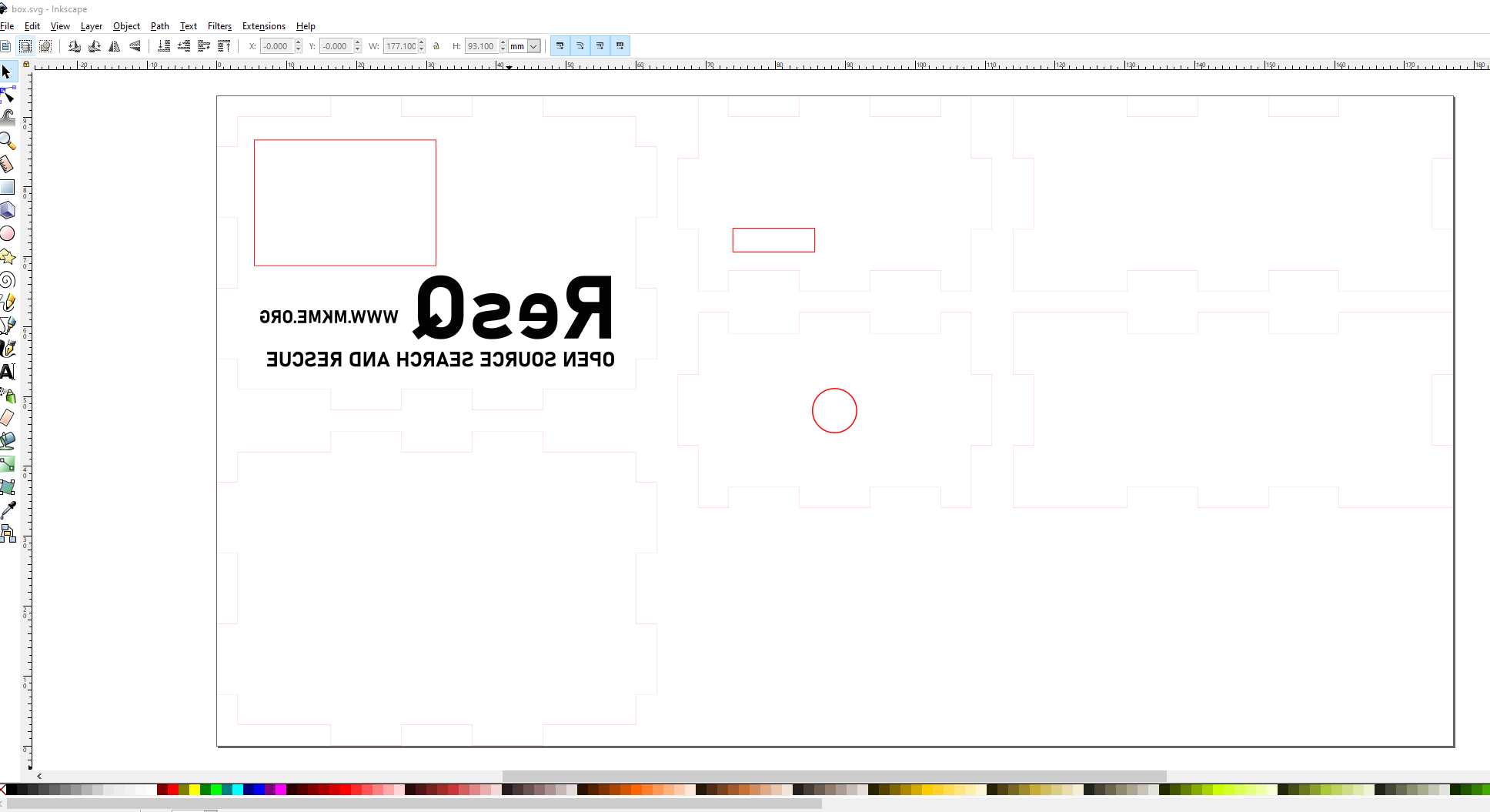

I made this design and modified it in Inkscape to cut on my laser cutter:

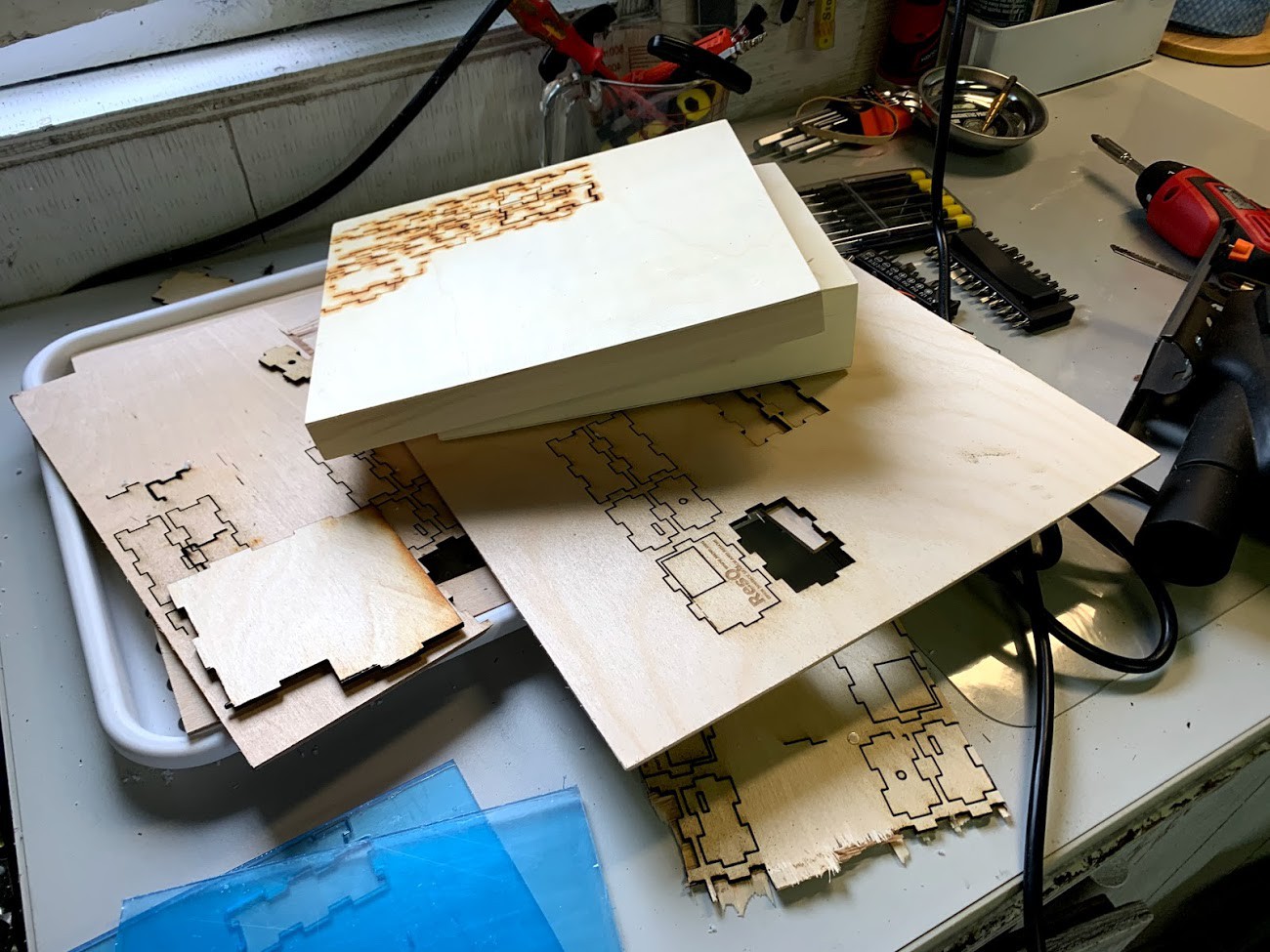

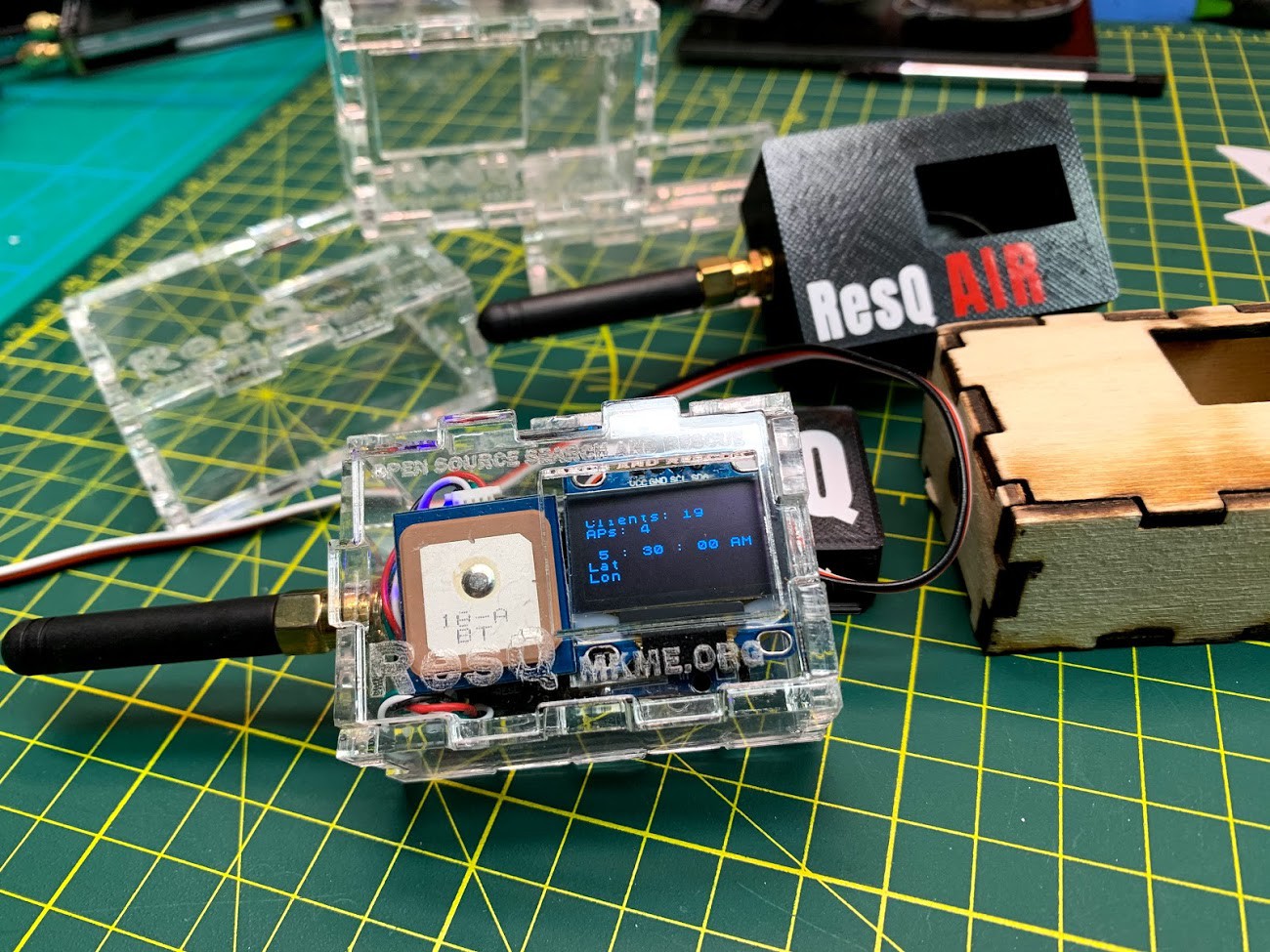

It came out pretty great but I had some issues. As usual, I spent the entire weekend iterating the design with dimensional and format tweaks. Cutting them and trying the assembly over and over again.

Getting there:

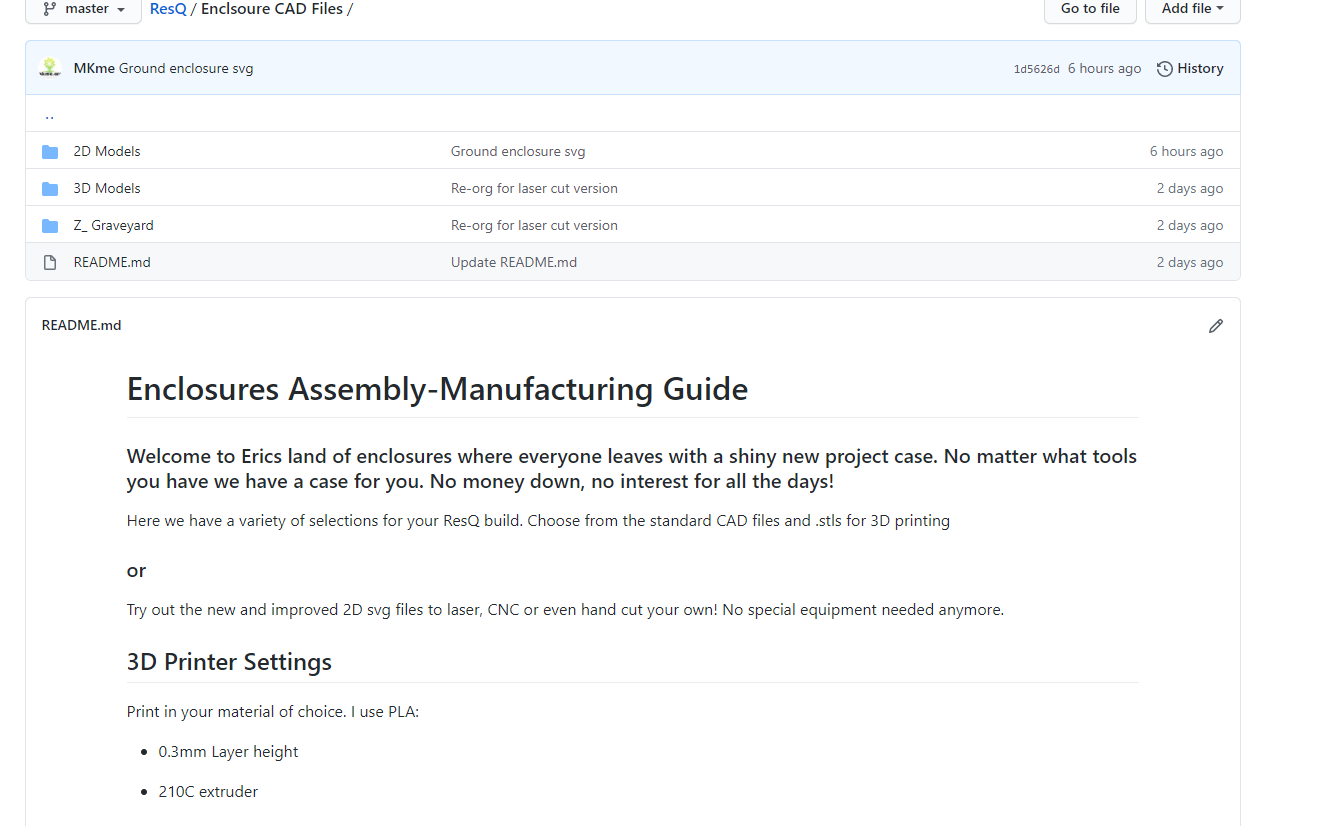

In the end- I now have SVG and DXF files in my GitHub Repo covering an easy to make case for the air unit. I have also added a readme with assembly instructions just for the cases/enclosures and the various methods of making them HERE

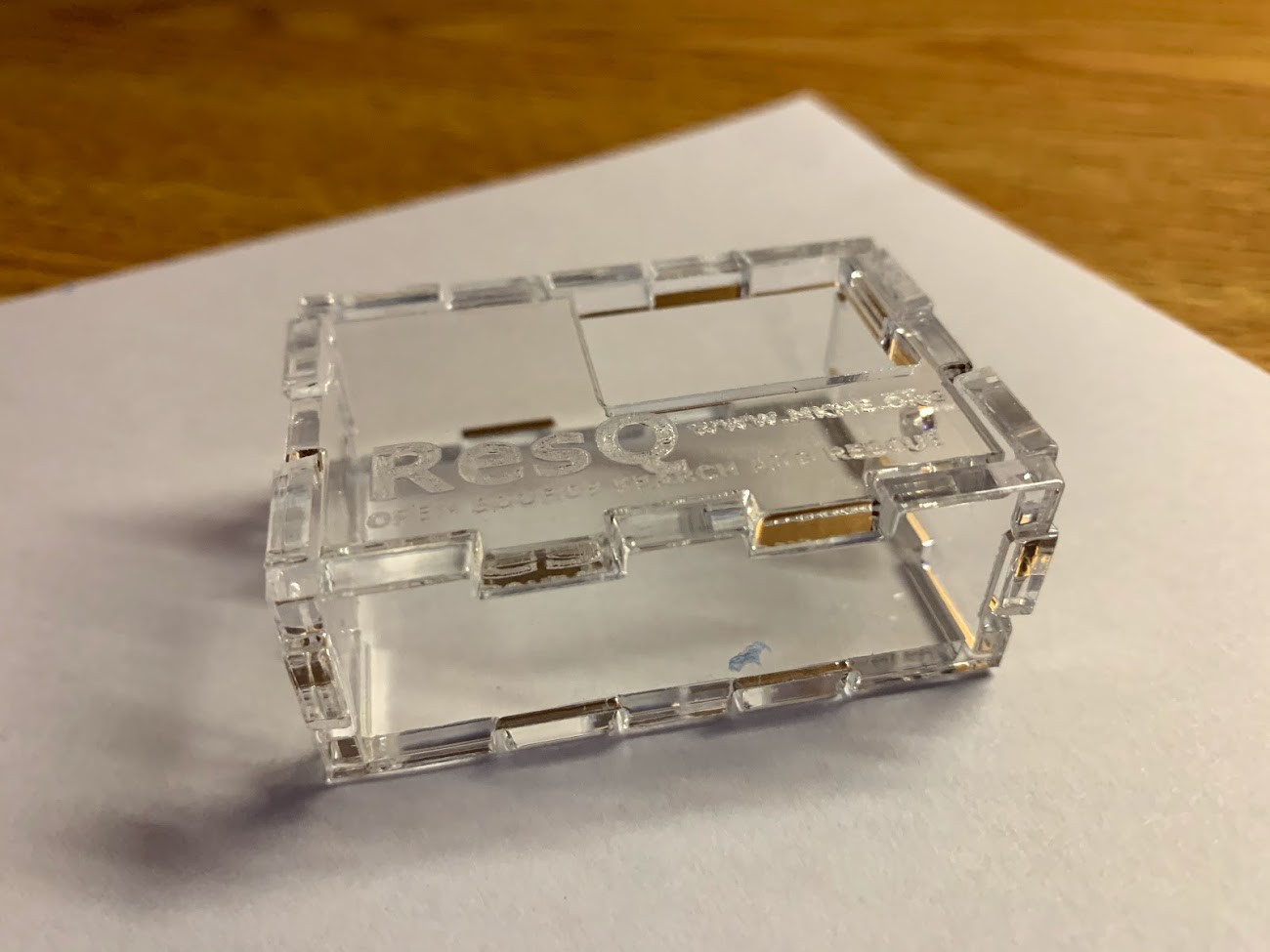

Pretty happy with how it came out!

Being flat 3mm thick material- I can now ship a case with component kits when/if the time comes I actually find some people who actually want to buy a kit 🙂 Both 3mm birch plywood and 3mm acrylic seem to work nicely but the acrylic looks waaaay nicer.

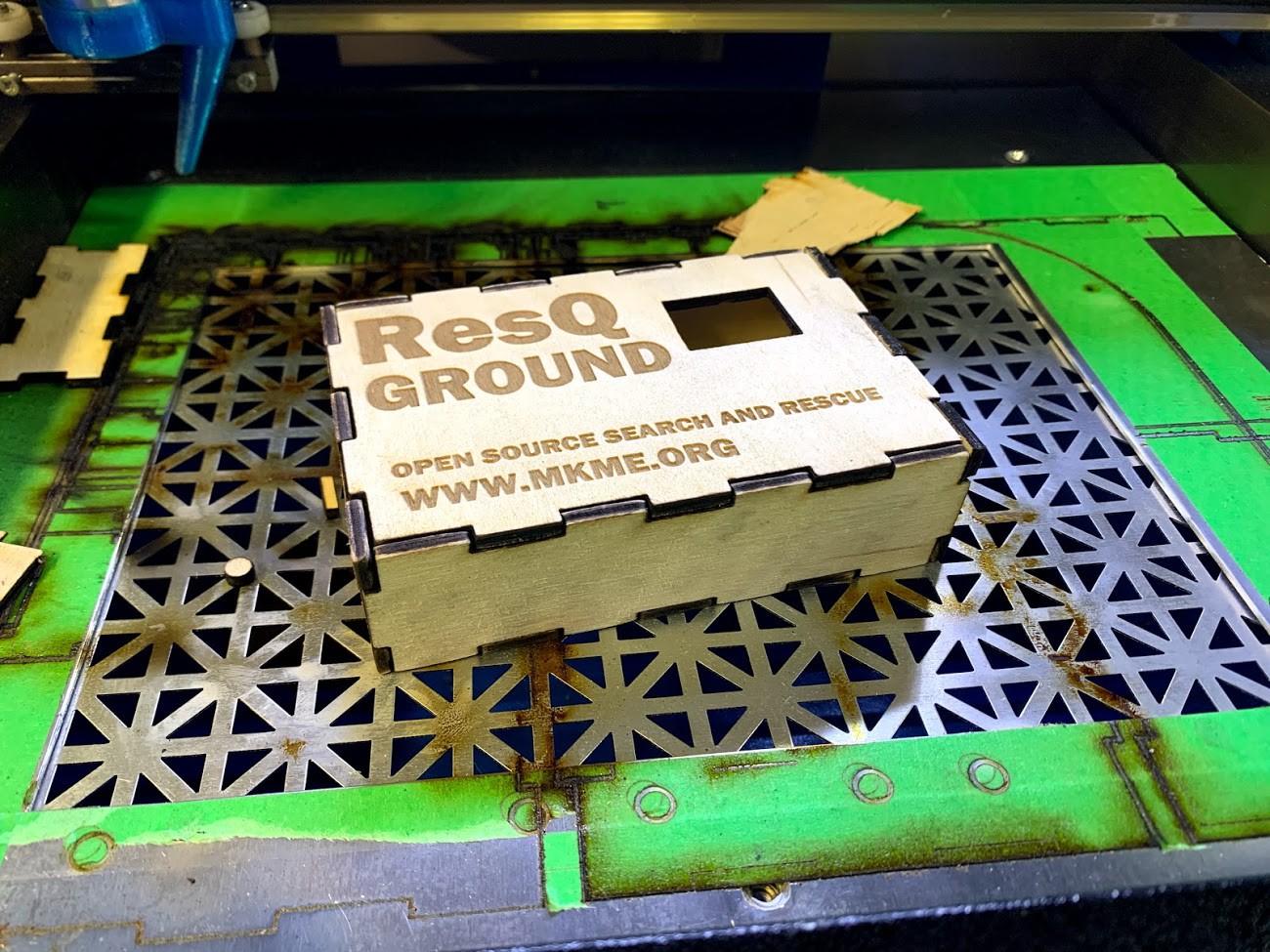

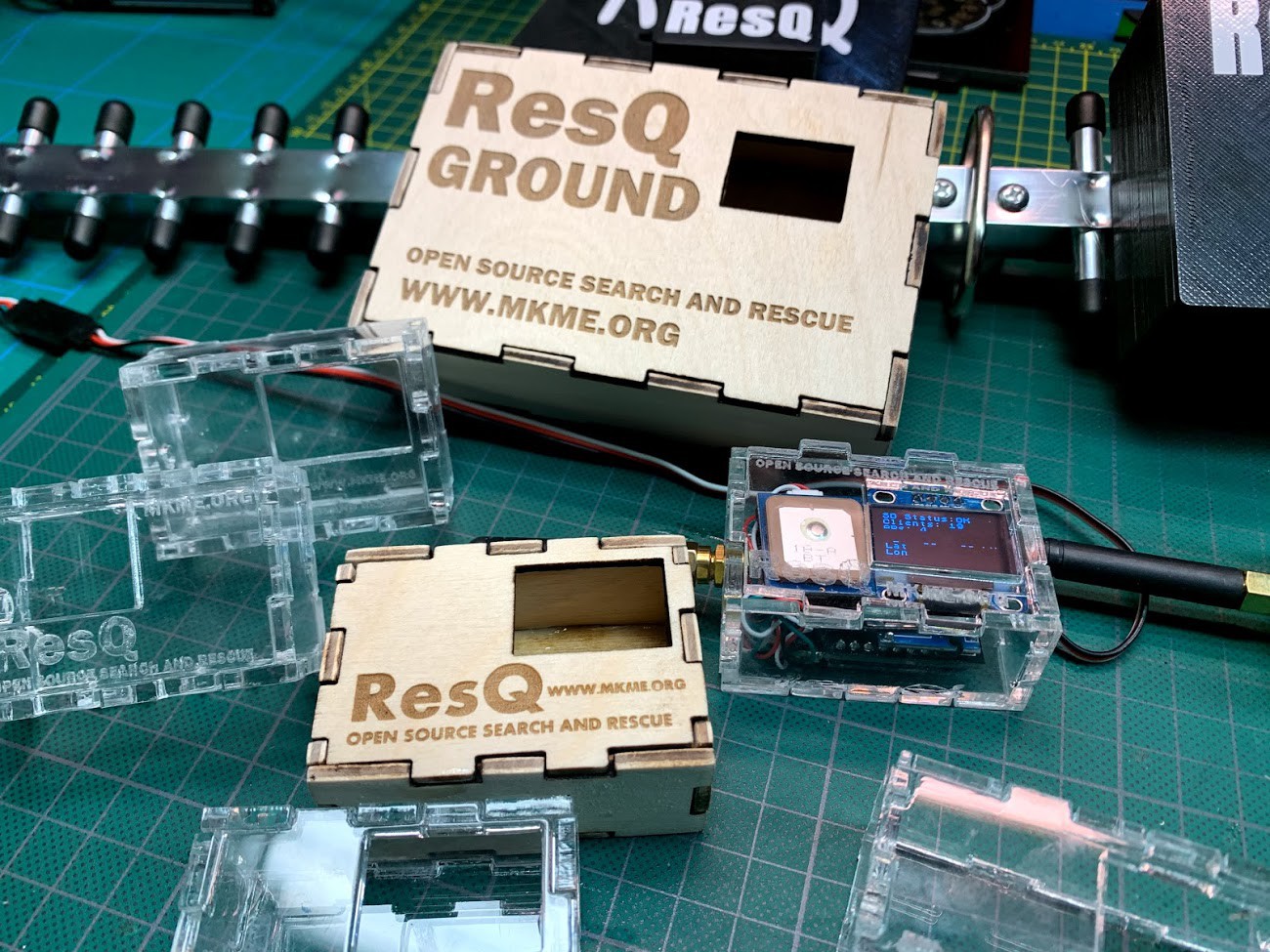

I even went ahead and tackled the ground unit enclosure too. The SVG file was pretty easy since my hardware is the same between air and ground:

It cut out great on the K40:

Then one big happy family was together at last :)

Key takeaway: However long you think it will take to make a simple enclosure- double it... then double it again ;)

Pretty happy with these as the open the door to anyone to make this now without a 3D printer (or with one too)

I ween!

Eric Wiiliam

Eric Wiiliam

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.