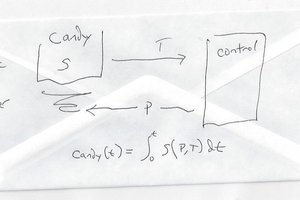

We would like to make indoor farming a sustainable and simple solution for the future. This will be achieved through a fully configurable and automated end-to-end hydroponic farm controller. Hydroponics is an already proven solution for more bountiful crop yields and environmentally safe growing conditions. It’s the future of farming, however it’s a highly technical process and can be extremely tedious to manually monitor. We hope to design a solution that can make hydroponic farming as easy as plug and play. By removing the learning, we can make this a technology that will bring about a new era of crop growing.

Hydroponics is a method to grow plants by exposing roots directly to nutrient solutions. It is a much more efficient agricultural system than traditional farming as it requires 80% less water and at least 20% less space. Growing plants in a hydroponics system is simple to set up but can be difficult to maintain because water pH and nutrient levels require constant manual monitoring. We will automate this process and make hydroponics accessible and integratable into farms and homes.

We will experiment with growing lettuce and mint. This will make hydroponic farms more accessible for the general public as it will be lower cost and easy to use.

We will prototype with the PSoC® 6 WiFi-BT Pioneer Kit (CY8CKIT-062-WIFI-BT)

We will use AWS cloud services for data logging and remote user connectivity. Users can view solution status and other parameters easily from their computer. They can also view these parameters over time in easy to read graphs. Users can also configure their controllers remotely if anomalies are detected. Also, we can offload most of our computing needs to cloud resources for our more complicated needs such as predicting nutrient injections and balancing resources.

We have experience programming bare-metal with NRF52840 for electric skateboard remote and data logging telemetry. Use of bluetooth to connect to mobile app. We have previously worked on a wifi project using ESP32 to scan wifi networks and send data to remote database. As a result we have extensive experience with embedded systems in both bare-metal and RTOS applications in STM32, AVR, PSoC, NRF52.

Kai Yin

Kai Yin

Bill Smith

Bill Smith

YJ

YJ

Darian Johnson

Darian Johnson

John Costik

John Costik

Why only one floor, or is that just to start. There is (or at least was) a commercial indoor farm in Chicago area where they had a lot of their plants growing in multilayered / tiered hanging planters. Personally, long time ago, I dreamed up plans for a large concrete structure of several acres, that would have several floors with the main water reservoir at the top. Small pool at the bottom to use a single pump to return the water to the top instead of having water at the floor level and have several pumps to pump it everywhere. That way you just have valves and gravity to control the flow of water/solution to the plants. That water could also turn micro hydrogenies to provide small electric power (not meant to be over unity). But the floors would be laid out in such a way that rails could be used to allow overhead arms to tend to the plants. A small scale of this is somewhere on this site. A system of mirrored tubes and servo controlled mirrors would be used to bring in sunlight where and when needed.