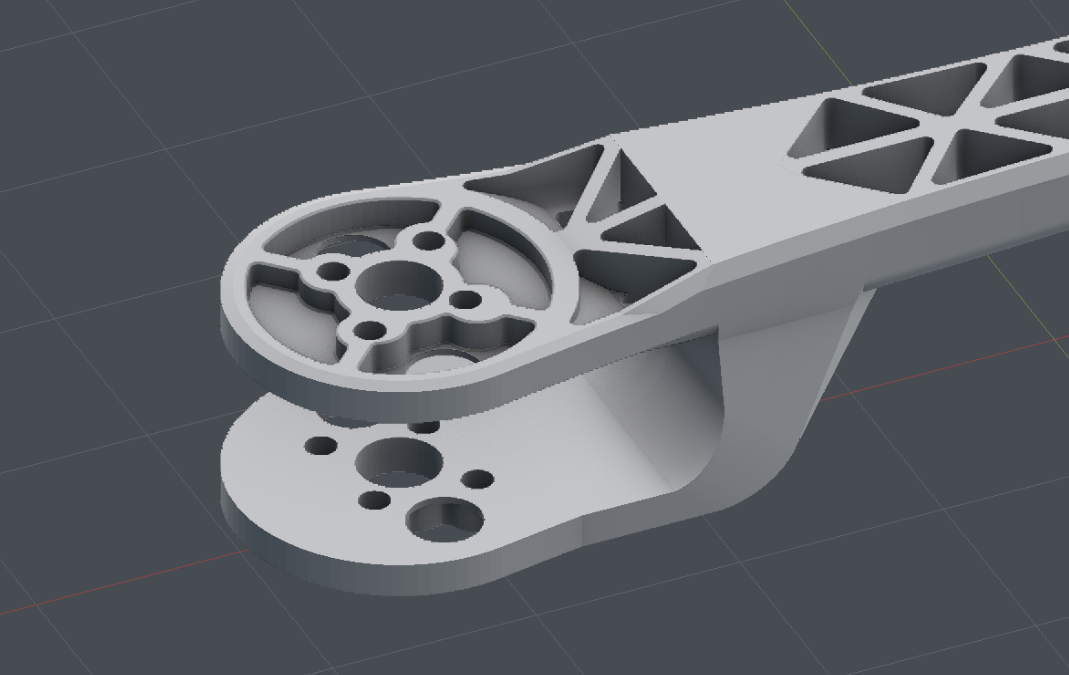

This is a modified DJI style f450/f550 arm, which has been cloned dozens of times and is more popular now than ever because DJI retired the style. One of the aspects of running dual motors on one arm is the weight issue. Double motors , motor controllers and wiring can increase weight. Some buy frames like a hex 6 from Tarot for example that is made from a bunch of carbon fiber tubes. There are a few reasons I am not doing this. First, The carbon frames can be 200-600 dollars by themselves. If you buy china direct it is cheaper, but then there is the risk of getting fake carbon fiber that is mostly fiberglass or even plastic that has been hydrodipped to look like carbon. 3D printing is a good alternative to carbon in the sense you can make them lighter with infill, and still get a functional end product. It may not be carbon fiber, but functional is what we are looking for right now. Initially I will use PLA, but for motor temperature reasons I may swap to PETG to handle higher heat and still maintain a light weight part.

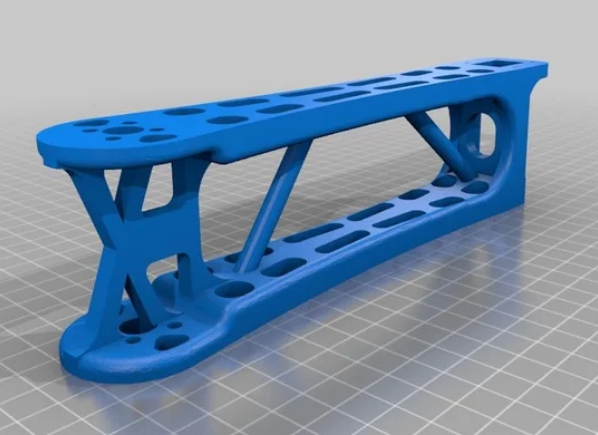

Below is a iteration of the F450/F550 Drone arm that is basically two full arms slapped together with 8 supports connecting them. I am sure this is very stiff, but it also more than doubles the material and weight of the arms. Multiply that few ounces by 6 and you added an extra pound to your aircraft for no good reason.

In addition, I am not fond of the look either. It looks like it would fly like a brick.

So I appreciate this guys efforts in his design , but we need to go a little lighter...

Josh Starnes

Josh Starnes

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.