The operating procedure has had the single most influence on the design of the Gen 2 prototype. The reason for this is simple - the most unpredictable and difficult to control component of the OpenFluidWamer solution is the human operator. Understanding how relays, 7 segment displays, button switches, temperature switches etc. can fail and cause a hazardous condition is a trivial task compared to understanding all the ways the human operator can make an incorrect action that results in harm to the themselves or the patient. Therefore, it has been a major focus of the OpenFluidWarmer design to reduce the number of opportunities that the device can be used incorrectly by the operator and cause a hazardous condition.

See "OpenFluidWamer_OperatingProcedure" in the files section of this project for the latest version of the OpenFluidWamer operating procedure.

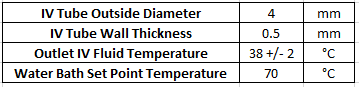

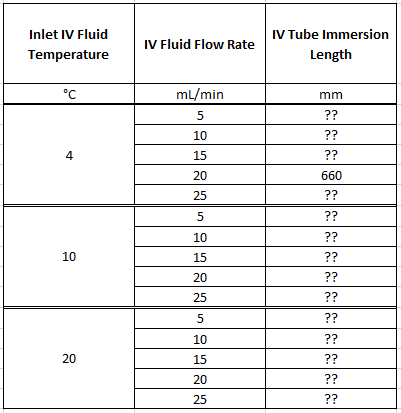

The first step of the operating procedure is to determine which operational parameters to use during device operation. The current approach is to have the operator use lookup tables in the user manual (or perhaps on a laminated sheet attached to the device) to determine the appropriate operational parameters. The images that follow are the proposed format for these lookup tables.

You may notice that there is currently only one entry in the IV Tube Immersion Length column. This one entry represents the only test conditions that the Gen 2 prototype has been tested to so far. It also represents one of the most challenging thermal performance test cases. Consequently, almost all other test conditions in the table will require that a shorter length of IV tubing be immersed to achieve the 38°C outlet temperature at the 70°C water bath temperature. All the "??" entries represent tests that will be performed in the coming weeks to complete the table.

It is also important to note that the current approach uses a constant water bath temperature of 70°C. If the operator needs to change the IV fluid flow rate, the two ways to implement this change with the device is to either change the water set point temperature or change the length of immersed IV tubing. It is less convenient for the operator to change the water bath set point because of how long it will take the sous vide cooker to bring the water bath to the new set point. Instead, changing the length of immersed IV tubing can be done much quicker and will result in an immediate correction to how much heat is being transferred to the IV fluid.

John Opsahl

John Opsahl

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.