This initial OpenFluidWarmer mechanical design is a result of the last month of research. Each product analysis exercise (cost, souring, heat transfer, competitive analysis, design requirements, etc.) helped to identify design opportunities that I would not have found otherwise. Perhaps equally important, they helped to eliminate the many sub-optimal solutions that were floating around in my head. Because of all the upfront research, I had about 80% clarity on what the mechanical design would look like prior to staring the 3D modelling and working through the dimensional details.

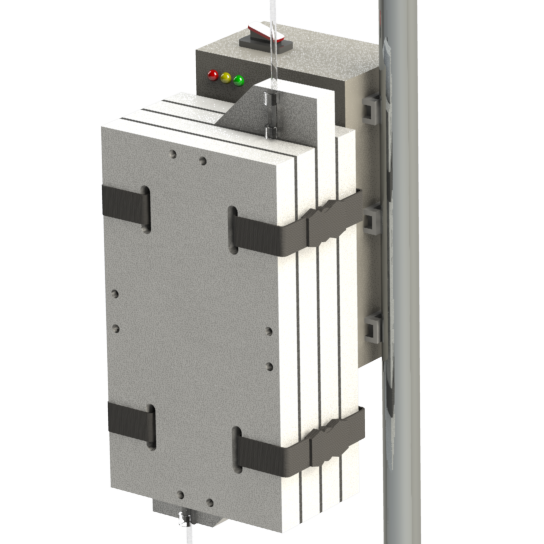

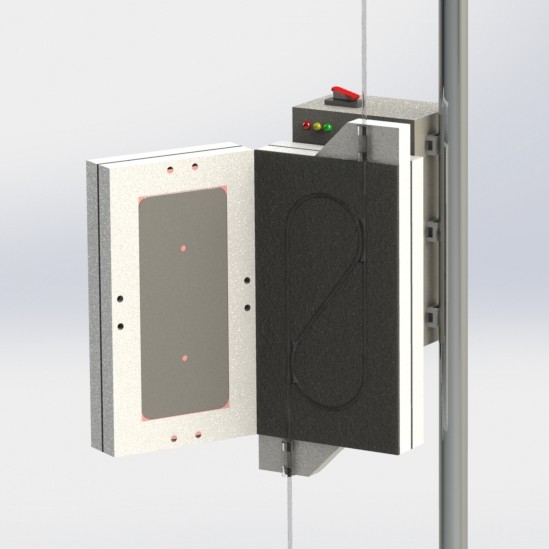

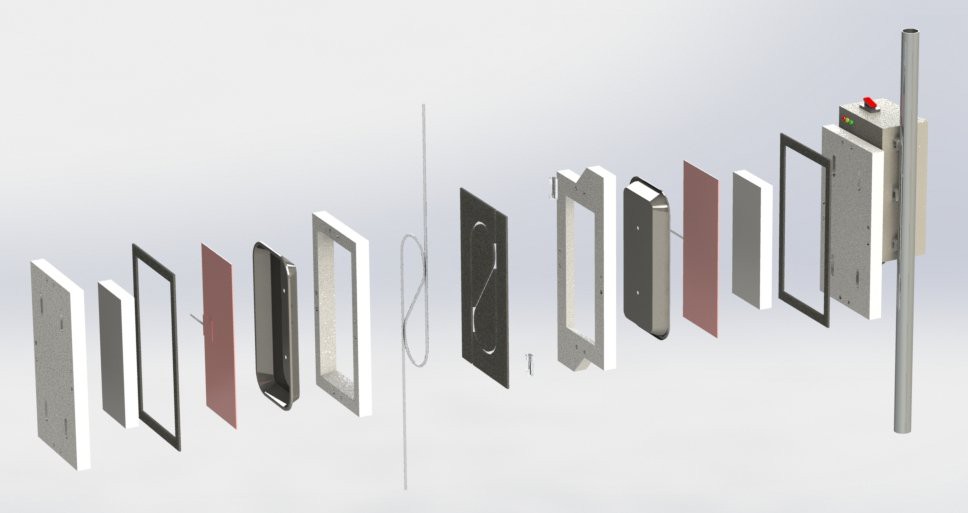

You might have noticed that this new mechanical design has almost no resemblance to the metal tube enclosure prototype that I proposed previously. The main reason I moved away from the metal tube design is because of the poor heat transfer rate from the heaters to the IV fluid. More specifically, the new design requires less length of IV tubing through the device in order to transfer the same amount of heat to the IV fluid. This higher heat transfer coefficient between the heat source and the IV fluid is achieved by sandwiching the IV tubing between two heaters rather than exposing only one side of the IV tubing to the heat transfer surface.

Couple of other interesting details of this design:

- the IV tubing follows a large turning radius path through the device to prevent kinks in the tubing

- the heat transfer contact surface is stainless steel so will not corrode and is able to be cleaned easily

- insulation (i.e. white blocks/frames in the renderings) surrounds the heaters and heat transfer contact surface so that the path of least thermal resistance is from the heat source to the IV fluid

- it should be able to accept all diameters of IV tubing up to 7mm; tubing diameter effects the rate of heat transfer that can be achieved so will result in different maximum allowable fluid flow rates

- the tools required to construct this device are a drill with drill bits, a utility knife, wire cutters, and a soldering iron

- all components are available through the AliExpress website, total cost of all components is just under $90 (still have opportunities to reduce cost to the $80 target)

Most of the components have either already arrived or I can pick them up from the hardware store. The next effort is to build up a prototype and determine the maximum achievable fluid flow rate with this design.

John Opsahl

John Opsahl

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.