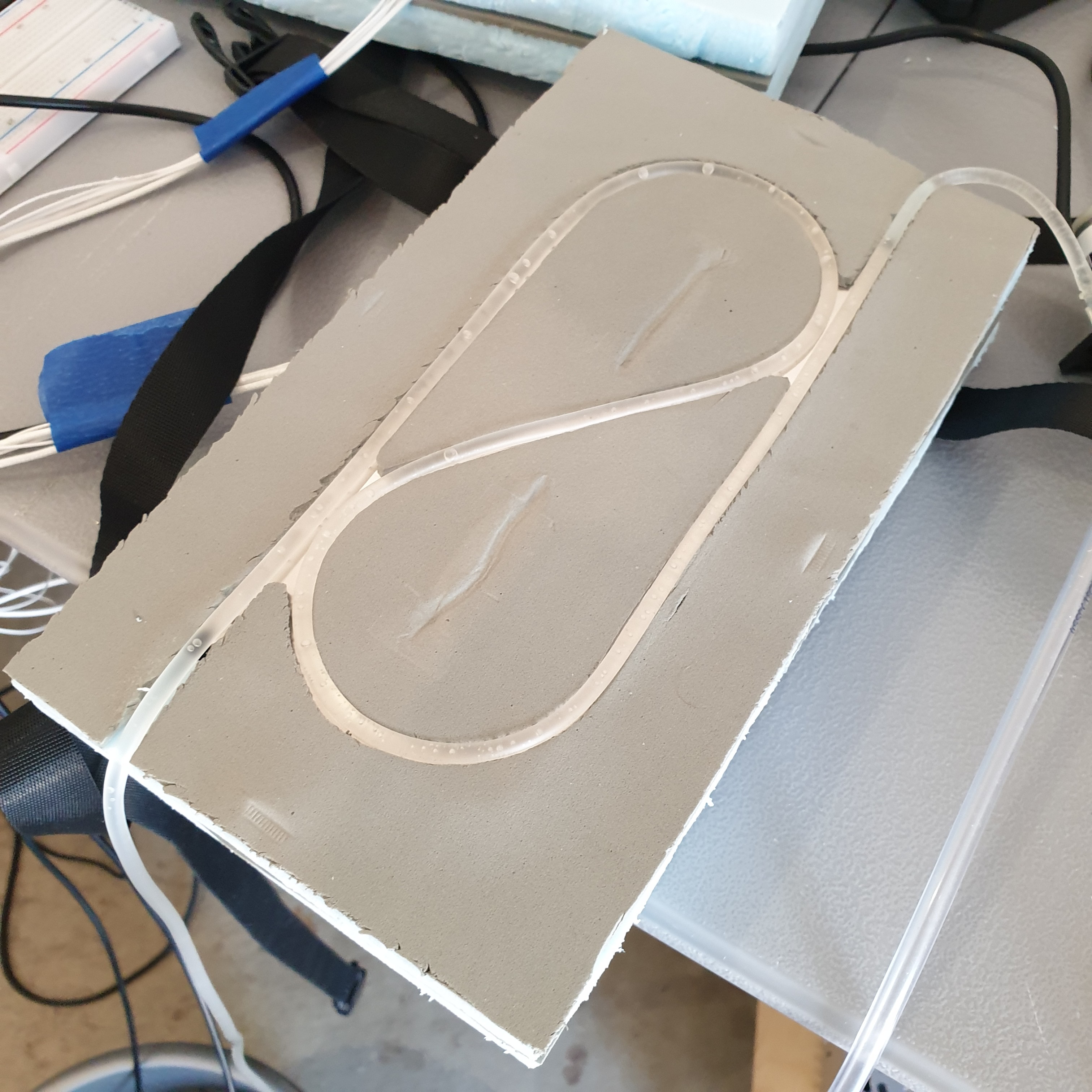

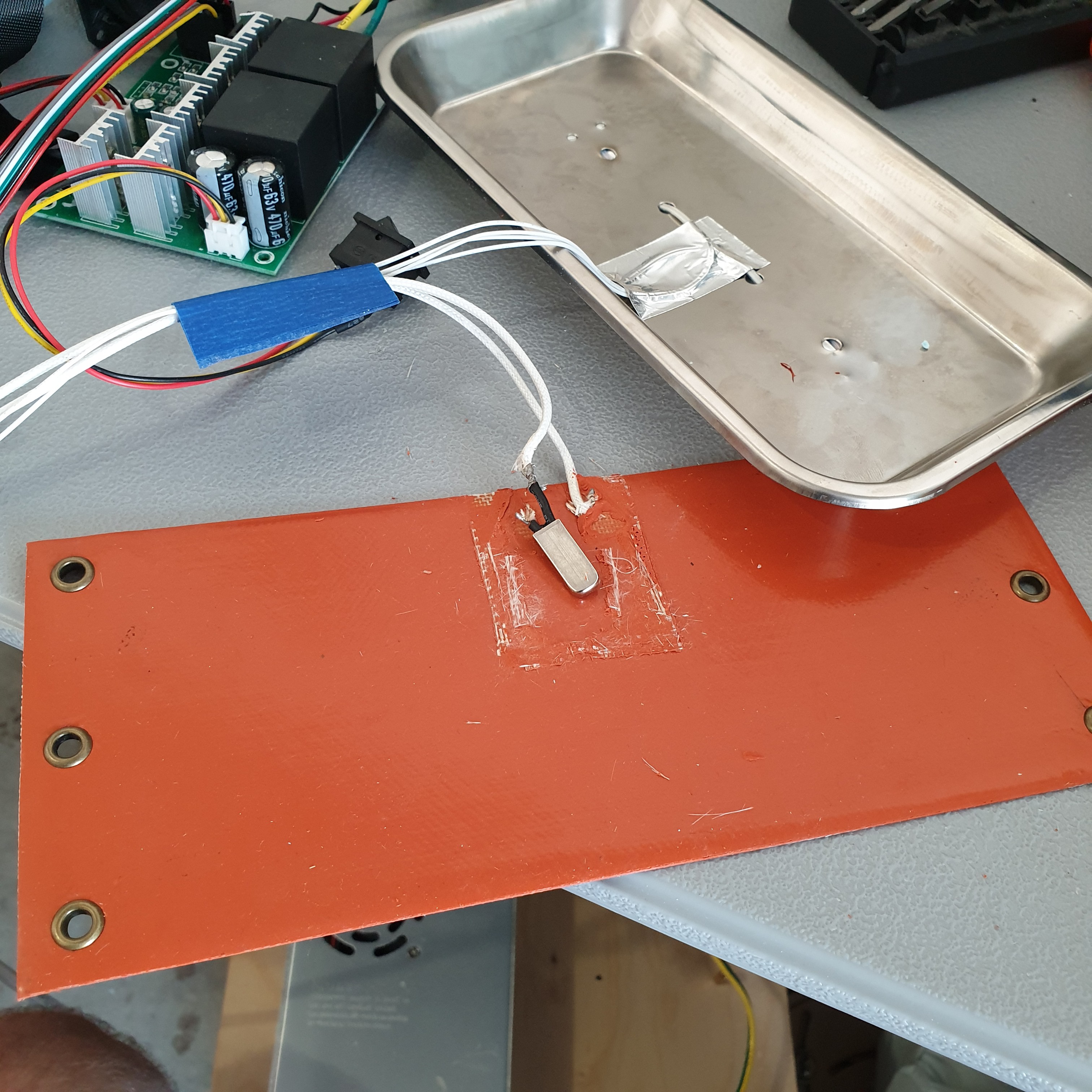

Thermal performance testing with IV tubing sandwiched between two 100W silicone heaters has continued over the last week.

I am waiting to publish test data until I make one more modification to the device. During testing I discovered that the silicone heater pads have a built-in thermostat switch that opens when the thermostat reaches 65 degC. I have since removed the thermostat so I can have more refined control over the heat generation for the next few tests.

As expected, initial tests indicate that thermal insulation of the PVC tubing greatly limits the rate of heat transfer to the fluid. The simplest solution to this would be to increase the length of tubing that is in contact with the hot plates. Unfortunately, initial results indicate that at least three times the current tubing length would need to be in contact with the hot plates to achieve the desired outlet temperature of 38 degC. Further testing without the thermostat on the heater pads may change these results.

The IV tubing I am using is from a veterinary infusion fit that I bought online. It is a PVC tubing with 3mm ID and 0.5mm wall thickness.

I put the peristaltic pump motor on a speed controller to achieve lower flow rates. Even at 50% speed, there was no significant change to the temperature rise between the inlet and outlet.

It is clear that the heater will need to be heated to a setpoint above 42 degC in order to achieve the desired fluid outlet temperature with the current device configuration. Unfortunately, 42 degC is the temperature at which hemolysis can begin to occur in red blood cell products. It is beyond the current capabilities of this test setup to determine if temperatures in excess of 42 degC are present and in contact with the fluid at heater setpoints above 42 degC.

John Opsahl

John Opsahl

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.