It's always encouraging to arrive at a promising new design concept this far into product development. It signals to me that all the work I put into developing and testing earlier prototypes (that have resemblance to commercially available IV fluid warmers) was an exercise in "learning the rules". Now that I know the rules, it's much easier to imagine new ways to break them.

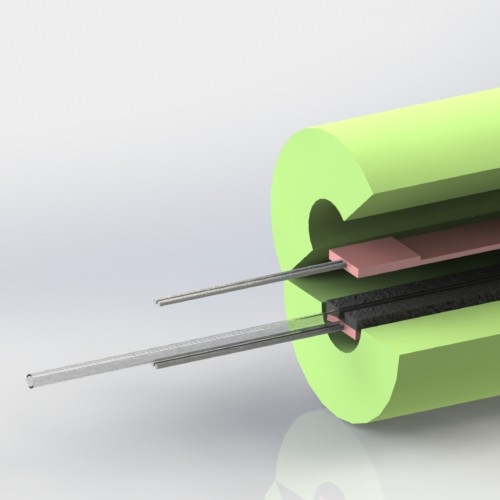

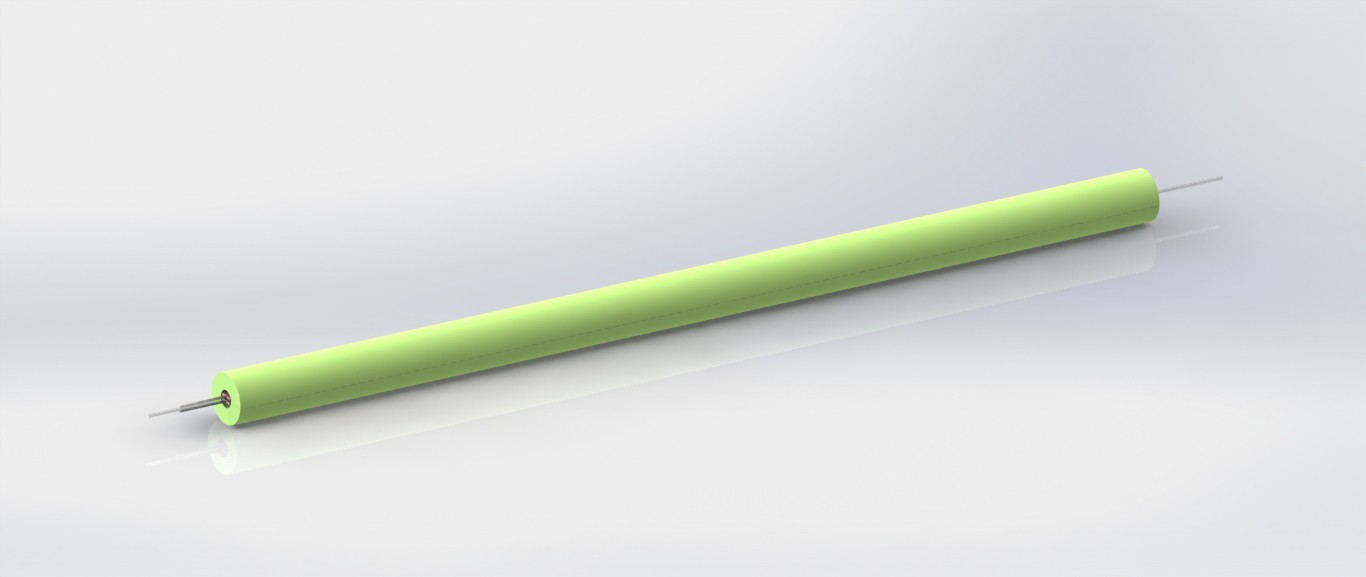

This new IV fluid warmer heat transfer concept, depicted in the images above, is my latest attempt at breaking the rules. It has potential to be cheaper and perform better thermally than the existing two hot plate design. It uses two low cost silicone pad heaters for deicing windshield wipers (didn't even know they were a thing, but they are readily available online) on two sides of the IV tube. Using these long, thin heaters results in a thermal contact area between the heater and the IV tube that is double the existing design. So potentially, these heaters do not have to be heated to as high of a set point as the existing design to achieve a similar rate of heat transfer to the fluid. While this new concept uses double the length of IV tubing, it can be bent to whatever shape is needed and allows the full length of tubing to be used (i.e. doesn't double 24in of tubing back on itself to result in only 12in of length).

It may be that using double the length of IV tubing is a deal breaker on this design, but there is always opportunity to not use the full length of the silicone heater and still achieve more thermal contact area between the heater and IV tube than the existing two hot plate design.

Heaters have already arrived. Waiting on the thermistors to arrive so I can more accurately measure heater temperature. Should have thermal test results for this late next week.

John Opsahl

John Opsahl

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.