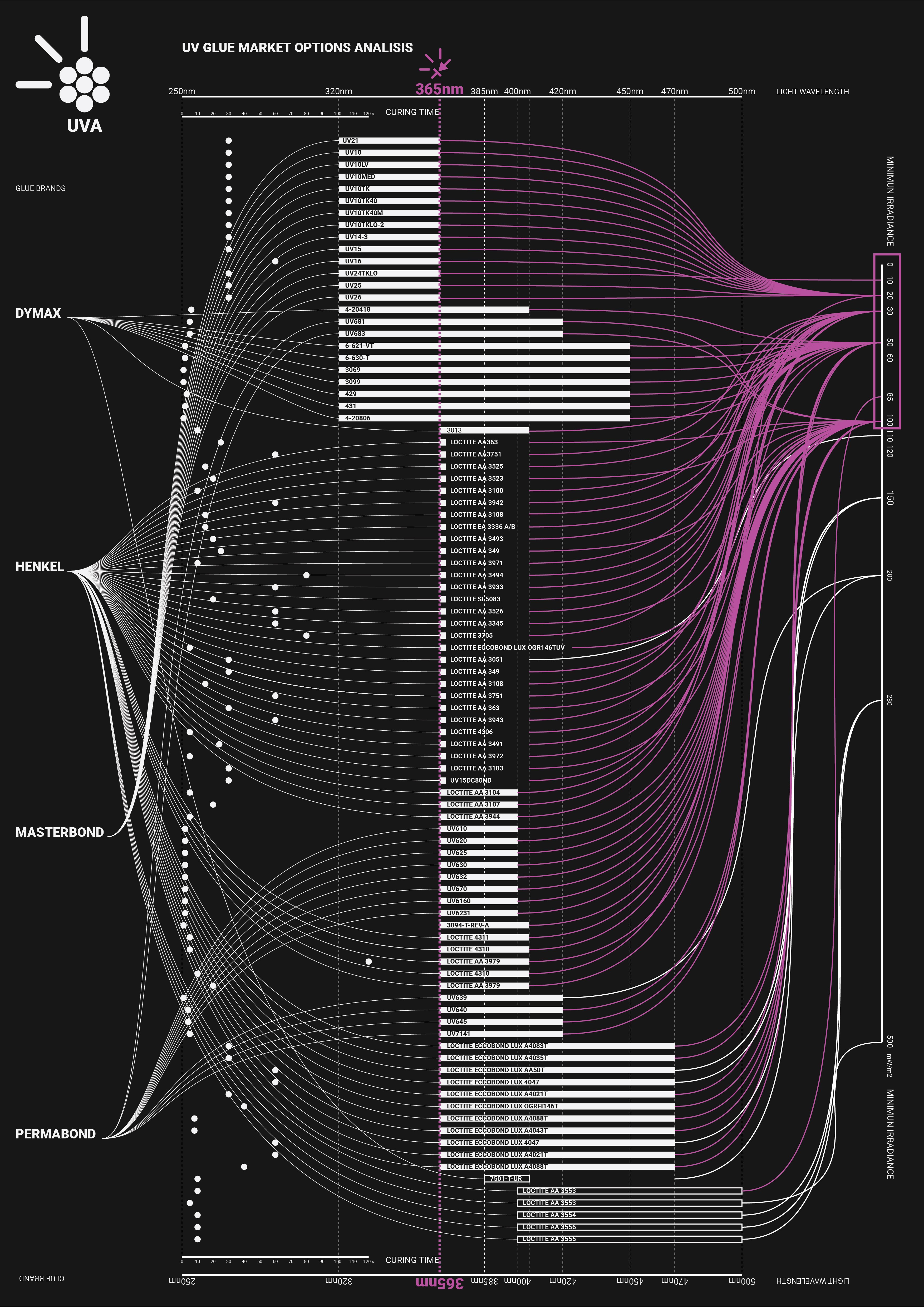

LEDs come in all manners of sizes, colors and brightness. To be able to choose the most appropriate ones, we need to know what are they going to be used for. For this purpose, we did some market research on UV curing glues. After checking the datasheets of 89 models of adhesives across 4 different companies, we came up with following graph:

The source of this information can be found in

spreadsheet format, here.

Let’s highlight some important aspects of this dataset:

- Save for

a handful of glues specifically designed to be cured by visible

light. All studied adhesives can be cured by a wavelength of 365nm.

- The large majority of datasheets recommend an irradiance of around 100 mW/cm^2 or less for ideal curing conditions. (Though the documentation can be somewhat ambiguous on the absolute minimum irradiation required to still cure the product).

- Small portion of glues from Henkel recommend using a secondary wavelength of 250nm to improve curing on surfaces exposed to oxygen. We will not be addressing this, as it would prohibitively increase the cost of the project.

From this information we can conclude that we should ideally aim for a lamp that emits 100 mW/cm^2 @ 365nm, as this gives the project the best coverage of commercially available glues. Though as we will soon see, it is not trivial to emit light at such high intensity from a battery powered device.

SELECTING THE LEDS ON MOUSER/DIGIKEY

It turns out there are not that many high power UV LEDs available in Mouser or Digikey. Even less when you search for ones that:

- Emit at 365nm

- Have high power and efficiency.

- Are inexpensive.

- Are readily available and well stocked.

- Have small viewing angles (we need a concentrated beam light to reach those 100mW/cm^2)

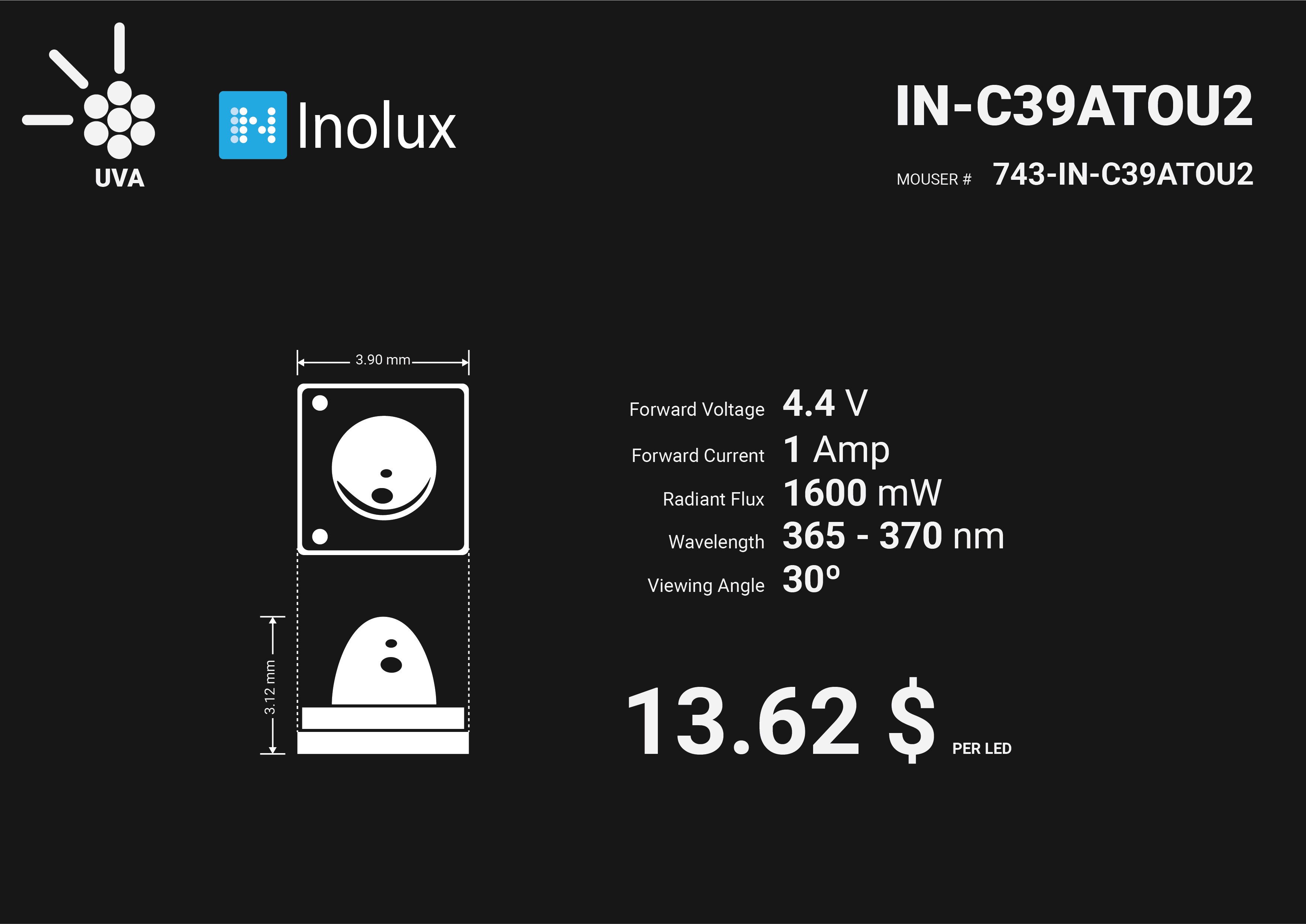

We decided on the IN-C39ATOU2 from Inolux, link to the Mouser listing here.

Some highlight of the LED are:

- Forward Voltage: 4.4V

- Forward Current: 1Amp

- Radiant Flux: 1600mW

- Wavelength: 365 – 370 nm

- Viewing Angle: 30°

- Size: 4x4mm

- Cost: 13.62 $ per led

Note: Yeah, I know that they look really expensive. But the other were not much better. UV LEDs are just really expensive.

HOW MANY LEDS DO YOU USE ?

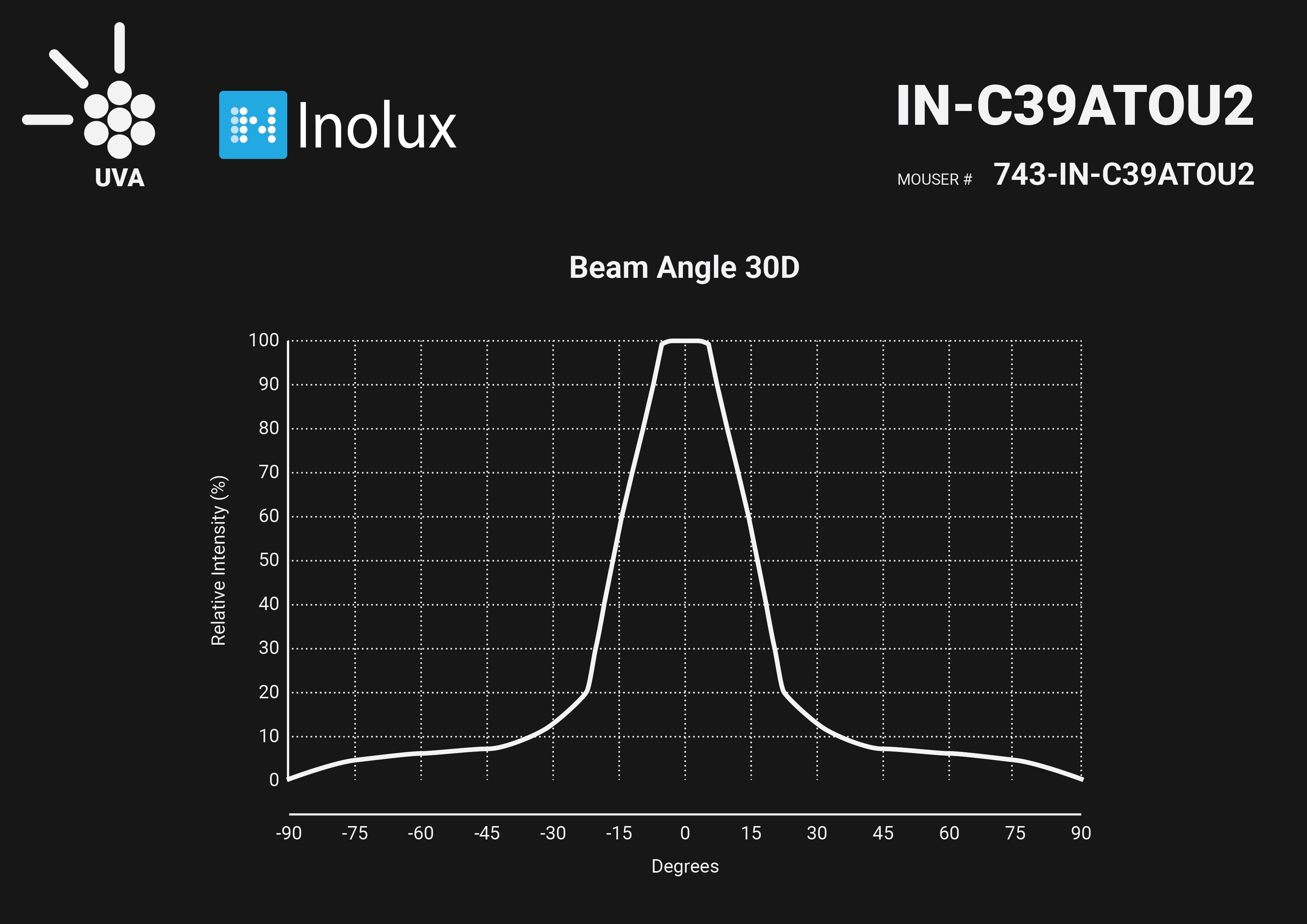

Ideally we don’t want to use more LEDs than absolutely needed, both because of the price, and to save on battery life. Thankfully the datasheet provides us with all the information needed to run a couple of simulations and figure this out. Namely, the total power emitted as light (1.6W) and the radiance pattern, which looks like this:

Image source: IN-C39ATOU2 datasheet

No we can program a small script in Python to calculate how this beam pattern would look projected over a surface, at different heights.

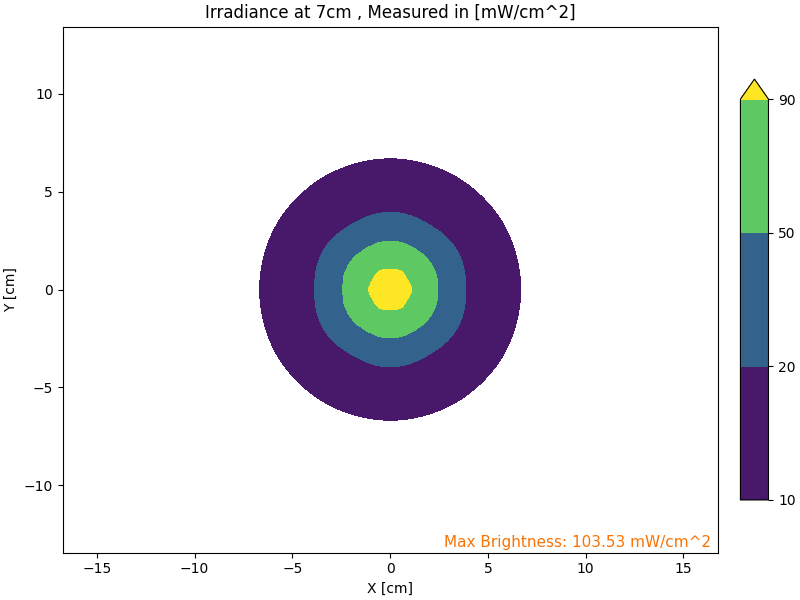

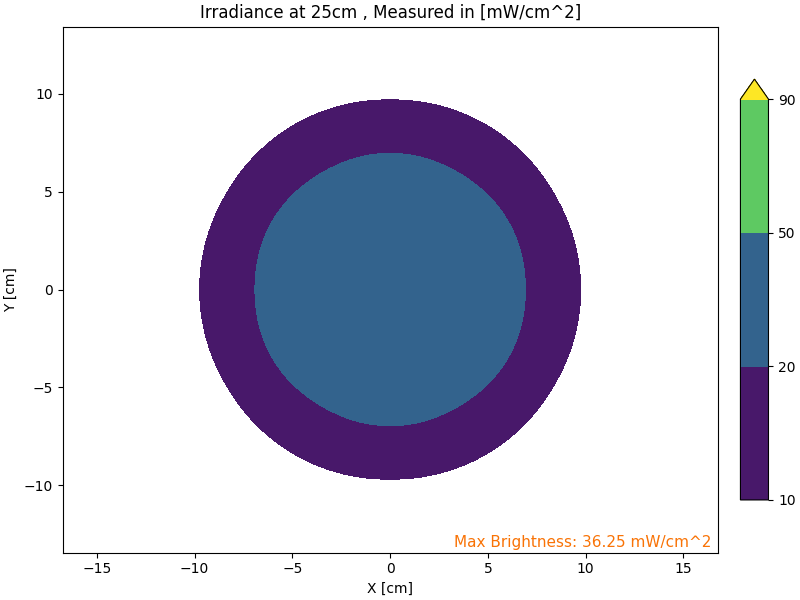

From here we can see that at its peak, 6 LEDs can indeed generate the 100mW/cm^2 we were looking for, even if it just in a small point. Now let’s look at those irradiance patterns a bit more closely:

CONCLUSION

For a total electrical power consumption of 26.4W and around 81.72$, these LEDs seem like the most sensible choice for the job. They cover both scenario, focused high intensity UV light from up close for those glues that require it. And, wide area low intensity UV light from far away for when area coverage is more important than high intensity.

EXTRA: WHY NOT USE STANDARD 5MM UV LEDS ?

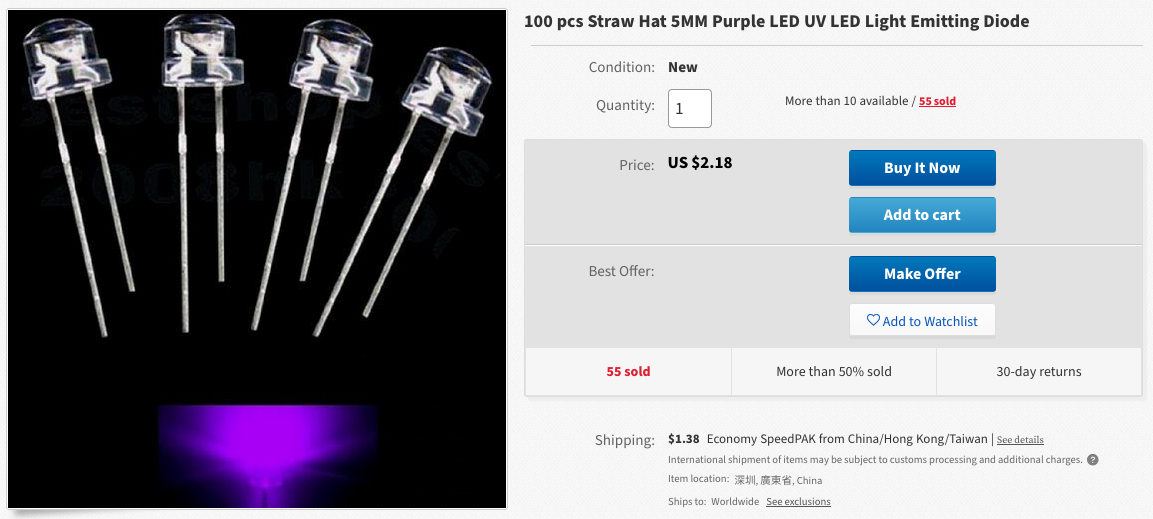

Let’s explore a fair question that might be in your mind after reading this post. If you search on Amazon or Ebay right now for “UV LED” you might find about a dozen of listing like the following, selling 100 UV LEDs for just a few USD.

Image source: Listing of UV LEDs from Ebay.

If this is so, then why pay almost a hundred dollars for just 6 LEDs? Why not use these? After all, they are not only exponentially cheaper, but are even more readily available. Which makes them even more inline with our search criteria. Well,

TL;DR:

sadly, they

just don’t work for this application.

Two main reasons for this:

- Most of these listings are for ~400nm wavelength leds. Which as we’ve seen above, don’t coincide with the activation wavelength of many of the UV curing adhesives.

- More importantly, they are very weak. So weak in fact that they might not even be able to cure anything but the most sensitive of glues.

Now,

let’s back

up

this claim by running some simulations. It’s hard to find

datasheets for these cheap LEDs,

so

instead we are going to use the data from a similar well documented

LED to feed the simulation. Namely, the UV5TZ-390-30 from Bivar (Link to the Mouser listing here)

.Image source: Mouser listing for the UV5TZ-390-30

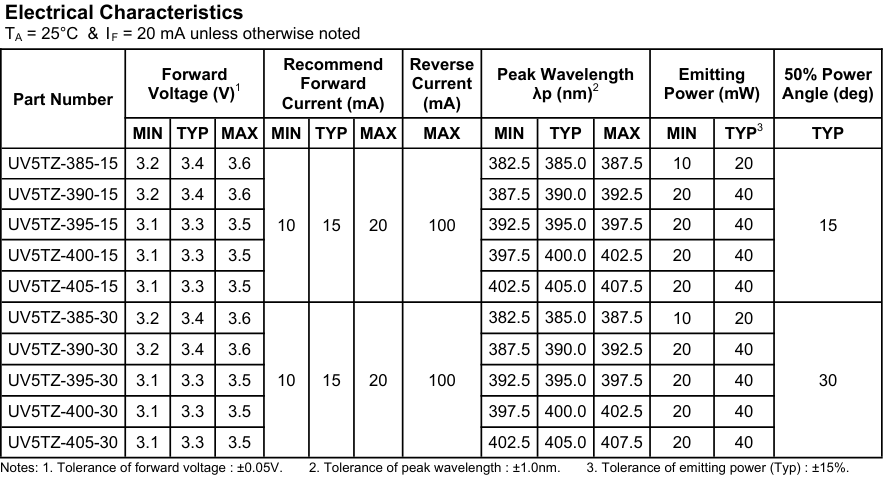

.Image source: Mouser listing for the UV5TZ-390-30According to its datasheet, at maximum power this led can produce 40mW of light with a viewing angle of 30°. As seen below.

.Image source: UV5TZ-390-30 datasheet

.Image source: UV5TZ-390-30 datasheetTo give it the best possible chance we are going to simulate a 7x7 grid of LEDs, for a total of 49 emitters working at maximum power.

There we can see that even at the point of peak irradiance, this array of LEDs is just barely able to reach 10 mW/cm^2.

Therefore, as attractive as their price seems, they are not suited for this application. As even if they had the correct wavelength for UV glue curing, they don’t output enough power to be effective at this task.

Said Alvarado Marin

Said Alvarado Marin

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

The simulation program looks well done and incredibly useful. Is there a source for the simulation program?

Are you sure? yes | no