-

Color Commentary on Color Rendering Index

09/02/2020 at 07:00 • 0 commentsAlthough the earlier logs regarding phosphors suggest that fluorescent and LED sources can be manipulated from relatively monochromatic emitters of photons into producers of white light, the quality of that white light must be quantified given the distinctive construction of its constituent color spectrum. Lacking the relatively smooth and continuous energy band of wavelengths associated with incandescent sources results in a performance difference as it relates to color rendering. A metric for this performance is the Color Rendering Index or CRI and ranges from 0 for a monochromatic source to 100 for incandescent sources (with typical values for LED and fluorescent light sources ranging from 80-90)1. The efficacy of a light source can be significantly benefited by limiting its energy output to a finite number of wavelengths, allowing the light to appear white while only generating a fraction of the wavelengths associated with the incandescent spectrum. However, the capacity of such a light to produce acceptable color rendering is a trade-off which has to also be taken into consideration.

As documented in the first project log about color temperature, the color temperature of the light source defines the peak of the energy curve of the associated light spectrum. Lower color temperature light sources accentuate lower energy light wavelengths like reds and yellows (such as the light from an incandescent filament bulb). Higher color temperature ranges transition from white to blues with 5000 Kelvin to 6500 Kelvin range sources being most closely associated with balanced white to slightly blue daylight. Note that in these cases white is meant to suggest a balance of light energy as perceived for each wavelength. Lower temperatures (2000-3000 K) are typically described as warm, temperatures around 5000 Kelvin are labeled as daylight, and even higher temperatures (≥6500 K) are labeled as cool.

These two metrics are important to consider in unison since CRI only measures the conformance of a source’s color rendering performance to that of an incandescent source of the same color temperature. However, the different color temperatures have naturally different impacts upon the way colors appear to the human eye. The example obvious to most would be the warm light visible when the sun is at the horizon (typically rated at 2300 K) versus the sun in the noon sky (5000 K). The strong presence of red wavelengths emanating from a 2300 Kelvin source would suggest that a white (or any other) object would naturally appear more reddish regardless of the rated CRI. The CRI can identify the possibility of unintended color shifts for any given source at a specified color temperature when compared to a source of a different type at the same rated color temperature. However, the CRI does not preclude the presence of color shifts which are a function of a given color temperature. At the same time, personal preferences and historically established expectations may ensure demand for lighting options at every color temperature range.

If CRI is a primary distinction to be overcome between efficient lighting sources and the incandescent sources they replace what other drivers exist to maximize color performance? Well that will be a great subject to tackle in the next project log!

1 Color Rendering Index (CRI) Explained.” Full Spectrum Solutions, Full Spectrum Solutions, Inc., 2 Aug. 2017, www.fullspectrumsolutions.com/cri_explained.htm.

-

Finally Shining a Light on LEDs

09/02/2020 at 06:35 • 0 commentsSo having previously reviewed incandescent light and fluorescent light sources, now would be as good a time as any for a log entry about Light Emitting Diodes (LEDs).

As with fluorescent lamps, LEDs are light sources which generate their output through luminescence. Diodes are a fundamental semiconductor device which allow current to pass in one direction through its terminals while preventing flow in the other direction1. This flow in what is termed the forward direction will only occur at a minimum voltage threshold defined for a given diode based upon its design characteristics. The defining material characteristics are somewhat beyond the scope of a simple project log, but suffice it to say that an LED is a diode constructed with selected semiconductor materials and specific impurities such that as current flows through an LED electrons will cross a positive-negative or p-n junction where they will fall to a lower energy level (this property is common to all diodes). The difference in the energy level of the electron as it crosses the p-n junction is released, in part, in the form of heat. However, in the case of LEDs this energy level difference is specifically engineered such that the release can also include photons of a specific wavelength. The result is that LEDs are a source of nearly monochromatic light. LEDs experience losses to heat as a side-effect of the flow of current through the device, but this is a far cry from incandescent which were in an earlier log shown to more efficiently radiate heat as infrared than any other part of their visible spectrum. The exact LED output wavelength can be tailored based upon material selection2. Rather than being limited to a couple of ultraviolet emission bands as defined by mercury plasma emissions in a fluorescent, an individual LED can be engineered for an output wavelength along the light spectrum from infrared to ultraviolet and points in between all based upon the selection and combination of appropriate component materials.

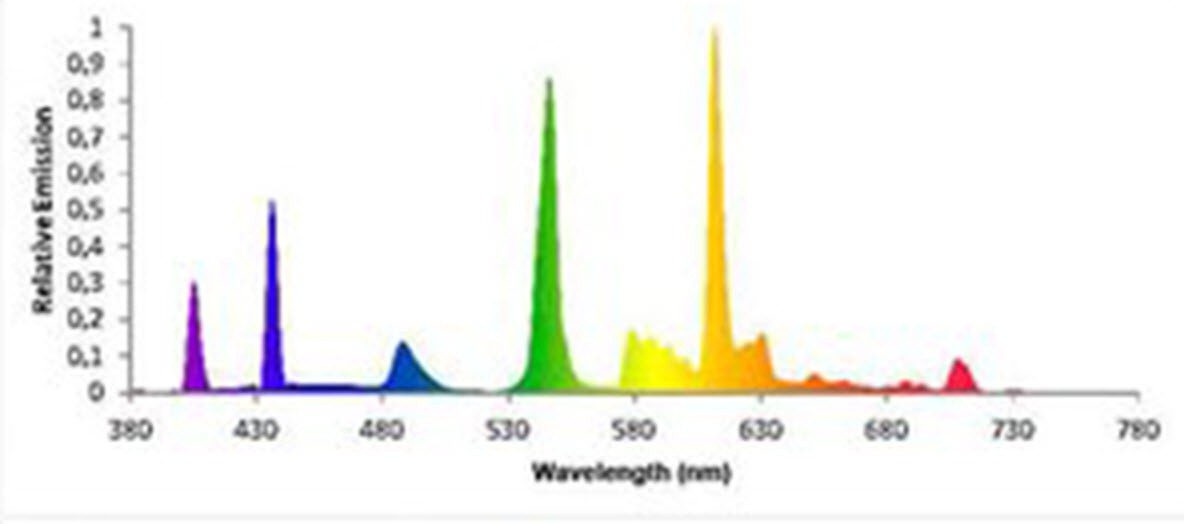

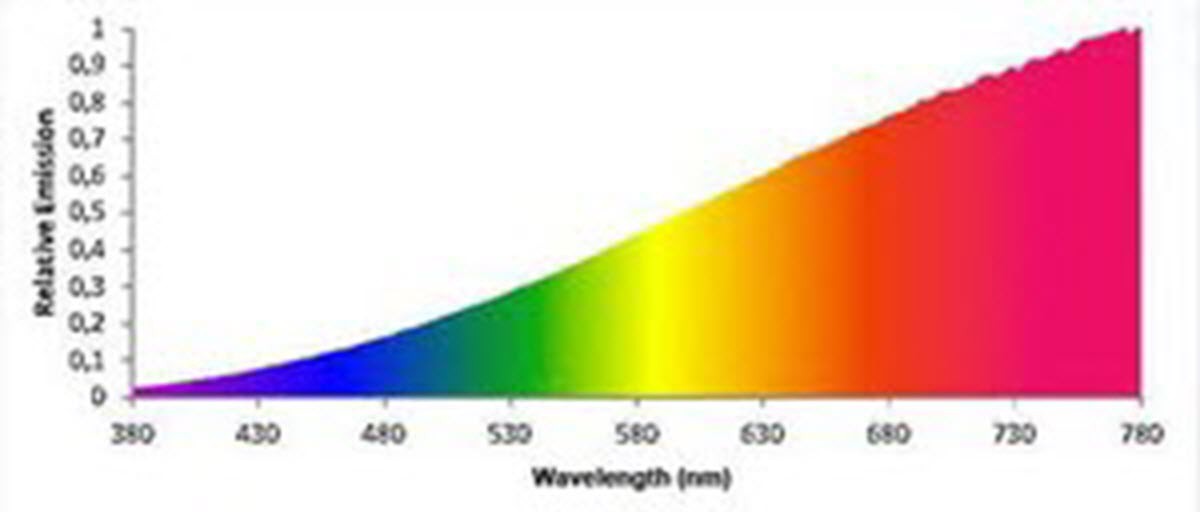

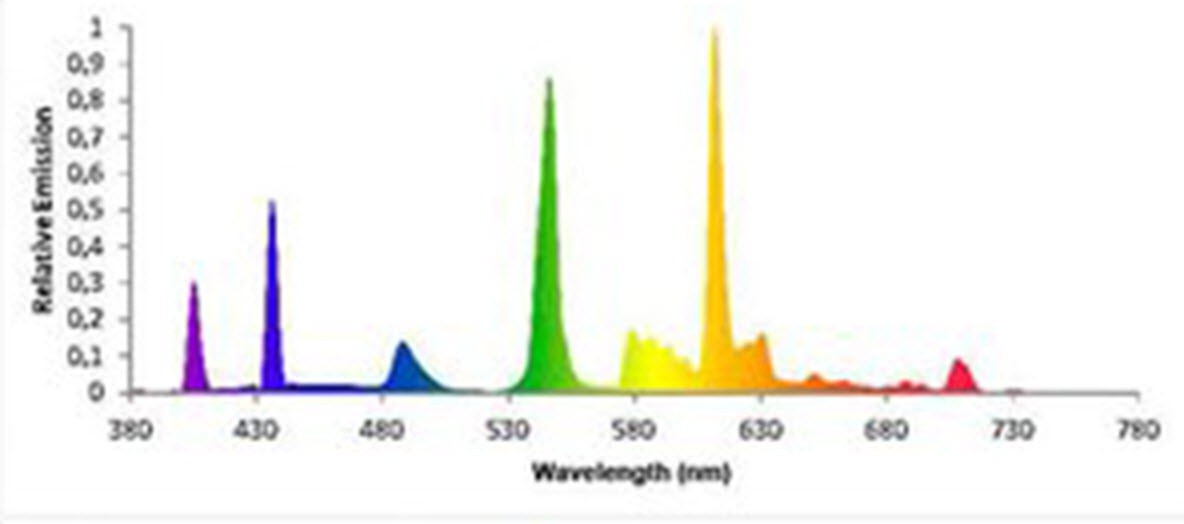

Although LED light sources can be tuned to produce light at lower energy levels within the visible spectrum, the most common white light LED design incorporates a blue LED and an associated yellow phosphor. The yellow phosphor is designed to emit a broad spectrum of visible light including reds, greens, and yellows. Some of the source blue LED light is intentionally allowed through the phosphor material resulting in a white light with color rendering performance often meeting or exceeding earlier fluorescent bulbs. The solution is simply termed a phosphor-coated LED. Despite both being monochromatic sources with a phosphor-expanded spectrum, note the differences between fluorescent and LED source outputs below.

![]()

![]()

Normalized visible light spectrum energy output of a typical fluorescent.5 Normalized visible light spectrum energy output of a typical LED.5 The most encouraging news regarding phosphors is that decades of research has made sure that the quantum efficiencies of current phosphors on the market can be more than 90% (but not yet exceeding unity in the visible spectrum)3. However, the conversion of a photon of energy from a higher wavelength to a lower wavelength results in a loss of energy which can significantly limit the maximum total efficacy of the system. In the case of fluorescent lamps the maximum system efficiency assuming no other losses could be roughly estimated by the ratio of the emitted wavelength (254 nm) to that of mean wavelength of visible light (550 nm)4. Based upon an ideal white light source as referenced in an earlier log (250 lumens per watt), fluorescent lights sources would be capped to around 115 lumens per watt. In fact, the highest efficacy noted for any fluorescent system is indeed around 100 lumens per watt. Unfortunately, compact fluorescent lamps compromised this peak efficacy through design modifications such as smaller tube diameters which generally reduced their efficacy to no more than 70 lumens per watt. Phosphor-coated LEDs possess an advantage here because their selected output wavelength is much longer, with blue LEDs commonly operating at the 460-nm wavelength. Although other factors contributing to overall efficiency, aka wall-plug efficiency, will normally factor into a consideration this fundamental difference in favor of LED-based designs is the reason that LED efficiencies of >200 lumens per watt are considered within reach.

Note that all of the LED light sources selected for this project are rated for over 90 lumens per watt. This was not an intentional selection in favor of high-efficiency designs, but rather reflects the general state of the current retail LED market. Even more impressive is that some of these choices do so while providing a claimed 90+ CRI (efficiency and color spectrum/rendering represent typical trade-offs in a commercial light source). This single data point is perhaps one of the biggest factors among many which has driven the rapid standardization towards LEDs as the preferred efficient lighting source.

Having discussed the fundamentals of artificial light generation, and in particular having highlighted some of the significant advantages presented by LED light sources, the next project logs will cover other key concepts at play in this project proposal. Specifically, both color temperature and Color Rendering Index will both receive further examination. The log entries should highlight the limitations of current LED sources while also establishing the team's interest in developing a solution around commodity LED lamps vs. a custom-built LED solution.

1 Stevenson, Richard. “The LED’s Dark Secret.” IEEE Spectrum: Technology, Engineering, and Science News, IEEE Spectrum, 1 Aug. 2009, spectrum.ieee.org/semiconductors/optoelectronics/the-leds-dark-secret.

2 Scully, Taylor. “Everything about LEDs: Learn the Basics of LED Lighting and How to Power!” LEDSupply BLOG, LED Supply, 11 Mar. 2015, www.ledsupply.com/blog/what-you-need-to-know-about-leds/.

3 Kane, Raymond, and Heinz Sell. Revolution in Lamps: A Chronicle of 50 Years of Progress. Fairmont Press, 2001.

4 Ronda, Cornelis R. Luminescence: from Theory to Applications. Wiley-VCH, 2008.

5 “Efficiency of LEDs: The Highest Luminous Efficacy of a White LED.” DIAL, DIAL GmbH, 4 Aug. 2017, www.dial.de/en/blog/article/efficiency-of-ledsthe-highest-luminous-efficacy-of-a-white-led/.

-

Talking Tubes (Fluorescent Lamps Worth a Review)

08/31/2020 at 13:03 • 0 commentsThis entry will differentiate the light output of fluorescent sources from incandescent lights. Highlighting these distinctions is a valuable step even for a project built upon LED lighting. Although primary light generation in an LED light source is completely distinct from that of either incandescents or fluorescents, the similarities LED light sources share with fluorescents are strong enough to justify an examination of the unique properties of fluorescent lamps. Let's review!

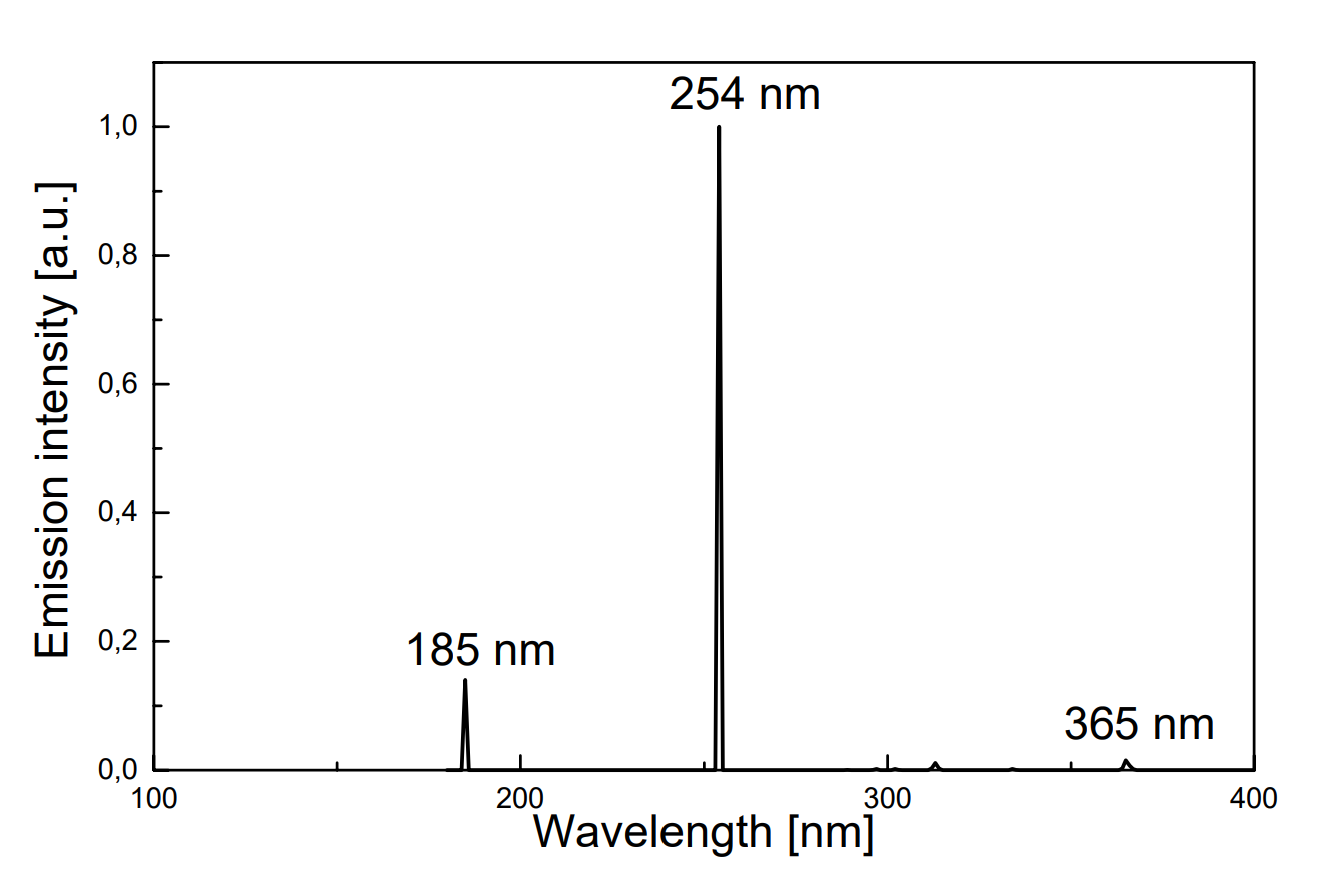

Fluorescent light sources generate radiation through a completely different mechanism from incandescent filament bulbs and produce a radiation output spectrum which is also distinct. Fluorescent lamps are a gas discharge light source in which an electrical voltage excites mercury vapor in a low-pressure tube. This excitation results in the promotion of electrons within the mercury atoms temporarily to higher levels of energy. When those electrons return to their normal state energy is released in the form of photons at specific energy levels or wavelengths. These are notable in the case of mercury for being in the ultraviolet spectrum. Rather than a continuous spectrum of wavelengths, fluorescent lamps instead exhibit an output radiation spectrum with peaks at a few wavelengths in the invisible UV range1 (see the figures below). This process, distinct from the emission of light through heating which defines incandescence, is known as luminescence.

![]()

![]()

Normalized visible light spectrum energy output of a typical halogen incandescent source.4 Normalized (internal) output spectrum of a mercury vapor fluorescent (all peaks in UV).5 At this point fluorescent sources have been defined by the method through which they convert electrons into photons. However, what has been reserved until now is the ultimate method by which these sources produce white light given the limited spectra output relative to the continuous band emitted by sources like the sun. For fluorescent sources the simple answer is phosphors. Through the process of photoluminescence substances known as phosphors, typically composed of various inorganic compounds in combination with rare earth metals, are used to absorb energy output by LED and fluorescent sources and convert them into lower energy wavelengths2. For fluorescent light sources this is critically important since the lamp must minimize the amount of UV radiation emitted to keep UV output within safe limits. Early fluorescent phosphors admitted UV photons and radiated visible light in the blue and orange parts of the visible spectrum. This light output (figure below) effectively produces a white light source but its associated color spectrum differs significantly from that of incandescent sources and drives a worthwhile discussion on the color rendering performance of the light (reserved for a later post). More modern fluorescent phosphor formulations known as triphosphors emit visible light in the blue, green, and red areas of the spectrum with an associated improvement in color rendering (usually requiring an increase in cost and complexity of manufacture)3.

![]()

Normalized visible light spectrum energy output of a typical fluorescent.4

LEDs present a slightly different opportunity since their light source is materially different and, as such, are worth a separate post!

1 Schubert, Fred. Light Emitting Diodes. 2nd ed.

2 Jones, Eric D. “Light Emitting Diodes (LEDS) for General Illumination: a OIDA Technology Roadmap.” Mar. 2001.

3 “How Is White Light Made with LEDs? | LED Lighting Systems | Lighting Answers | NLPIP.” Lighting Research Center, Rensselaer Polytechnic Institute, 2003, www.lrc.rpi.edu/programs/nlpip/lightinganswers/led/whiteLight.asp.

4 “Efficiency of LEDs: The Highest Luminous Efficacy of a White LED.” DIAL, DIAL GmbH, 4 Aug. 2017, www.dial.de/en/blog/article/efficiency-of-ledsthe-highest-luminous-efficacy-of-a-white-led/.

5 Jüstel, Thomas. “Fluorescent Lamp Phosphors: Is There Still News?” Mar. 2007, www.fh-muenster.de/ciw/downloads/personal/juestel/juestel/Fluorescent_Lamp_Phosphors-PGS-050307.pdf

-

Talking Temperature (of a Light Source)

08/31/2020 at 12:21 • 0 commentsA key concept at the heart of this project is that of color temperature. As such, allow for this short introduction to the history of the concept. Future entries may further elaborate on the complexities associated with this metric, but the following should provide at least a basic introduction to how this terminology has become a core component of the discussion when talking about light sources.

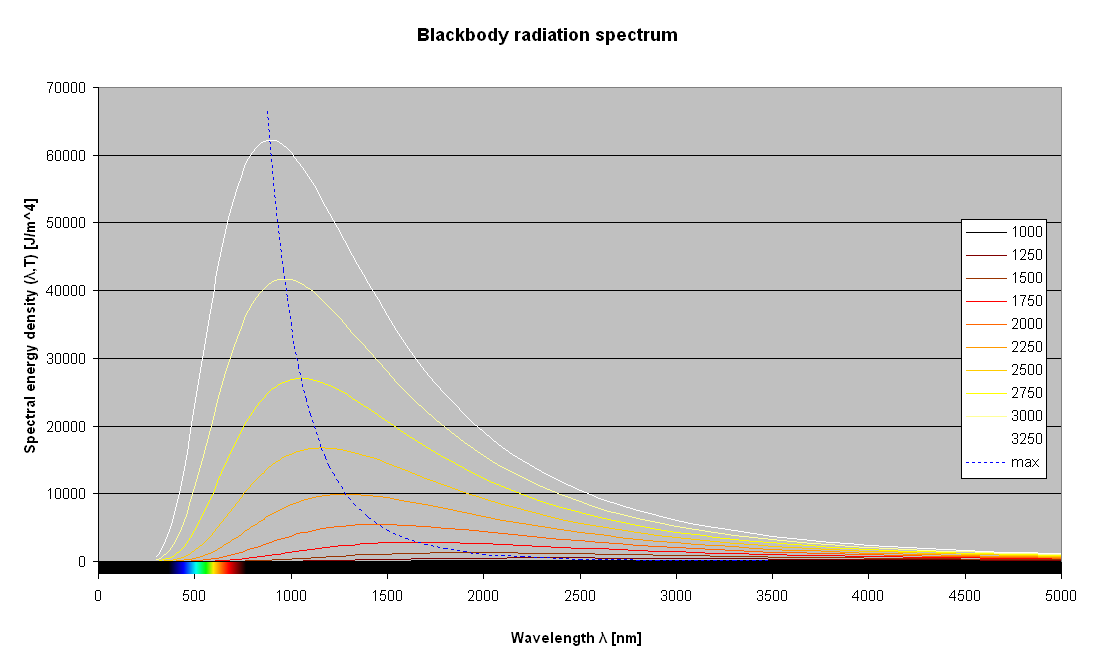

Electric light sources had existed in different forms prior to the commercialization of the tungsten filament incandescent light bulb around the start of the 20th century. However, the continuing presence of incandescent bulbs over a century after their initial popularization underscores the importance of understanding their basic operation and critical drawbacks. The basic construction of traditional light bulbs incorporates a glass enclosure which contains a filament wire connected to electrical contacts in a base. The glass enclosure is evacuated and typically filled with an inert gas. The filament materials are selected and constructed to provide a targeted amount of resistance when connected to a source of electricity. The most common material associated with filament bulbs is tungsten, but early models used carbon filaments. The result is that when connected to an electrical source current passes through the filament such that it is heated to a target temperature. Once heated the filament will glow, or incandesce, per a relationship between an object’s associated temperature and the total energy of radiation emitted as well as the color of visible light emitted. At lower temperatures, a source emits relatively low levels of total energy with a peak of the energy being in the infrared and red parts of the spectrum1. This is generally perceived as glowing red hot. However, as the object is heated up more energy overall is emitted and the spectrum includes more components of the visible spectrum (generally composed of wavelengths of light between 400 nm to 700 nm). An object reaching these higher temperatures is generally perceived as glowing white hot. Color temperature defines the wavelength at which the peak energy is emitted and as such is directly associated with the relative balances of energy for each of the wavelengths of visible light. Note in the figure below how only a small section of the wavelengths (marked on the left) include the visible light spectrum.

![]()

The energy curve for each temperature demonstrates that invisible infrared wavelengths (> 700 nm) represent most emitted radiation for incandescent sources. Visible light wavelentghs are highlighted by the color rainbow on the left. The peak energy wavelength decreases as the temperature of the source increases. Diagram excerpted from Iacopo Giangrandi's "Black Body Radiation and Color Temperature."1 The primary advantage of such a light source is that it is comparable to the light emitted from the sun. Although not seemingly related, both an incandescent light bulb2 and the sun generate light though heating3. The spectrum of light produced includes the continuous spectrum of light wavelengths across the entire visible spectrum. The significant disadvantage of such sources is that radiation generated typically includes a significant component of wavelengths outside of the visible light spectrum. In the case of incandescent bulbs, although essentially 100% of input power translates to output energy only 6% of that energy is within the visible spectrum4. A disproportionate amount of power input is converted into invisible infrared energy which is perceived as heat radiating from the bulb. The efficacy of a given source is expressed in the luminous flux, a measure of the power of light radiation as perceived by the human eye, per watt. An ideal source defined based upon the 5800-degree Kelvin color temperature spectrum associated with the midday sun, but restricted to only the visible light spectrum, would possess an efficacy of 250 lumens per watt. That is reduced to 15 lumens per watt in the incandescent example presented earlier (and this is only under ideal conditions with no real-world losses). With the filament typically heated to around 2800 degrees Kelvin the tungsten incandescent lamp is more efficient at producing heat than visible light.

Of course, newer light sources introduce some significant changes in how light is generated. As such, the impacts of those changes to this metric are worth further discussion... for a later post!

1 Giangrandi, Iacopo. “Black Body Radiation and Color Temperature.” Giagrandi.ch, www.giangrandi.ch/optics/blackbody/blackbody.shtml.2 Orzel, Chad. “The Surprisingly Complicated Physics of a Light Bulb.” Forbes, Forbes Magazine, 21 May. 2015, www.forbes.com/sites/coxbusiness/2017/08/01/how-to-serve-clients-when-workers-arent-at-work/#4c9974345cfe.

3 Bahcall, John N. “How the Sun Shines.” Nobelprize.org, Nobel Media, 29 June 2000, www.nobelprize.org/nobel_prizes/themes/physics/fusion/.

4 Murphy, Tom. “Maximum Efficiency of White Light.” 31 July 2011, tmurphy.physics.ucsd.edu/.

-

Lamp Selection: Whatever You Do, Don't Call Them Bulbs!

08/31/2020 at 12:03 • 0 commentsOne of the stated goals of the project is to create a color temperature controlled light source using commodity LED lamps. With such a wide range of possibilities available in the market today two primary constraints were used to guide the team on lamp selection:

- Select for dimmable LED lamps of a type widely available at retail.

- Select lamps of multiple color temperatures to facilitate color control.

Fortunately dimmable LED lamps are indeed available from every imaginable retailer. For this project we opted to source our LED lamps from big-box home improvement stores primarily due to the wide selection available in that setting.

Selecting lamp color temperature deserves a modicum of explanation as the sources in question (at this stage) are all still fundamentally white light sources. Retail buyers will be familiar with correlated color temperature (CCT) labels on lamps by either their numerical value, expressed in degrees Kelvin and typically in a range between 2000 K and 6500 K, or by their marketing terms such as warm white (temperatures in the 2000 K range) , soft white (often used for temperatures in the 3000 K range) to cool white and daylight (referencing temperatures from 5000 K and above). Future project entries can elaborate upon the some of the meaning behind these terms.

Nonetheless, even with the constraints above the options available remained numerous so a few other considerations were selected as options which might facilitate early testing. Note that these are choices which could later be intentionally ignored as we learn more about the capacity of the system to provide a color-controlled lighting experience and also as we consider opportunities for expanded functionality from the device.

- Select for lamps of comparable lighting output (lumens).

- Select for lamps with a comparable light source structure.

The first choice meant that in theory the system would, at a minimum, allow direct switching between two or more color temperatures at an equivalent level of output. This functionality is typically limited to smart lighting or special purpose lamps/fixtures. Another functionality this should automatically enable would be a dim-to-warm experience where lower lighting levels could be tied to lower CCT values, emulating the dimming performance of older incandescent lamps. Again, this is a feature that is sometimes integrated into premium, manufacturer-specific LED lamps but is otherwise not a normal functionality associated with LED dimming.

The second choice is more complicated but was also a consideration as part of the testing phase. LED light sources are highly directional and, as such, LED lamps use all manner of methods to position LEDs and route their light output to ensure appropriate distribution of light. Typically, LED lamps designed as incandescent-replacements attempt to match the pattern of light distribution appropriate to the lamp shape (omni-directional for classic A-lamps, to highly directional for reflectors). To prevent differences between models from creating measurable differences with the testing platform one additional refinement was made to initially opt for LED filament-style lamps of comparable shape. This should hopefully minimize any differences at the sensors which might occur because of significant differences in beam shape and LED placement (though other considerations will also be made regarding sensor placement to further minimize this issue).

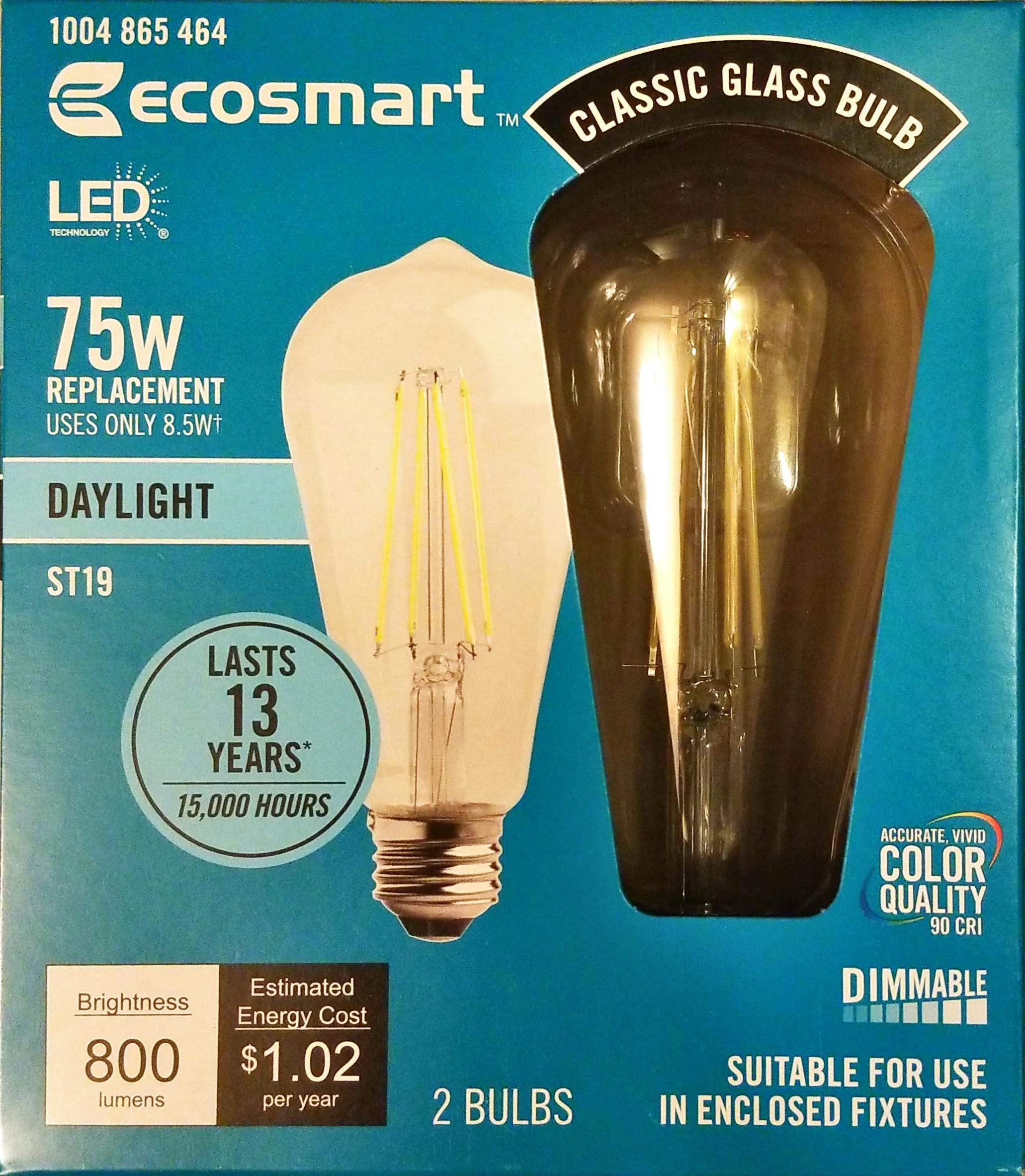

Given all of this, the following two lamps were selected as the primary range of light sources for our initial testing:

![EcoSmart Soft White ST19 EcoSmart Soft White ST19]()

![EcoSmart Daylight ST19 EcoSmart Daylight ST19]()

Soft White (2700 K) Daylight (5000 K) These lamps are relatively inexpensive if not cheap by today's standards at under $6 per individual lamp. The shape is a straight tubular design popular for vintage/retro- applications known as ST19. Note how both lamps have their LED filaments oriented in the same vertical fashion. The lamps are both rated to output 800 lumens which, though referenced as a 75 watt replacement for vintage ST19 lamps, puts them at exactly the output considered a 60 watt incandescent equivalent when discussing typical Arbitrary shape lamps (A-shape) such as the one pictured in our project banner. I'd also add that both lamps are rated at 90 CRI, which is a color rendering index. This metric is complex and worth another future project entry, but suffice it to say that these lamps should perform well at rendering colors in their associated color temperature range.

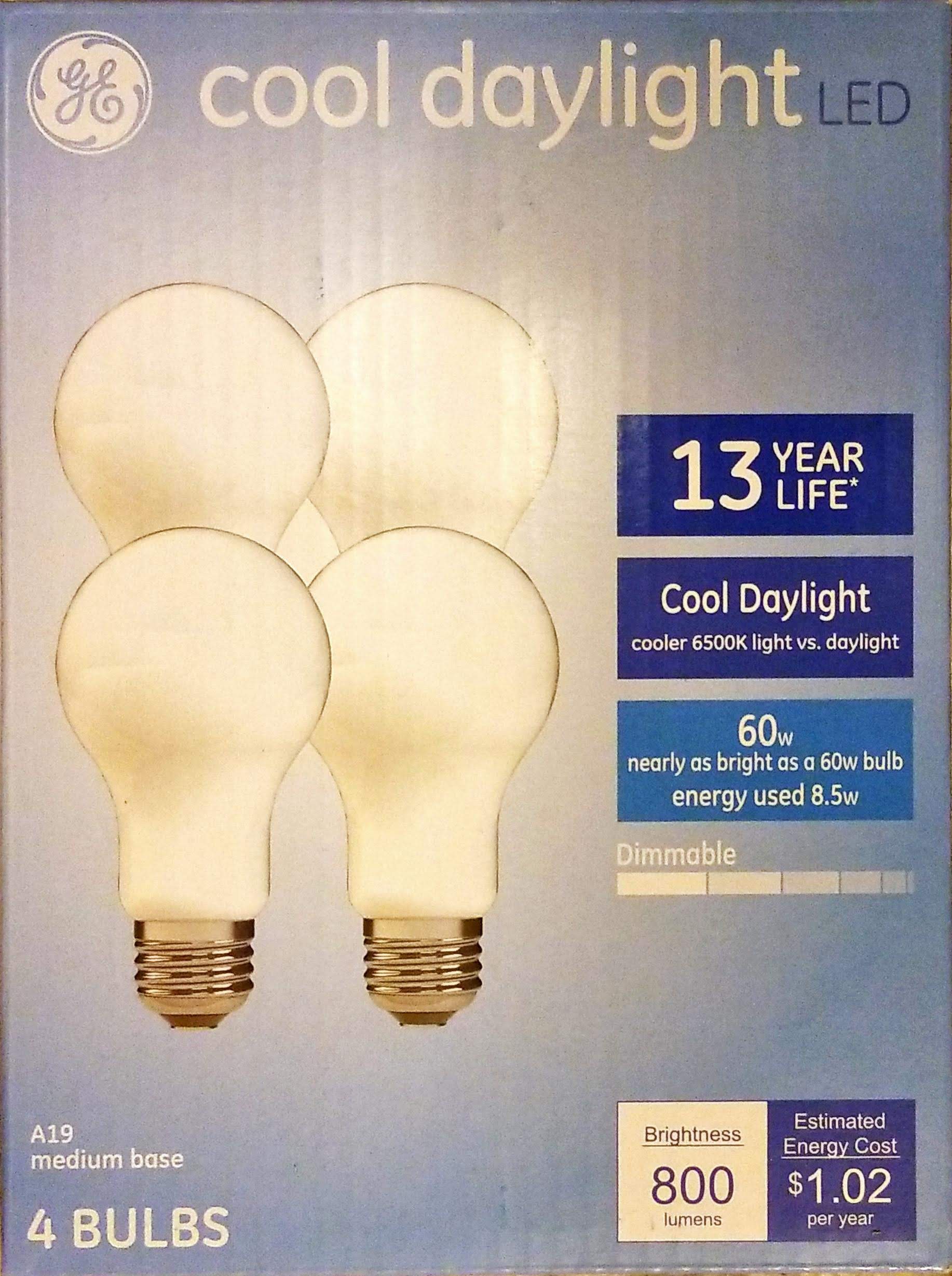

In an effort to further expand the potential range of color temperatures two additional lamps were selected at the extremes of what is available in the market:

![]()

![]()

Amber (2000 K) Daylight (6500 K) The first example is a directly comparable ST19 lamp rated at 2000 K. This lamp is comparable to the earlier choices, having a similar lumens rating, shape, and construction. The only noteworthy distinction is a lower 80 CRI (which is specific to the lamp and not necessarily relate to the lower color temperature). Note that 80 CRI is a common CRI rating for mass-market LED light sources. The 6500 K daylight lamps are a different lamp shape but close examination shows that they have a similar (if more compact) vertical LED filament positioning. Note that the cool daylight lamps are of as yet undetermined CRI, though the lack of an Energy Star rating suggests that these are likely in the typical 80 CRI range (current Energy Star ratings mandate a minimum 90+ CRI for omnidirectional lamps, explaining why so many manufacturers attempt to position replacement lamps with that rating).

Note that all the lamps above sip a mere 8.5 watts to generate their 800 lumens (compared with 50-60 watts in an incandescent source), meaning that at their maximum they are rated to output over 94 lumens per watt. One of the more interesting pieces of data which may come out of this experiment will be a measurement of efficiency changes relative to output.

Take note that an explicit effort was made to reference these devices by their industry name, lamps, rather than bulbs. As lamps these are by definition replaceable and self-contained sources in contrast to the term bulb which is typically taken to reference the glass, filament-containing end of a typical incandescent lamp. As a core purpose of this project is to create a flexible solution which could leverage devices of different types and capabilities, identifying the sources as lamps was a critical part of communicating the modular nature of this solution.

-

Designing for Speed of Implementation and (some) Safety

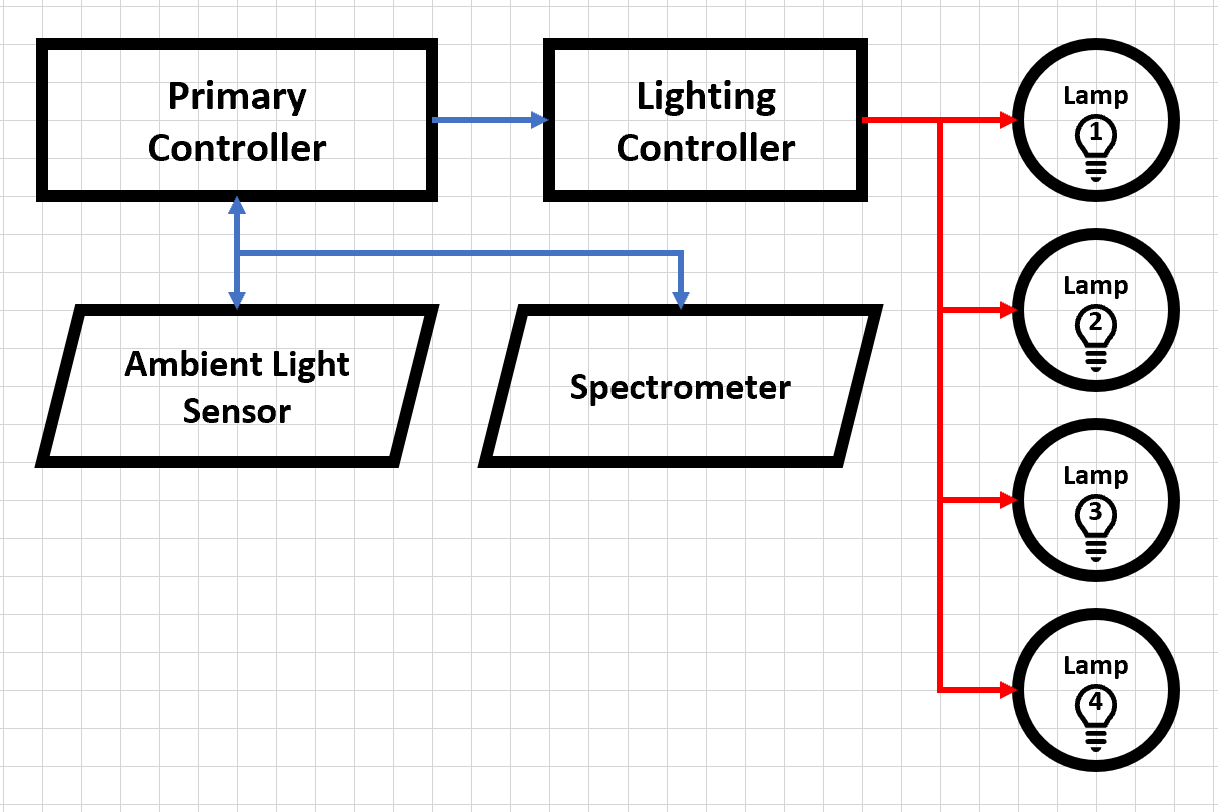

08/23/2020 at 00:03 • 0 commentsThe design choices for implementing the hardware components of this lighting concept were driven by the guiding principles of safety and speed. A simplified diagram with notes follows:

Concerns around safety meant we didn't want to be implementing too much of our own custom circuitry in this project, least of which those components which would be in contact with mains (AC) voltage. Additionally, dedicating a separate controller to lighting control as documented below would facilitate building isolation between the AC elements of the system and the other sensors.

Speed of implementation also played a role here. By using retail boards we hope to more quickly implement and test our idea by avoiding any troubleshooting which would be related to custom hardware.

Note that the design as documented below accommodates up to four independently controlled lighting channels. Though we will likely begin our testing with two channels we have designed a system capable of up to four channels to determine the benefit this could provide. One of the outcomes we may identify is the value added by a 3rd or 4th lighting source.

![]()

-

Inspiration from (superior) Hackaday Prize Competition

08/12/2020 at 16:13 • 0 commentsAllow me to use the first project log to give a big shout out to Kris Winer and his Compact, $25 Spectrometer project. I first noticed his project when it was announced as one of the 20 semifinalists of the Open Hardware Design Challenge of the 2018 Hackaday Prize (alongside my team's 2018 project entry, the Flood Fault Circuit Interrupter).

I've personally had a lifelong interest in the principles behind artificial lighting. What does that have to do with a low-cost spectrometer? Well I hope to explore that in future project logs! The short version is that spectrometers provide key insights into understanding how artificial lighting works and, specifically, what differentiates compact fluorescent lights, LED sources, and even incandescent lighting and the sun itself... not only between the different source types but also among individual examples within each category.

This project looks to leverage these differences to create a unique lighting solution using common, off-the-shelf, household LED lights. Monitoring and management of the light output level and color quality will incorporate tools including a spectrometer. This could find use in applications for efficiency, such as daylight dimming to minimize the unnecessary use artificial light, but also in human centric lighting applications where lighting can be part of a system to manage or promote productivity or circadian rhythms.

Lighting Color Control with Commodity Lamps

A controller system using consumer LED lamps to provide color temperature control and management alongside daylight dimming.

Jon

Jon