Hackaday Prize 2021 - Challenge 5 - Reactivate Wildcard

Have an idea that fits the theme, but not a specific challenge?

Well, actually...

(this log entry copied here from the contest entry)

Wildcard: to refresh or redefine the technologies we know and love in order to create a brighter future for all

A technology problem facing people today...

Although we may be getting over it, COVID-19 closures and remote learning have been pretty hard on anything that might have smelled like shop class or hands-on practical education, including opportunities to practice CNC programming and machining.

Personal 3D printing has become common. While laser cutters remain costly to own, their straightforward operation can work well as a commercial service or community resource. Meanwhile, "Subtractive" CNC milling/routing, the CAM part of CAD/CAM for 70 years, remains relatively less accessible. Obstacles include cost, space, mess, and complexity. Potential benefits of access to CNC milling include working more kinds of material with greater precision, and, for tackling the complexity, entree to a valuable career.

...and an idea of what a solution might be

This project aims to significantly reduce the entry cost of personal CNC milling by way of an apparently unprecedented combination of:

- assembly from ready parts vs. fabrication

- lowest cost

- good precision

- table-top use and shelf storage in home vs. fixed installation in garage or shop

And also some more apparently novel (?) spin-offs with wider utility:

- cheap, strong & precise linear slide mechanism

- compact screw-in-tab joint for laser cut flat parts

- cheap effective anti-backlash from laser cut flat parts and a paperclip

- cheap effective clamp from laser cut flat parts and string

- an apparently little-known but important limitation of shallow pitch lead screws

a couple of assumptions

Let's take care of this up front. The "lowest cost" premise includes a couple of assumptions -- or selection criteria for identifying circumstances where this makes sense.

- "Free” or low cost access to a laser cutter

- “Free” may mean zero or small incremental cost above a fixed cost hac/makerspace membership, school tuition, or public library millage already committed

- Commercial laser service fees may be impractical for the current design of flat parts, but there is a lot of room to optimize for quicker cutting time (a primary cost driver) and even a small quantity order can significantly reduce unit cost

- As a personal conjecture: I think it is likely that laser cutting is more accessible than shop tools like a drill press or table saw for a significant and increasing number of people

- Where different fabrication options make more sense, differently made structural parts could carry the same low cost mechanical concept of this design

- Use of a classic DremelⓇ-like handheld rotary tool.

- I propose to leave that out of the project cost because it’s a general-purpose tool that readers likely to pursue this project either already have, or can use this as the excuse they’ve been waiting for to get one

- The tool clamp may be adapted for tool shapes that differ from the classic DremelⓇ cylinder profile with 1⅞" & 2" diameters and trunnion-like brush bosses

- I have parts to try an idea for making a low cost high speed spindle of similar laser cut construction, but haven't actually tried it yet

Say what‽

"apparently unprecedented"

I’ve been logging work on this project on Hackaday.io for about a year and posted an Instructable about five months ago. Both sites have drawn 10k± views and so far no one has mentioned a similar precedent. Please comment if you know of one, or eleven.

"assembly from ready parts vs. fabrication"

Certainly many people have made very low cost CNC machines from scavenged parts, scrap materials, an equipped shop, and a fair idea of what they were aiming for.

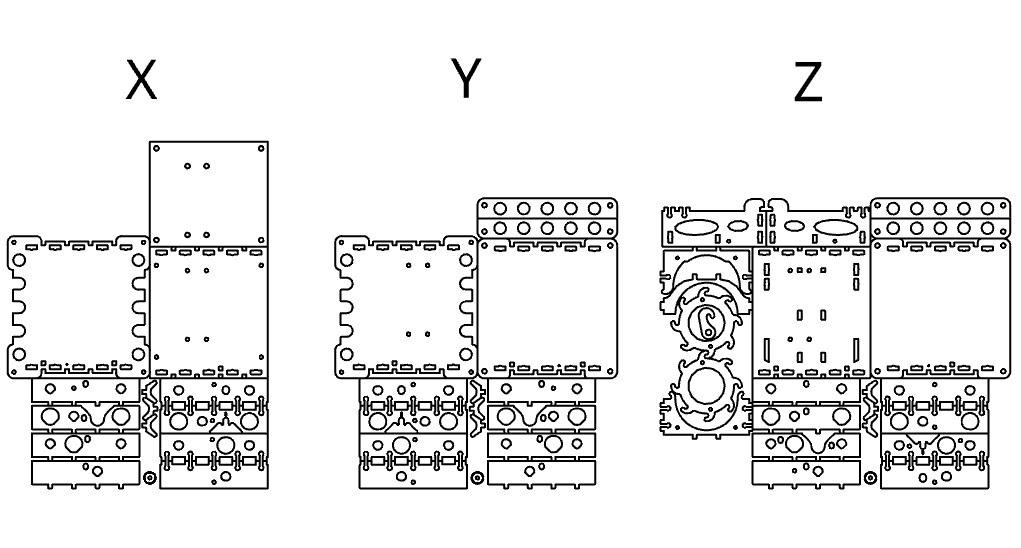

This project presents a design based on two main assemblies – the X+Y axes, and the Z axis+tool clamp – built from a few specified hardware parts and some laser cut flat pieces following detailed illustrated assembly instructions. The frame that holds the Z axis over the X+Y axes does call for ad hoc construction from available material, but that can be made to eyeball precision from practically any rigid flat-ish material and would not benefit from over-specification.

"lowest cost"

Let’s say “under US$100” to allow for whatever I’m forgetting. All parts and material used in the 3-axis motion mechanics can be ordered or bought locally in my part of the US for under US$50 (+tax) - verified October 2021. About 20% of that – US$10 for 6mm steel rods – may be scavenged from many kinds of discarded printers, copiers, etc. A complete kit of electronics costs about US$10 plus a power supply which may be something like a repurposed laptop power brick. Maybe add a little for wiring incidentals if not already at hand. I made the first machine frame from garbage-grade scraps and 8 drywall screws. A 10 piece lot of 1mm end mill bits costs <US$10.

For comparison, the lowest cost I’ve found for the most extremely cost-reduced version the generic “3018”-type 3-axis machine that I’ve found was about US$100, delivering less precision for more money. Better built “3018”-type machines for $200 or $300 still show less precise circuit board milling among results that I’ve found published by others.

As already stated, I’m assuming access to a laser cutter and a rotary tool.

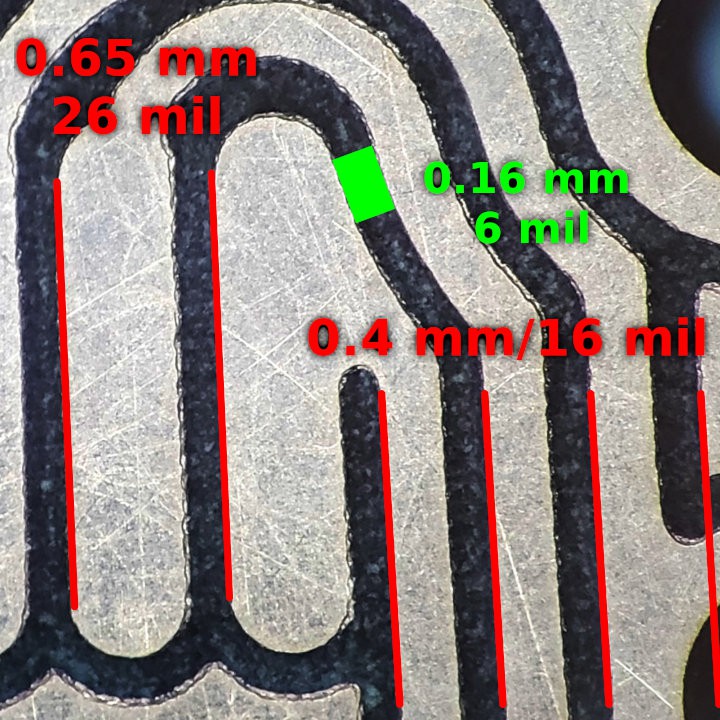

"good precision"

While not big or strong, this design does turn out pretty good precision.

- In Hackaday podcast 136, @Mike Szczys & @Elliot Williams comment:

- Yeah, right. Show me...

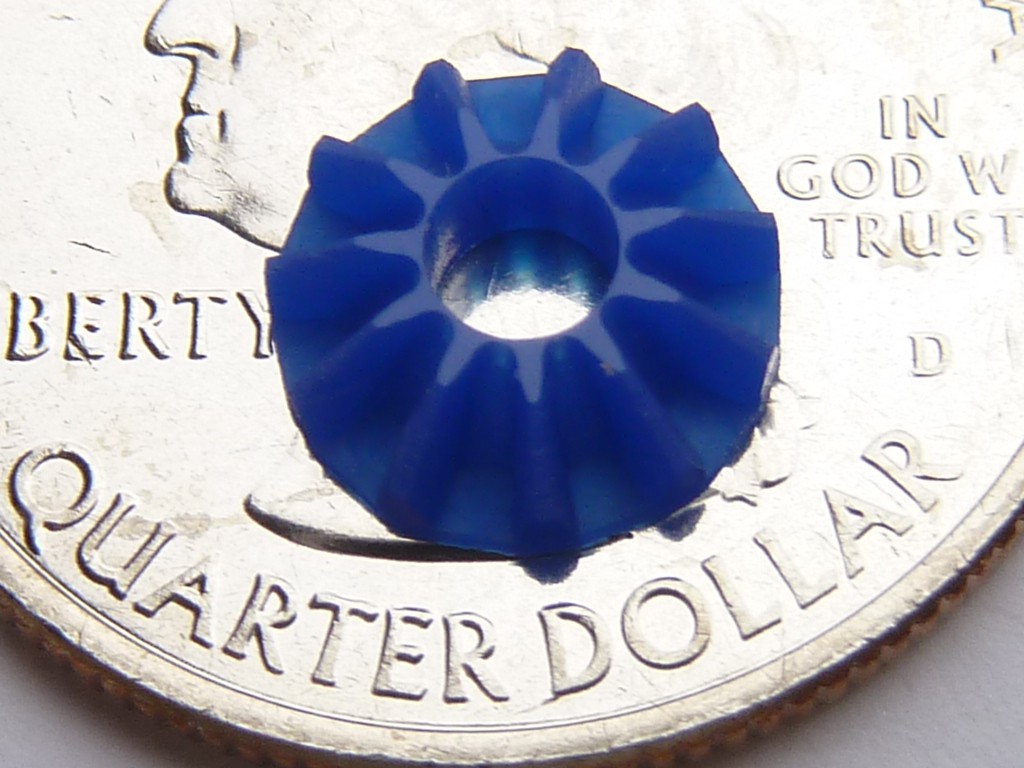

- Click through the gear and circuit trace images for videos

- Both of these videos were made using a generic Dremel-like rotary tool for a machine spindle

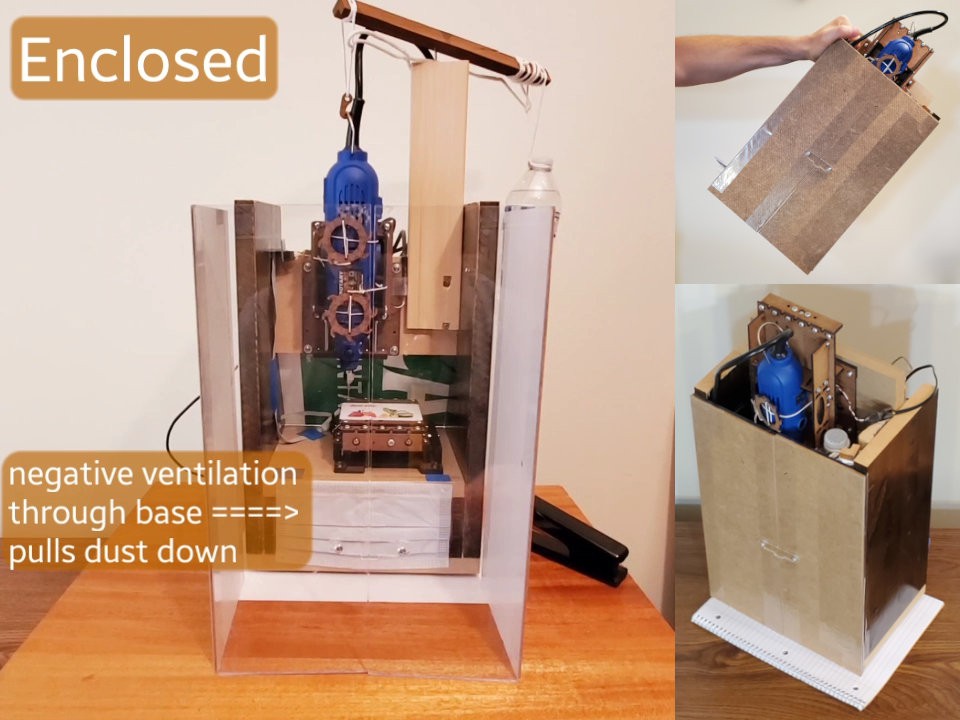

"table-top use and shelf storage in home vs. fixed installation in garage or shop"

With just a little more attention to constructing the frame, again with found scrap, it can be made with "doors" that close up close for storage or unfold into an enclosure, A vacuum drawing through the base pulls floating dust down into the enclosure for clean tabletop operation. The telescoping action of the slides gives the parked machine a compact footprint smaller than a letter/A4 sheet of paper.

Stapler for scale; banana was down.

Click the image below for a video showing setup & teardown.

The contest FAQ and Rules include overlapping lists of criteria to be considered for assessing contest entries. A unified set of criteria and notes in response follow.

Is this a unique solution to a particular challenge facing the world today?

Learning “subtractive” CNC machining requires hands-on experience. Recent pandemic-related restrictions have curtailed necessary access to machines for learning. CNC machines available for personal ownership tend toward exclusively high cost or to sacrificing much of the precision that would characterize a learner’s experience of using a “real” CNC machine. And cheaper CNC means more people learning organically and making more kinds of things.

As far as I know at this point, this really is

- a unique combination of trade-offs and results that

- extracts much better precision from much less hardware and material to

- significantly lower the entry cost for a maker-minded person at home to

- build and operate their own CNC machine that

- behaves enough like a scaled down CNC mill to

- make small things with precise features and to

- directly engage a valuable subject that requires doing to learn.

Also the whole includes parts that

- could prove useful in other applications and which

- I don’t recall seeing anywhere else

How effective of a solution is the entry to the challenge it is responding to?

For the 3D mill

- HaD podcast 136

- “I’m frankly shocked by the quality of the parts coming out of this”

- “He gets crazy good results”

- “..you might be looking at…3018 mills...he does better than that”

- “in the sub $200 price bracket … I would go this way”

- demo videos: gears, PCB, ?aluminum?

- materials *less than* *lowest cost* 3018-class ad I’ve seen

- assuming access to laser cutter (e.g. school, library, hac/makerspace, etc.)

- parts for assembly, not just plans for fabrication

- for the principal mechanics

- required frame is given as plans for fabrication, but may be crudely constructed of crude available materials.

- minimized non-monetary costs

- small, and can be packaged for practical convenient storage and setup-up only for active use with effective debris containment and simple cleanup in non-shop living space

- can bring real practical hands-on actual making parts CAM learning opportunity into home living space

For a single linear slide

- as a headline: over 10kg under 10um for under $10

- demo video - with handwheel - very repeatable (12x in a single take first try) inside +-5um with 30lbs load

- extremely low cost - just a few $ for handwheel drive if all new purchase materials

For making anything from laser cut flat material

- screw in split tab intrudes less into interior area of parts

- uses short screw only vs longer screw and nut

- can be more robust than press/snap fit

For realizing actual low backlash with low cost linear actuator

For robust tool clamp from simple flat parts

Early dev stage: low cost high speed spindle

- front end bearing

- dynamic balencing?

How thoroughly documented were the design process & design decisions?

tl;dr: tried an idea for a least possible step up from a CD/DVD optical deck and it worked so I kept going -- here's the one big read.

I think I can fairly say: documented more thoroughly, or at least with more words, than most people will want to read.

- starting from #CDCNC (also Hackaday.com and HaD podcast 082)

- note re transition

- continuing through >30 log entries at #Minamil: a minimal CNC mill. And friends.

- with a sidebar at #"Desk Accessory" CNC Milling Machine

- since the start of "Challenge 3", log entries on this project

Or a little more selectively:

- about design process & decisions

- the X and Y that were -- review before redo

- progress but frustration

- dense

- did I say frustration?

- some of the basic ideas that seem to be working -- extended review

- so why go vertical when horizontal was such a win before? -- current since HaD Prize contest start

- about an unexpected major problem

- XY table wroks!

"Unexpected problem: the XY axes don't handle a descending load well but chatter."

- backlash, chatter and fine parallel finishing

- homework

- thank you Orang

- XY table wroks!

- about a simplification that became a spin-off sub-project

- about circuit board milling

- second look at PCB milling: looks promising

- milling T/SSOP breakout - 065mm pitch -- current since HaD Prize contest start

- useful tssop 8 breakout almost -- current since HaD Prize contest start

- teaser...

- about failure

- about performance/capability testing

- "mill" or "router"?

- naming the project/instance/class -- last paragraph

- compared to what? -- end note 1

How ready is this design to be manufactured?

For either the 3D CNC design or a single linear slides for use in other applications:

- It’s very ready for someone to gather specified parts and follow detailed instructions to assemble a unit.

- Kits of parts would be (relatively) trivial to “manufacture” as a matter of bulk purchasing a small number of SKUs, cutting sets of laser cut parts, and kitting.

- Elements of this design that favor end-user assembly of one or a small number of units with very simple tools – specifically the apparently novel method of building structural elements from flat material and screws – could be refactored for volume production while retaining the apparently novel mechanical & structural elements that enable the apparently unique capability/cost point of this design.

- In the case of manufacturing a sufficient quantity, whether kits or turn-key, the motor+screw unit could be made more optimal for this application. For example, an available variation of the motor+screw unit, apparently produced with similar tooling, incorporates a 20mm motor of the same type as the 15mm motor incorporated in the motor+screw unit used in this project. While other differences disqualify that particular variant, I think it suggests that a manufacturer has already done most of the setup to produce a torque-upgraded motor+screw unit suitable for this application. I expect upgrading the motor size from 15mm to 20mm would significantly expand practical capability for relatively smaller increase in cost (at sufficient volume).

How easily can this design be implemented by other people in future projects?

"Easy" is a primary project goal!

To be clear, I expect this to continue as a DIY project rather than a turn-key consumer item ready to chug out all the best parts on delivery. By "easy" I mean easy for hack-ish people with aptitude for assembling something from pieces, and then learning a tool that returns delayed gratification for initial patience. That said, making it easier for more people to get started on the 3d CNC “subtractive” learning curve for is also a primary project goal.

And here's the how:

- make yer own! (that took a while...)

- Low(est?) Cost Reproducible 3-axis CNC Mill -- Instructable

- parts prices

...And...

- I've broken out the linear slide mechanism as its own design and sub-project to make it readily re-usable in other applications.

- The slide CAD includes, optionally, the secure tool clamp made from flat parts and string. I don't recall seeing that anywhere else.

- The screw-in-tab-in-slot joints may be used in other projects for joining cut flat parts with minimal intrusion into the interior areas of parts.

- The anti-backlash adjustment with laser cut parts and a paperclip may be used in other projects

How complete is the project?

Two answers:

- It works well right now!

- I think this project has lots of potential for further development!

- validate buildability

- improve build documentation - try video

- given rising price of the specific CH-SM1545 motor and falling prices of similar but longer generics: adjust dimensions to fit the longer screws which are no longer much more expensive and apparently available from more sources. (oh, heck yeah - price bumped again)

- optimize flat part details to reduce commercial laser cutting cost

- adapt for more expensive but faster-cutting material, e.g. acrylic, to net reduce commercial laser cutting cost

- try again 2x motors for X & Y - first try effective when synced but too easy to un-sync; try again with limit switches & soft limits

- test idea for low-cost high-speed spindle made with similar laser cut hardboard construction

Paul McClay

Paul McClay

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.