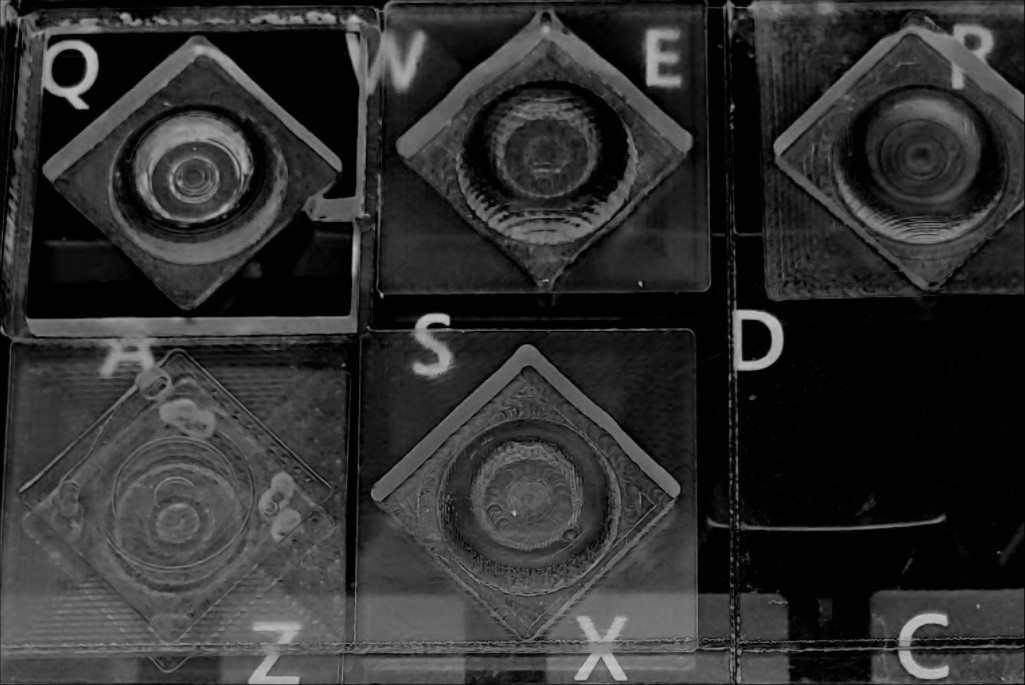

Apart from an initial attempt and unsurprising failure to cut out the part at Q, I've just been trying to cut clean pockets without trying to cut out parts. The last log ended with the pocket at R which I'm willing to call "pretty good".

So it's time to try cutting a part!

It helps that exactly one month ago Stewart Allen checked in a "wide cutout" option for Kiri:Moto. That solves the cause of predictable failure at Q above (actually the failure is under W) without any other CAM gymnastics.

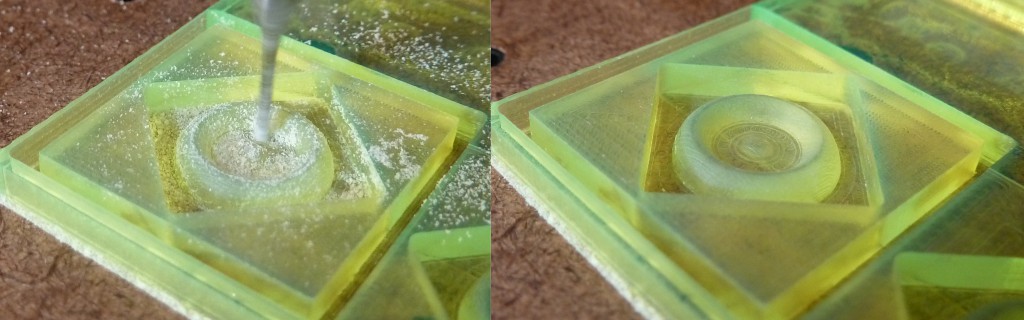

This time I double-stick taped the material in place. Kiri wanted to cut the part outline as part of the roughing operation before finishing the curvy bit. Kiri does support tabs, but I didn't want big tabs and didn't know how unbig the tabs could get without messing up the finishing operation. So, tape.

"Send File"...

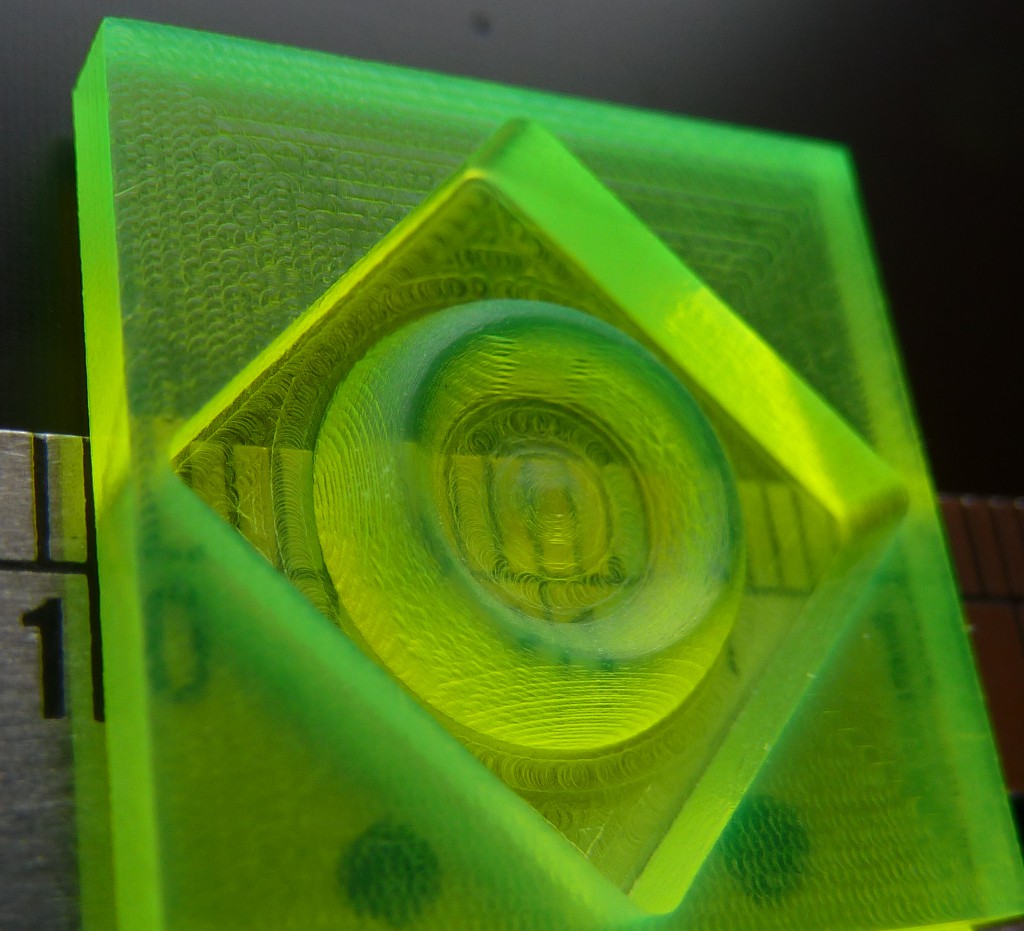

...and this time it worked.

Relative to my subjective hopes/expectations for this project, I'll say that turned out well.

Yay.

Next: try conventional milling without augmented lead screw inertia.

Paul McClay

Paul McClay

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.