This appears to be working well enough to risk saying so.

Little stepper+screw units for $5 shipped got this project started. That price has multiplied while the cost of longer but otherwise similar units has come down some. So I wanted to try stretching the XY dimensions a little to fit the longer screws.

One thing.

Simples, right? But people asking about 3d printing and Micro Center dumping Enders. But design for 3d printing is different. But doable. But the frame/box limits longer X travel, which doesn't actually prevent testing. But thinking about different frame. XY works but not great so rebuild, and thinking about accessory stuff that I could fit into the box but haven't yet but can start but halfway = finish before more actual testing, which wasn't great on the 2nd try either. Etc. I was getting a little fretty about dumping time into a new thing that wasn't matching the performance of the old thing.

Test, rebuild, digress, test, revert, test, digress, rebuild, test, tweak, test, ...

I think it'll be ok.

| "One Thing" | ||

|---|---|---|

| short leadscrews | ➽ | long (less short) leadscrews |

| 55mm x 55mm work area | ➽ | 75mm x 75mm work area |

| laser cut 2D parts | ➽ | 3d printed 3D parts |

| 100mm rods | ➽ | 120mm rods |

| many screws | ➽ | not so many zip ties |

| compact stowed footprint | ➽ | compacter stowed footprint |

| exposed electronics | ➽ | enclosed electronics |

| unreachable hold/resume/abort & motor power switch; invisible indicator LEDs | ➽ | reachable hold/resume/abort & motor power switch; visible indicator LEDs |

| "compact" but: add'l acquarium air pump + hose over the side, two power bricks, external switched AC for spindle, blower & vent fan (four power cords + spindle signal to hacked power strip) | ➽ | integrated chip blower, DC power, switched AC outlet for spindle (not actually in there yet), chip blower DC switched with spindle, vent fan DC switched as "coolant" (one power cord) |

Two projects

But really, this is two distinct and very different projects: the CNC mechanics and the frame.

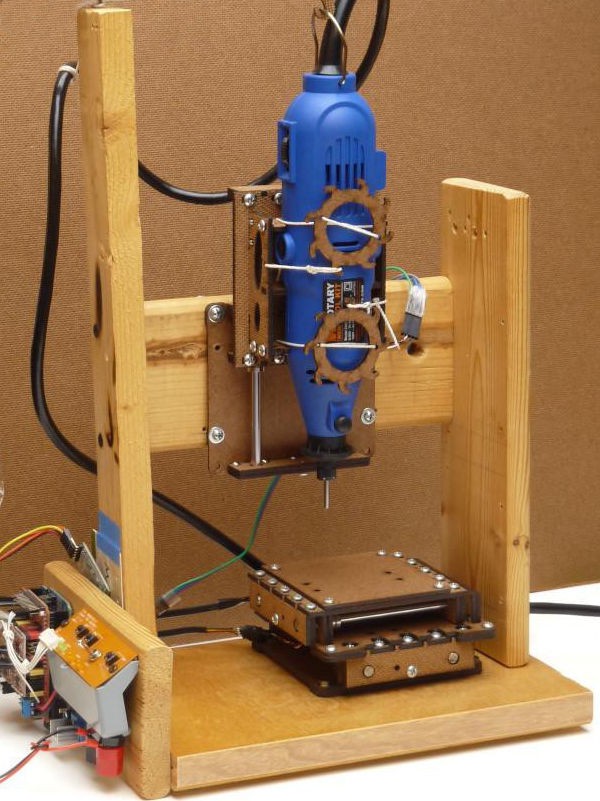

The frame can still be dirt simple if you just want the CNC stuff to work.

(simple frame pic cropped/edited to (mostly) hide the obsolete counterweight)

Fancy packaging is already its own project: #"Desk Accessory" CNC Milling Machine. That project has been pretty static so far but this iteration brings it more to the front. More about fancy packaging will probably appear in that project instead of this one here.

I haven't decided yet whether to continue writing about the 3d printed CNC mechanics here, or to start a new project for that. It's basically the same mechanics, but also a significantly different "project" if you want to build one. I do plan to post at least STLs, maybe CAD, and info for building one.

Paul McClay

Paul McClay

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.