To get the machine operational I needed at least 6 optical channels for controlling it from a for the controller and the notebook noise-safe distance. Step and Dir channels for two stepper drivers and signals to turn on the arc starter and arc power.

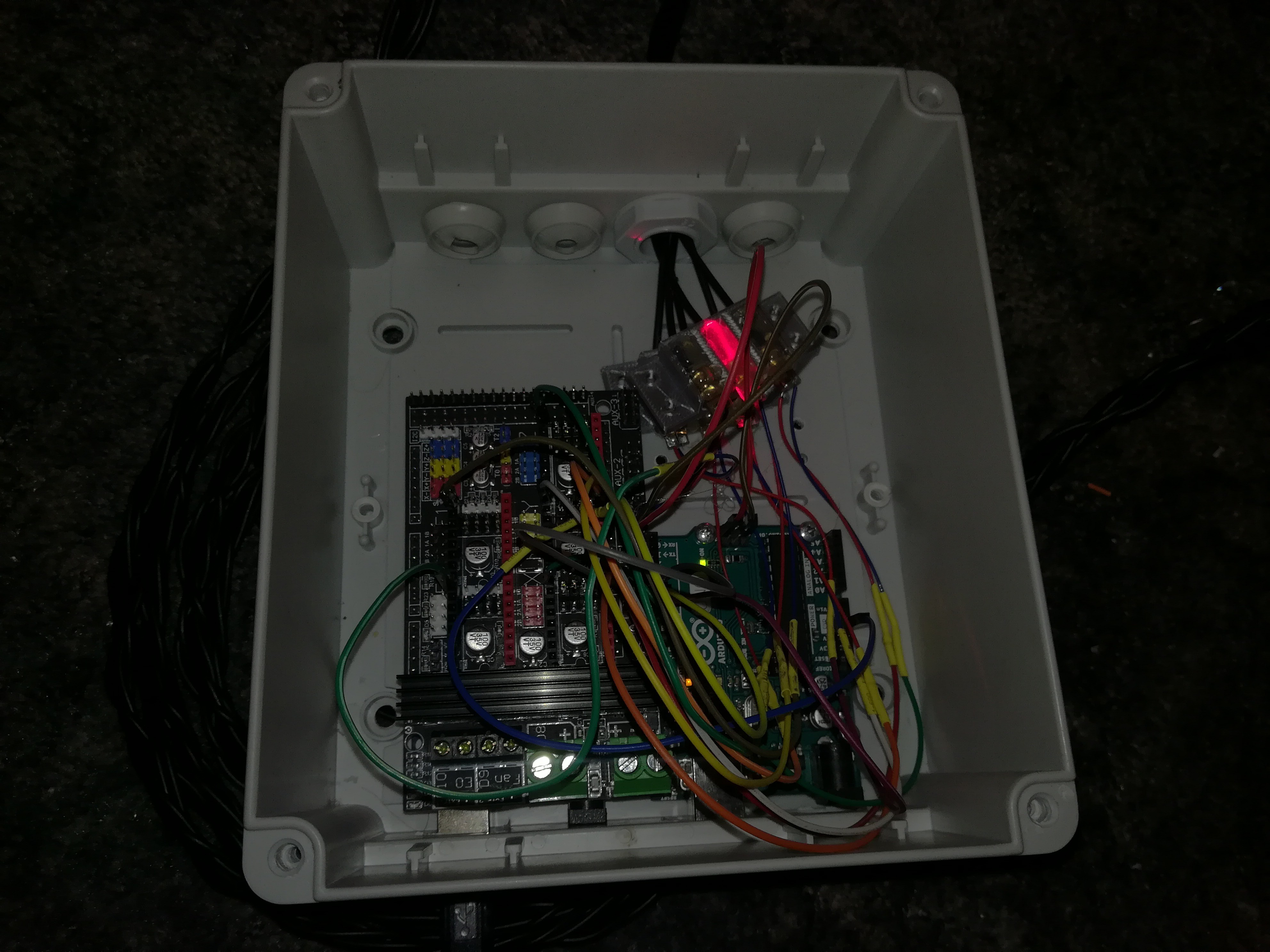

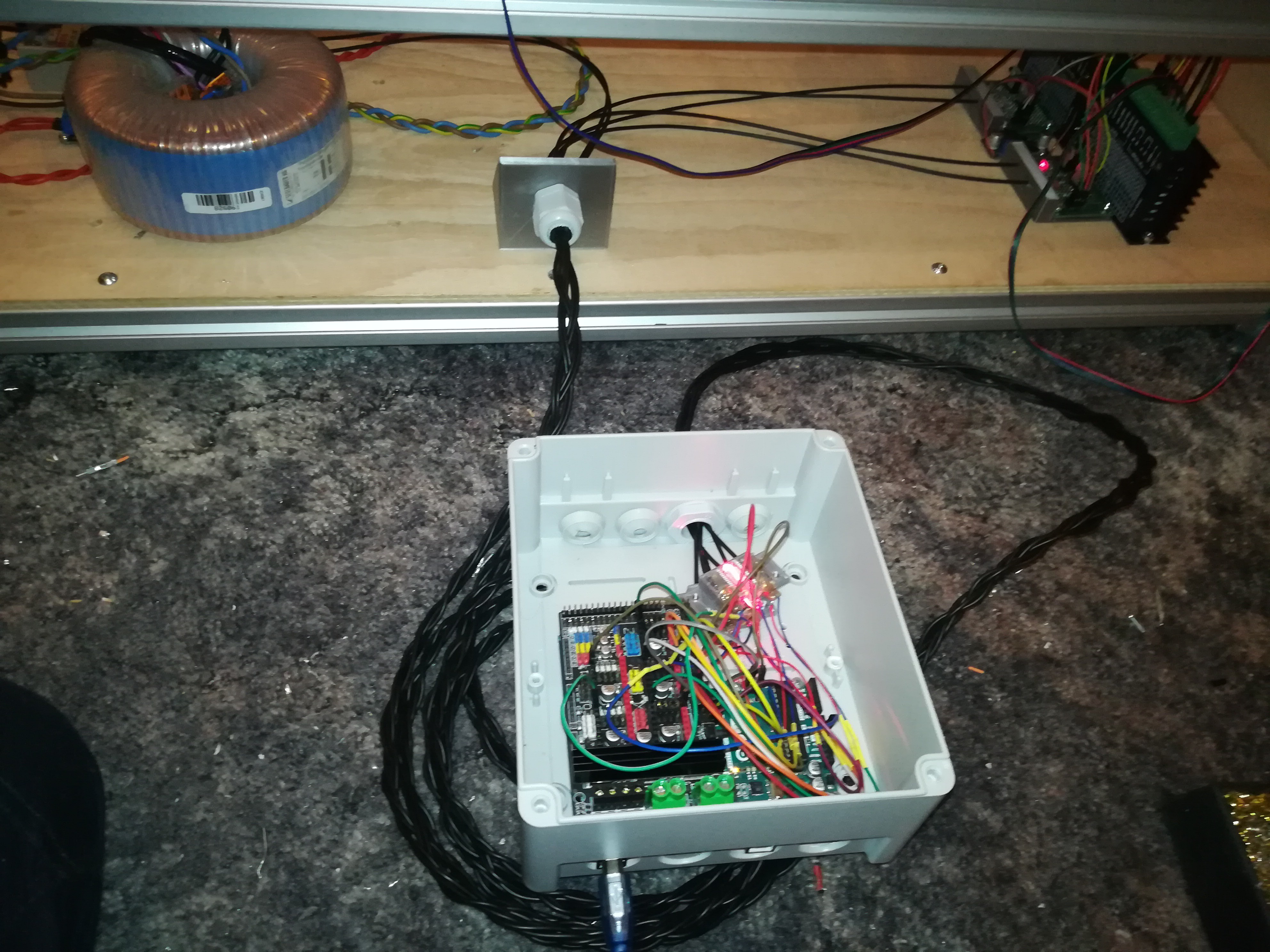

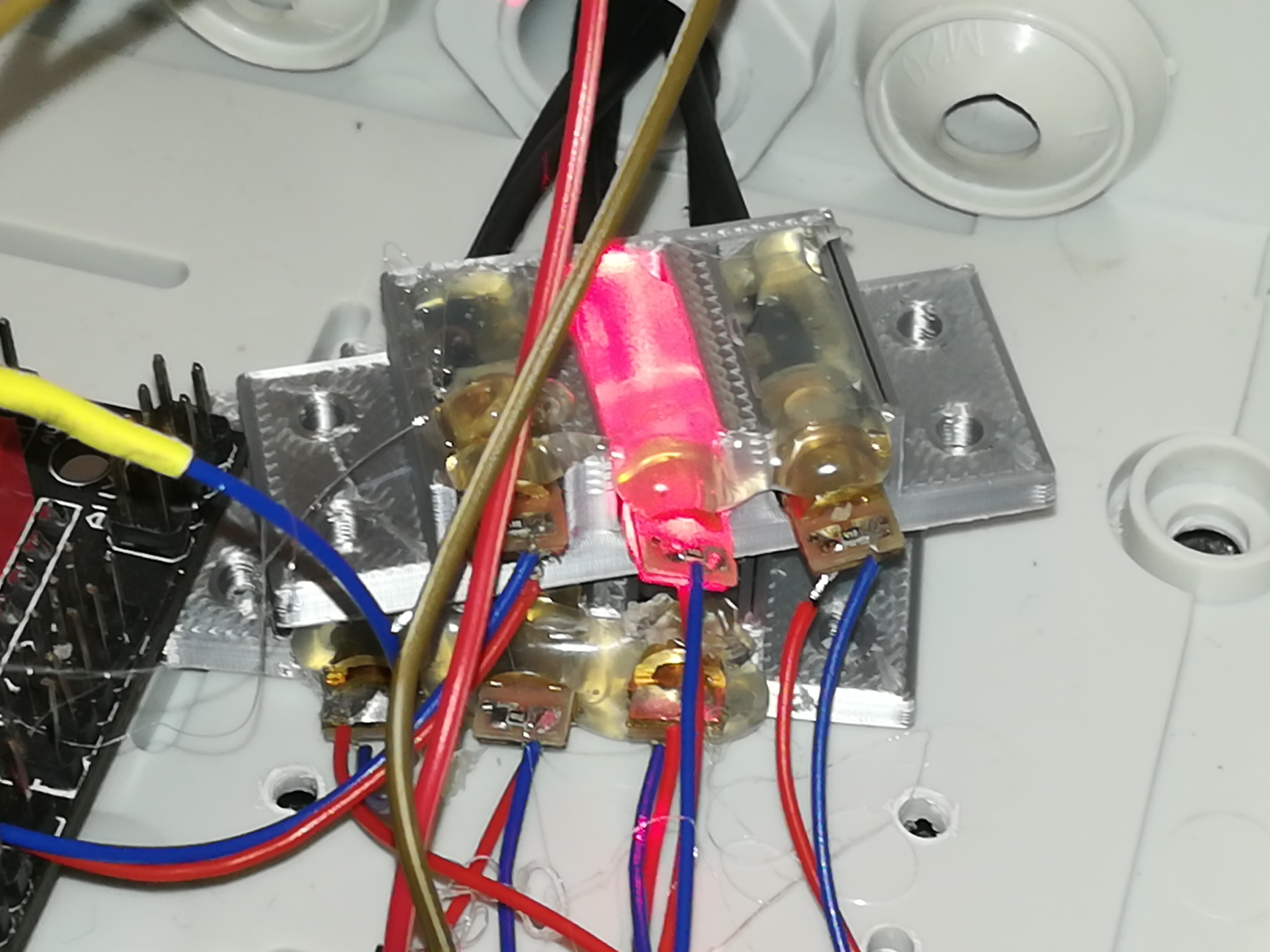

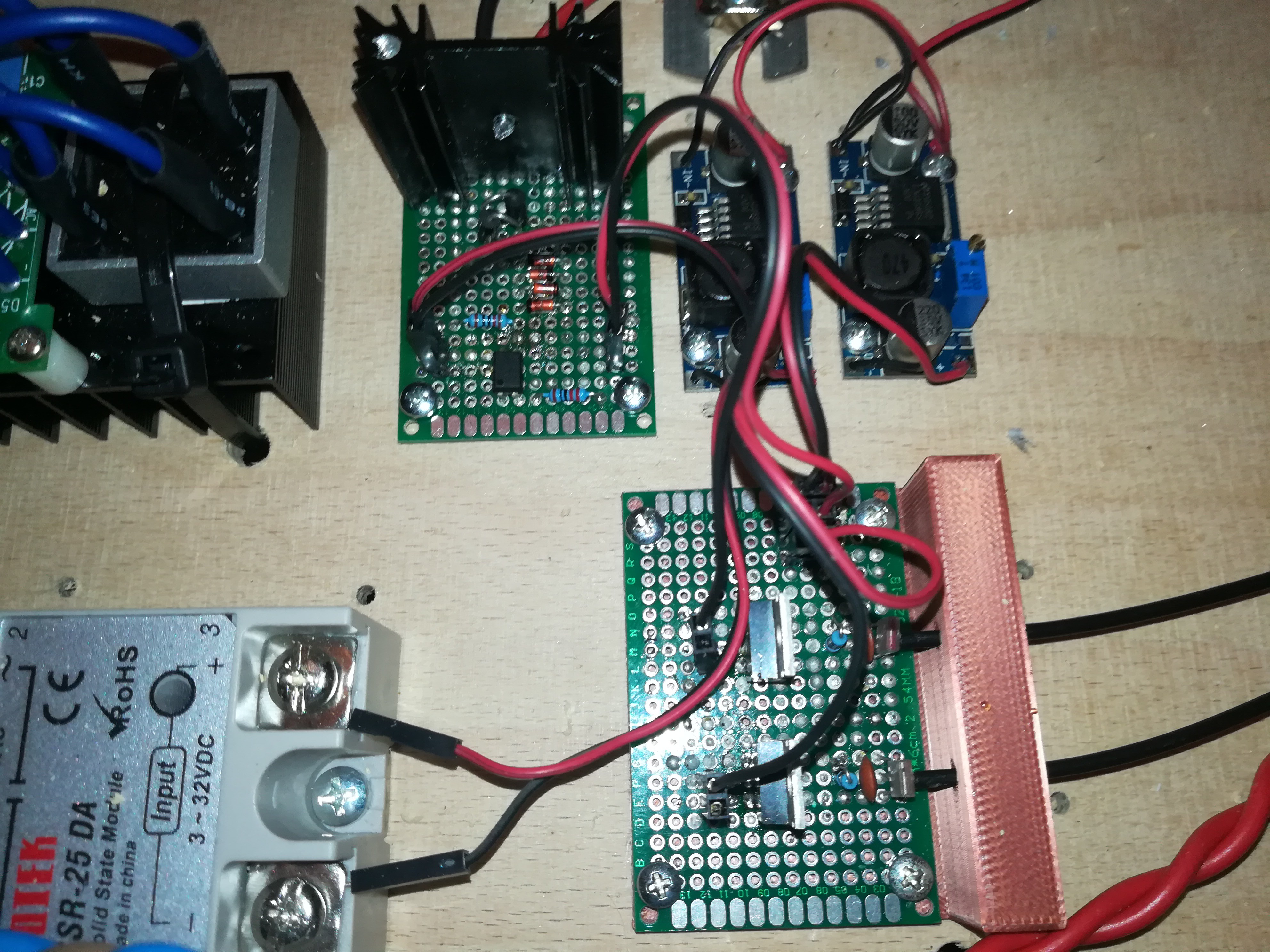

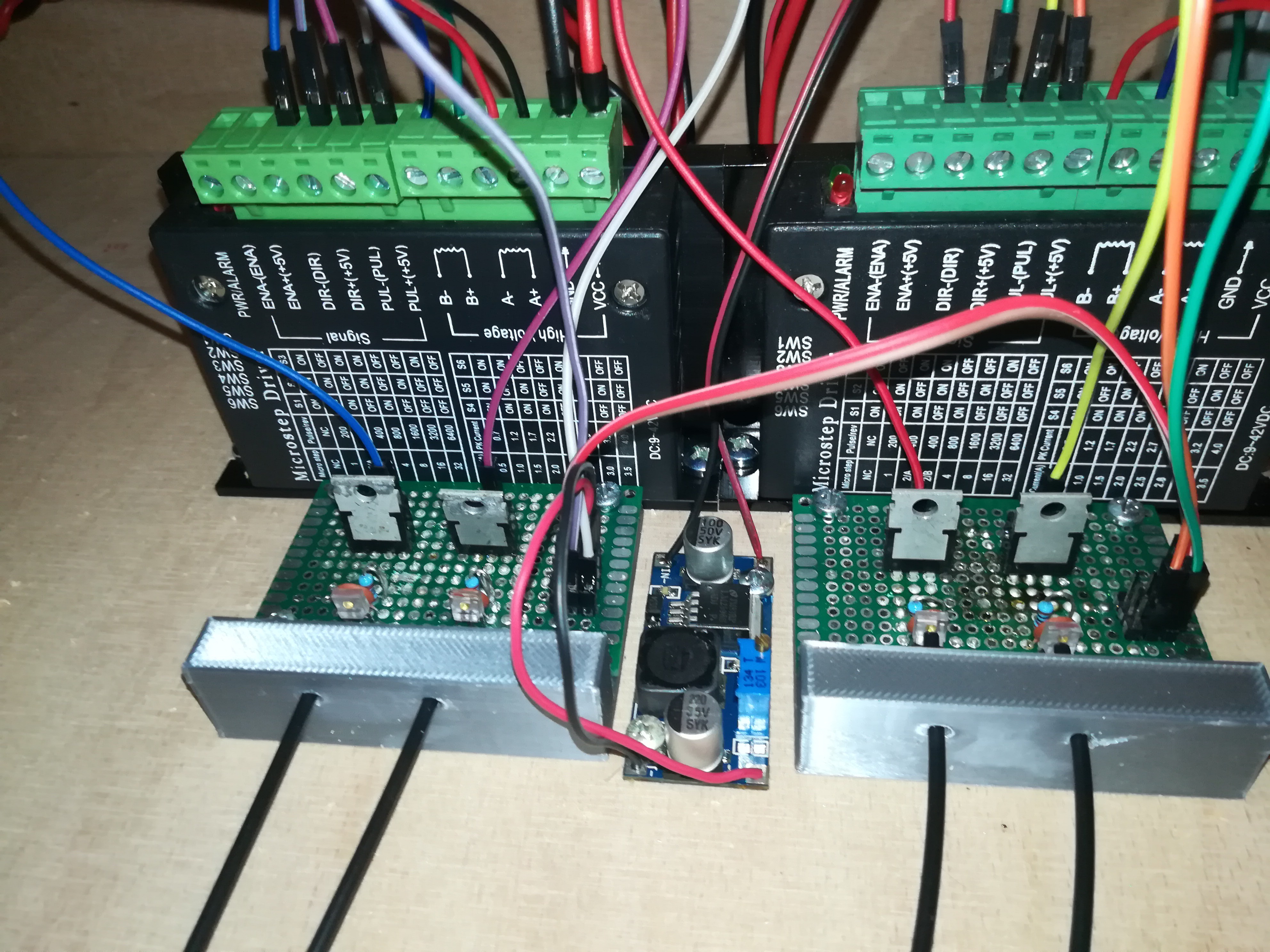

The system works very reliable and with the new single pulse arc starter the motors are no longer noticable affected by the arc starter, even though my TV turns still on and my notebooks screen output crashes when it is too close to the arc. The optical cable is a cheap 25m toslink one that I cut in six 4m pieces to have enough room between the notebook and the printer (about 2m). The controller which is an Arduino Mega + Ramps 6 plus is connected to the lasers which are hotglued in 3D printed brackets which also hold the fiber cables. At the other end are also 3D printed brackets with no-name "ISO203" unmodulated laser receiver modules. I soldered the parts from the module (sensor, capacitor, resistor) to a pcb to prevent the sensor from false readings which it has sometimes due to vibrations when placed in the original mounting slot.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.