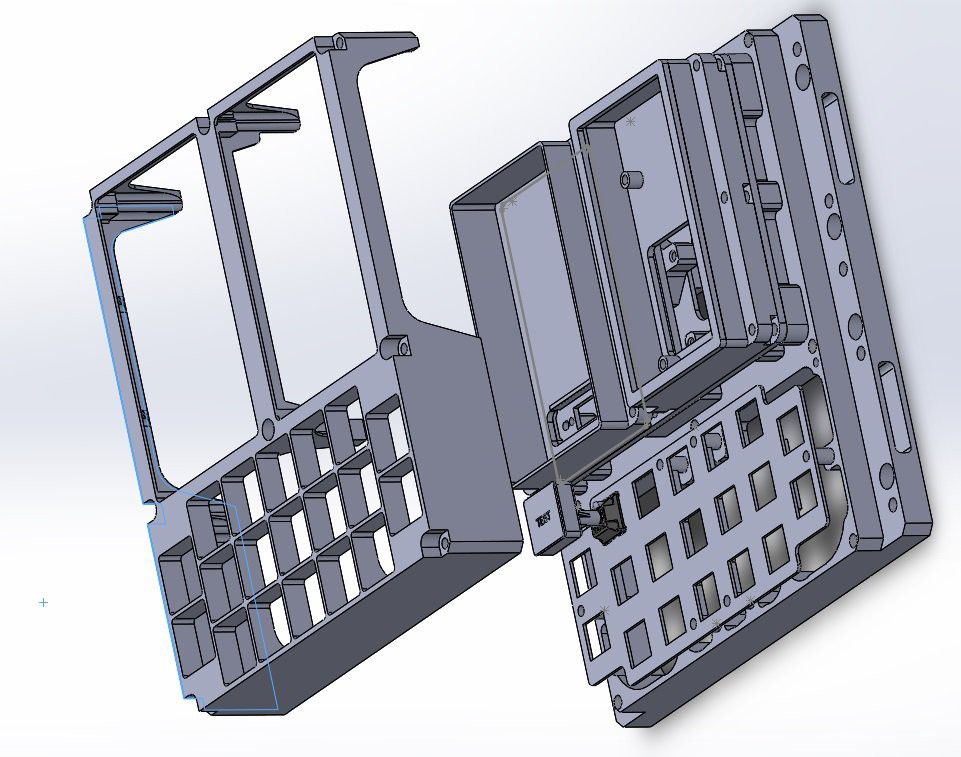

As I didn't have access to a CNC mill (and it's been a long time since I used one), creating a replica out of aluminium was out of the question for now. Using a 3D printer seemed like a good option, as I could also test-fit my parts. Mistakes will also be much cheaper.

I also want the replica to be fully functional. While the external features could absolutely not be touched, I had to modify the internals to accommodate my keypad and indicator design. The main housing's internals could also be heavily simplified as only a Raspberry Pi and a handful of components were going to be used.

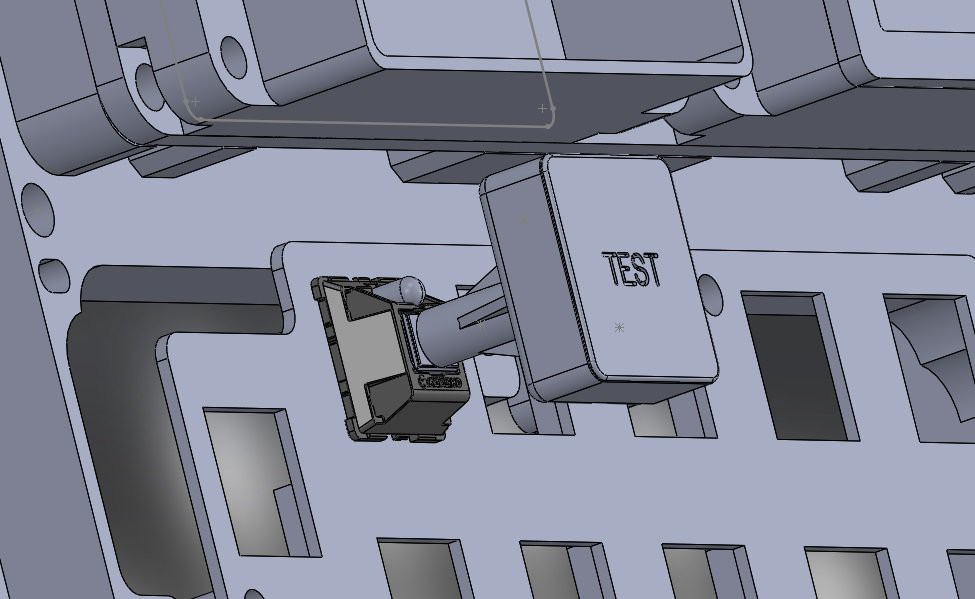

A plate had to be designed to hold the cherry MX switches, and the non-functional model of the indicators were "carved out" for my electronics.

The mounting plate hole size were also modified to press-fit threaded inserts.

M.daSilva

M.daSilva

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.