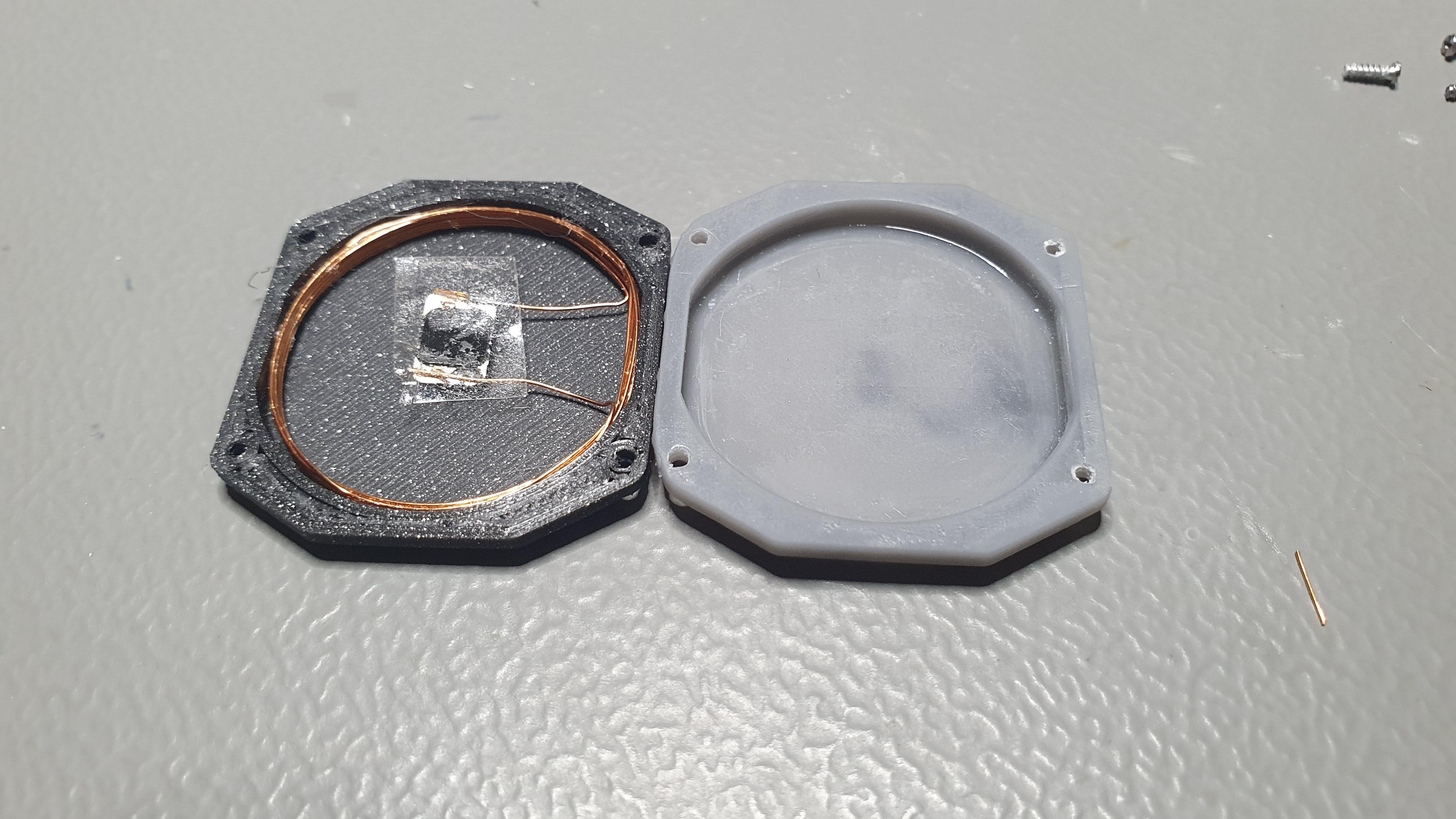

While I was waiting for the necessary instruments for the front plate (2mm thick double sided tape and UV torch light) I ordered a resin printed backplate thinking it would solve the little scratching feeling from the FDM printed one (I know I could have gone with the sending route but hey, I wanted to try a resin printer for once :D).

Not having a resin SLA printer I used an online service to print it. Albeit not being 100% satisfied by the looks, the print actually delivers on the smooth factor. No more scratchy feeling and super comfortable to wear.

I think that this idea cannot go further then this so I'll focus on the frontplate antenna for now. Speaking of which...

I was able to build a working antenna using 0.1 mm thick enameled wire... and it was actually easier than using the 0.25 mm thick one! Unfortunately I'm having trouble in building the glass for the screen using the UV curable resin due to the high temperatures it reaches while curing under the sun. To this end I bought a UV torch light from Amazon hoping it will solve the issue...

Mattia Dal Ben

Mattia Dal Ben

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.