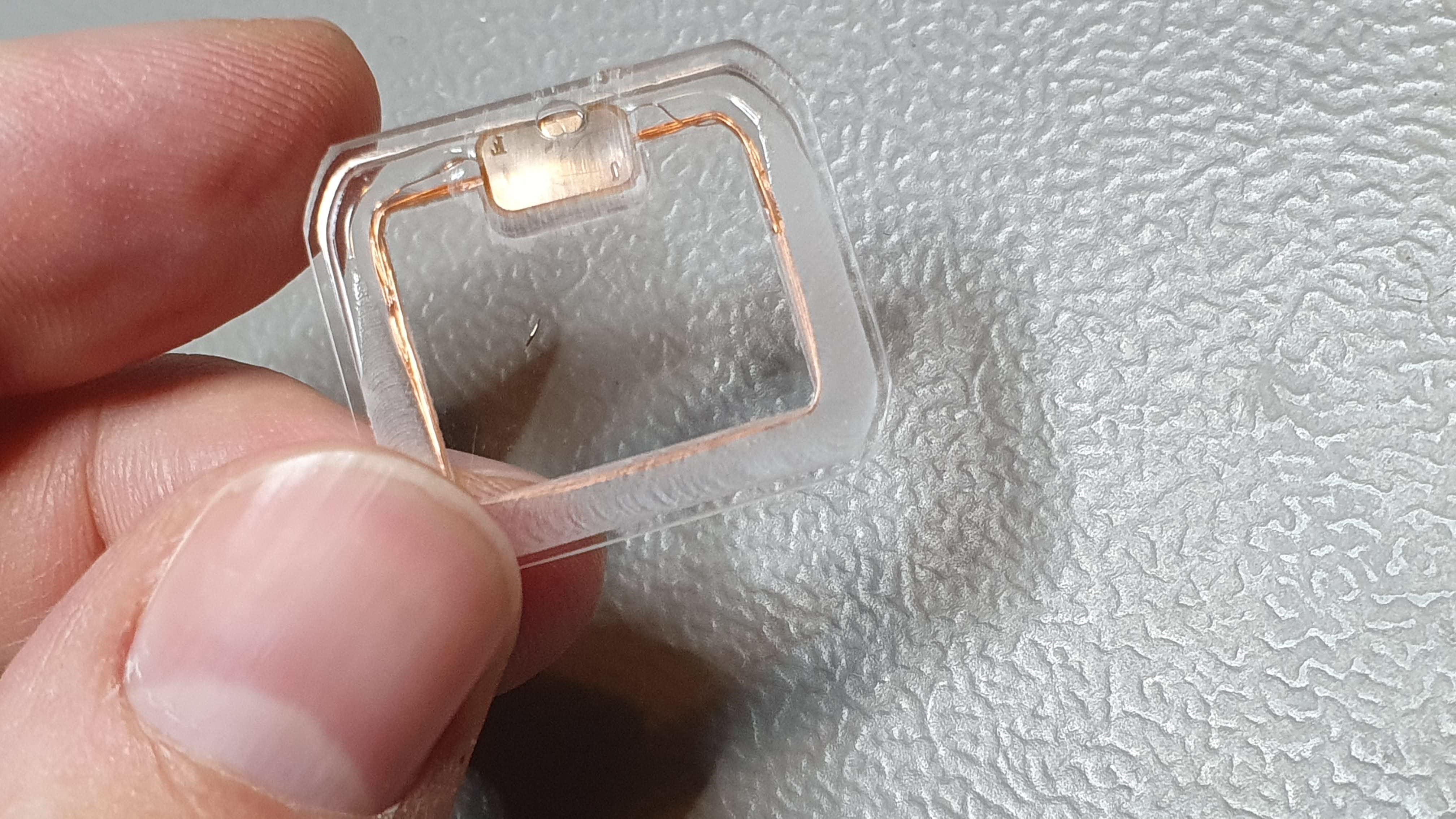

I was finally able to get my hands on some 2mm thick acrylic and test the production process of the antenna I thought.

Let's start with the 2mm thick acrylic frontplate.

This looks AWESOME! (Since I was at it I alsso modded the screen for a darker look).

The matte look left from the CNC machining is really cool and I love it. I'm trying to leave it as is.

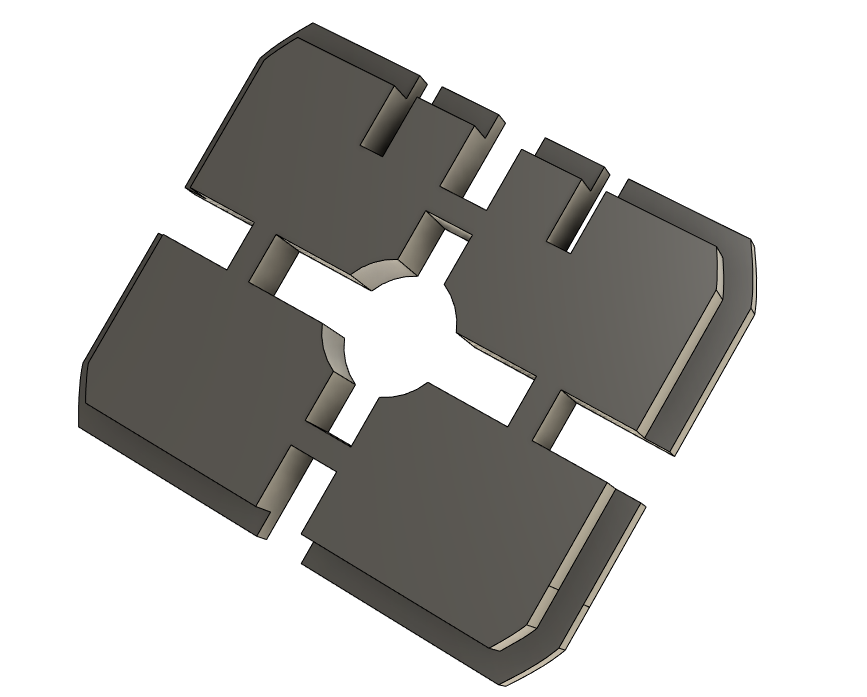

Regarding the production process I designed and 3d printed a guide that can be broken up into parts after winding up the antenna.

This way I was able to buld the antenna on the guide in a much more comfortable way and, once finished tuning the resonant frequency, I was able to break the guide into parts and tranfer the antenna on the frontplate without damaging it.

I then wanted to try fixing everything up using some UV curable resin. That was a bad idea...

I lost the matte look on the top half of the frontplate and it now looks like its foggy. Furthermore some resin creeped on the screen ruining its transparency.

Finally I decided to stop using the resin altoghether and keeping things simple: I will now design the new frontplate without the hole for the chip. It will be just a recess in the acrylic. This way, if things go wrong, I will be able to rescue the chip.

Last thing to do is decide how to mount the frontplate to the Casio chassis. I have two options:

- 2mm thick double sided tape (already bought for this purpose).

- T-7000 glue

The second seems more fit for the purpose at this point. I'll have to try thing out.

Mattia Dal Ben

Mattia Dal Ben

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.