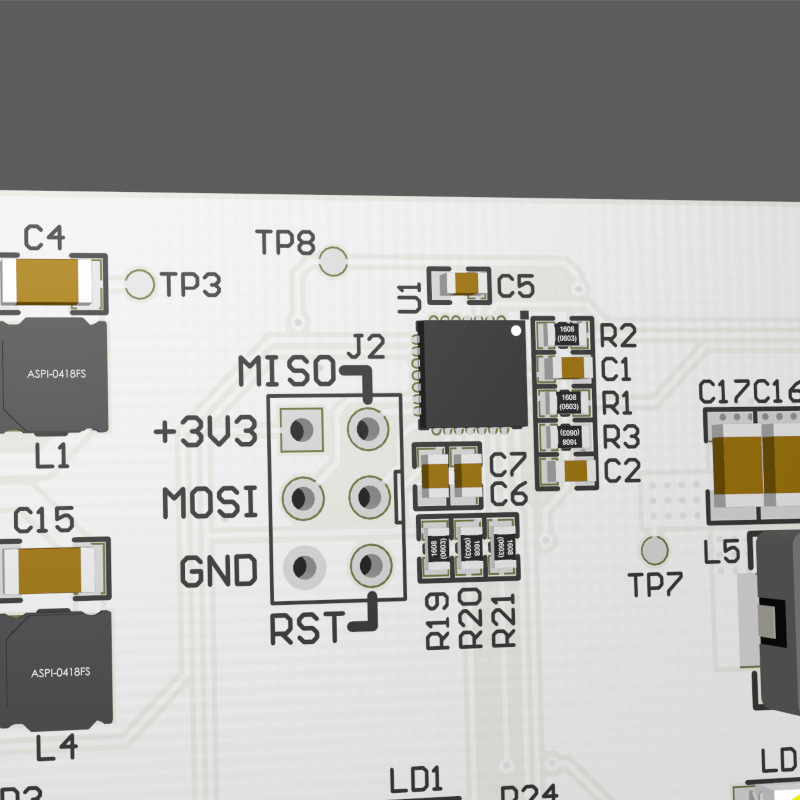

From the economic side, material cost of controller module is around 20$, 365nm LED module 20$ and 15$ for 400nm LED module. There should be also considered 5$ per set(Controller + LED module) for automatic assembly(pnp) and production testing.

Good news is that with more modules being produced the price of material will fall. Good estimation would be 30-50% on quantities of more than 100.

Rundown of components needed is provided in BOM. Future wise there are also savings possible with regard to component choice. Example being pricey Semtec "SSM-106-F-DV" connectors and Keystone 1042 battery holders.

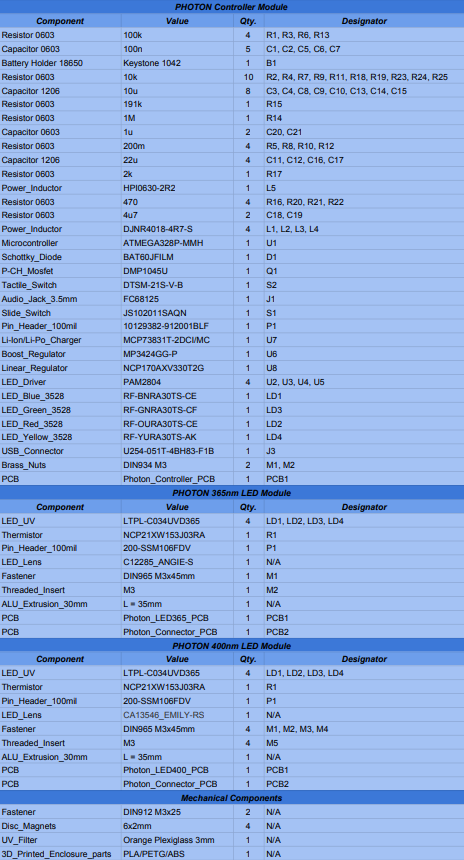

If a larger quantity of modules are needed, to optimise the process PCBs can be panelized. Replacing TH components with SMD versions would also reduce manufacturing time and cost since they can be placed by PnP machine and eliminates soldering by hand by human worker. Here is example of panel with V-cut, industrial edge and fiducial markings for PnP and Stencil printers.

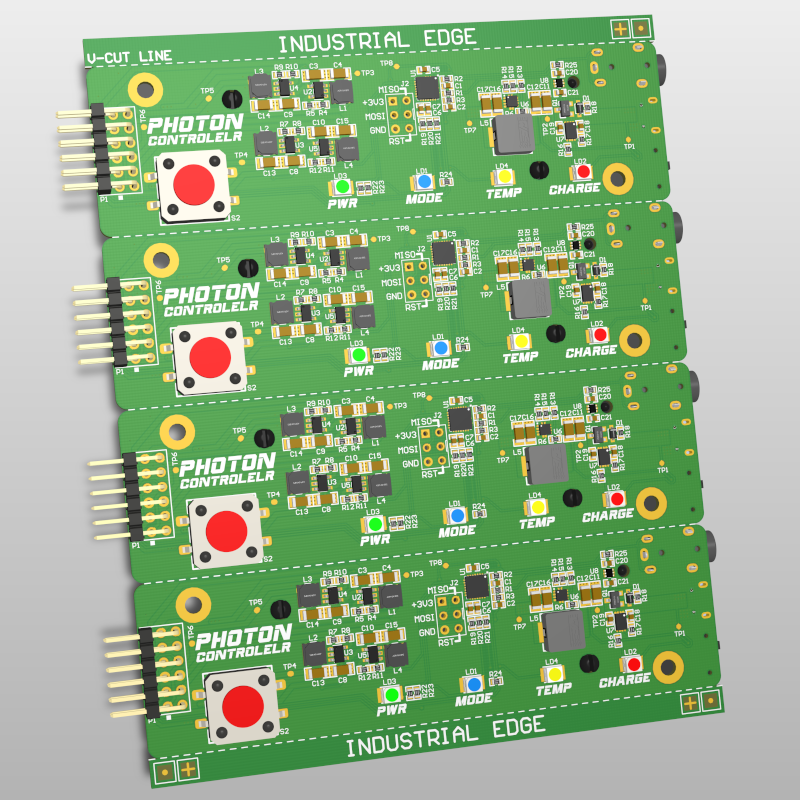

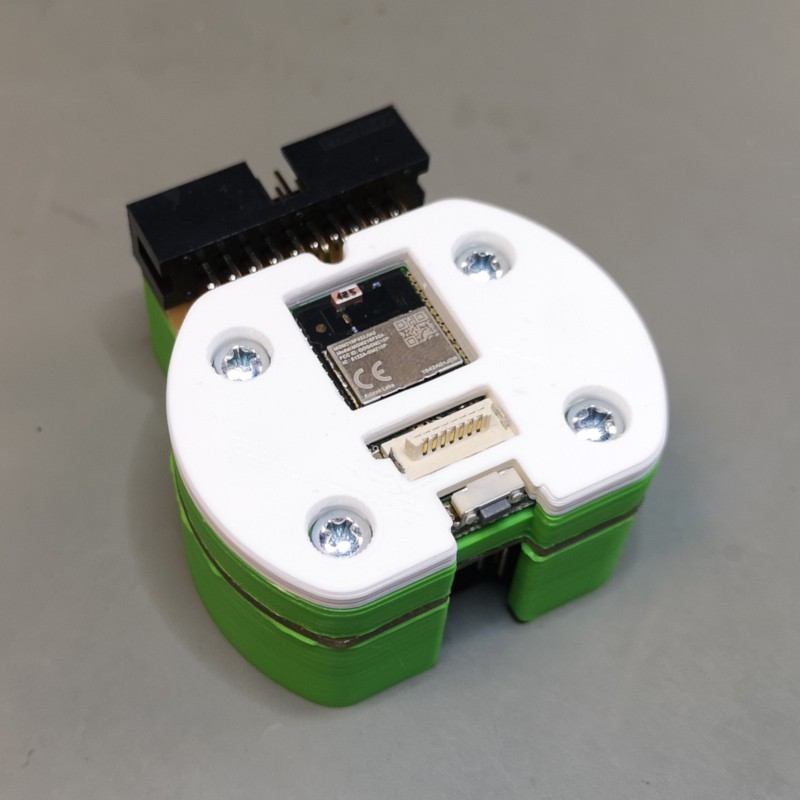

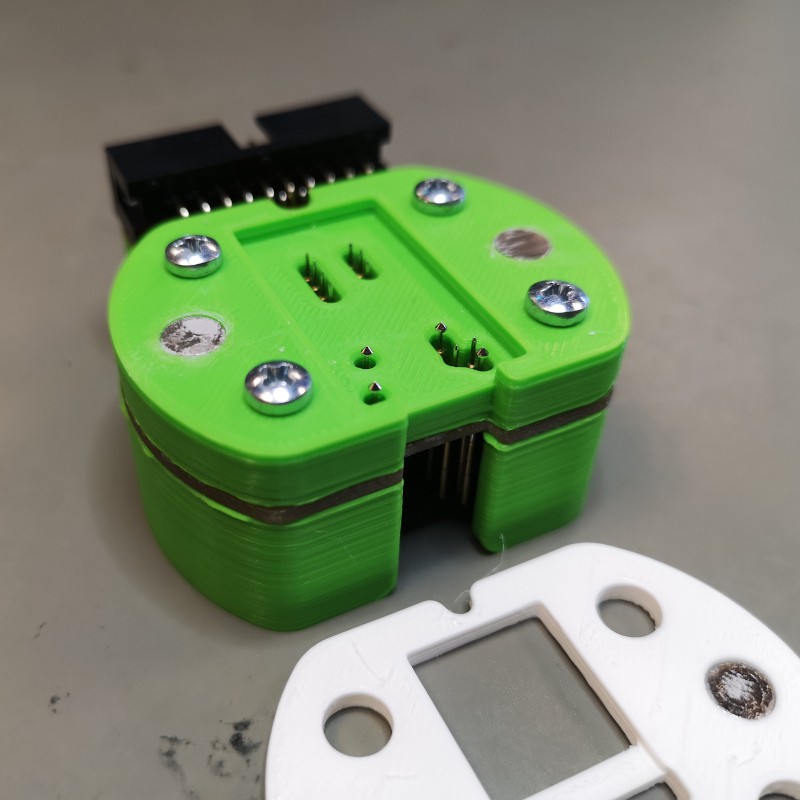

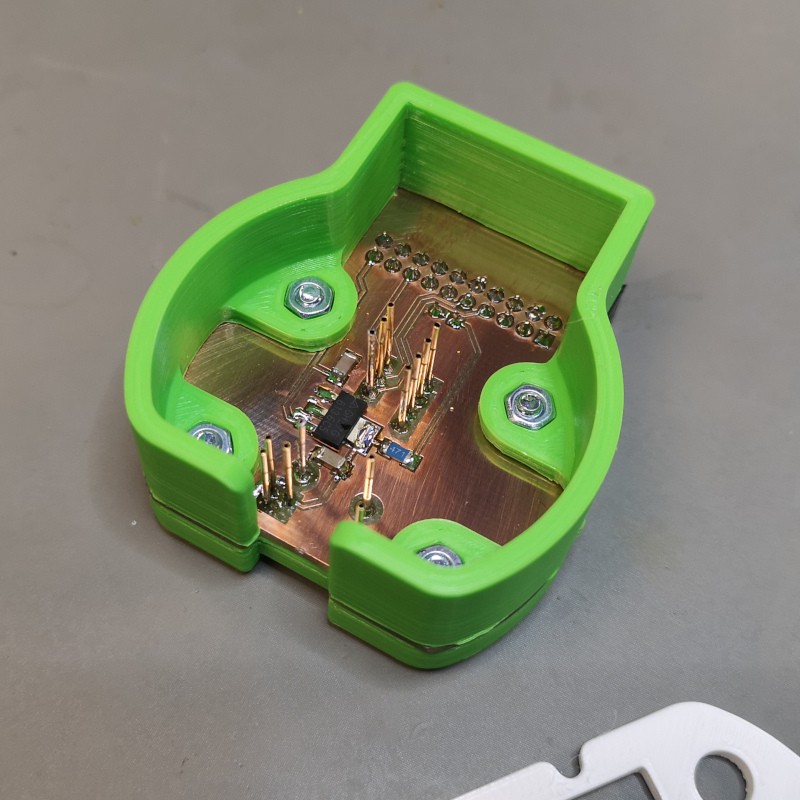

On the PCB there are also Test Points. Test points are used to automate PCB testing and verification. If simple "bed of nail" test jigs are used, cost of manufacture and lead times can be short short. Here is picture of onboard test points for generic 50mil pogo pins and simple test jig that I made for different project. Similar system can be used for testing on this project.

|  |

|  |

Mile

Mile

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.